Core Materials Technology for the New Energy Vehicle Industry

Batteries, Semiconductors, and Laser Ranging Materials

1 Introduction

As awareness of the severity of environmental issues continues to grow, new energy vehicles are increasingly replacing traditional fuel-powered vehicles, with the market size demonstrating a sustained growth trend. The performance optimisation and technological advancements of battery materials—the core components of new energy vehicles—semiconductor materials for intelligent control components, and laser ranging materials for environmental sensing components have gradually become the core areas of industry competition.

Battery performance, as the core power source, is one of the most important factors consumers consider when choosing new energy vehicle products. The balance between battery capacity and volume/weight directly determines the vehicle's range; meanwhile, the risk of thermal runaway is the most critical safety hazard for power batteries, and the heat dissipation performance of battery materials significantly impacts the vehicle's safety factor. Automotive-grade semiconductors face compound challenges related to efficiency, computing power, and supply chain issues. Traditional silicon-based insulated gate bipolar transistors (IGBTs) suffer from high switching losses, which impair the energy efficiency of electric drive systems. Additionally, the computational power required for autonomous driving (>100 TOPS) is constrained by the low yield rates of automotive-grade advanced process chips (yield rates below 50% for processes below 7nm). Global automotive microcontroller (MCU) production capacity is highly concentrated among a few manufacturers, resulting in weak supply chain resilience.

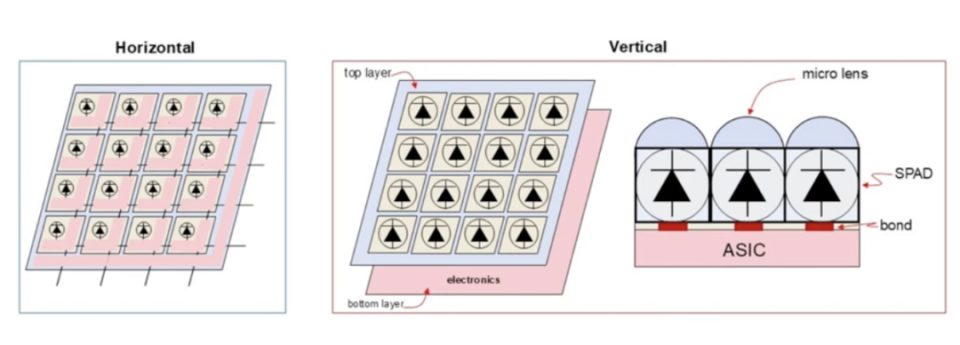

Solutions focus on wide bandgap semiconductor materials: silicon carbide (SiC) power modules can reduce electric drive losses by 50% and increase range by 5%; the industry is advancing the mass production of 6-inch SiC substrates to enhance supply stability. The core challenge of lidar lies in balancing accuracy and cost. Mechanical solutions offer high accuracy (±2 cm) but cost over £5,000 per unit; solid-state solutions (such as Flash/optical phased array) experience a 40% reduction in ranging capability under strong light conditions. Technological breakthroughs depend on direct time-of-flight (dToF) chip integration: using vertical-cavity surface-emitting lasers (VCSELs) and single-photon avalanche diode (SPAD) arrays to achieve millimetre-level ranging accuracy (e.g., the VL53L8 chip). The application of wafer-level optical components has driven costs down to the £500 range, making large-scale LiDAR deployment feasible. Multi-sensor data fusion is the key path to achieving high-reliability autonomous driving.

Fig. 1 New Energy Vehicle Batteries

2 Power Batteries: The Evolutionary Changes of Energy Carriers

2.1 Material System Iteration: From Liquid to Solid

Comparison of liquid lithium-ion battery technologies:

Lithium iron phosphate (LFP): Offers high safety and low-cost advantages (material decomposition temperature >500°C), but faces energy density limitations (typical value: 160–180 Wh/kg). Low-temperature performance is constrained (-20°C capacity retention rate <70%), but it exhibits excellent cycle life (>4,000 cycles at 80% capacity retention rate).

Ternary Materials (NCM/NCA): Significantly improved energy density (220–300 Wh/kg), but poor thermal stability (NCM811 thermal runaway onset temperature <180°C). Dependence on nickel and cobalt resources leads to significant cost volatility (cobalt price fluctuations can reach ±30% per year), and high-nickel materials accelerate electrolyte decomposition.

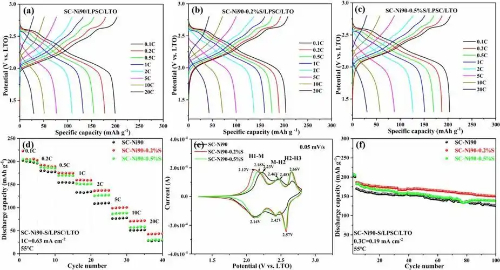

Fig. 2 NCM Battery Life

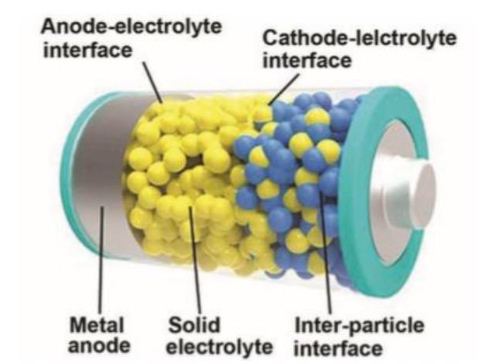

Technological breakthroughs in solid-state batteries focus on intrinsic safety and energy density improvement, but must overcome interface conduction and scalability challenges. Core advantages lie in two areas: the non-flammable nature of solid-state electrolytes eliminates the risk of thermal runaway from organic electrolytes, achieving intrinsic battery safety; the application of lithium metal anodes breaks through the theoretical capacity limits of graphite anodes, enabling energy density potential exceeding 500 Wh/kg. However, key technical challenges hinder industrialisation: solid-solid interface ionic conductivity impedance results in room-temperature conductivity generally below 10^-3 S/cm; the extreme sensitivity of sulfide electrolytes to moisture and oxygen (instantaneous decomposition when exposed to air) severely impedes large-scale production; current material costs are over three times higher than liquid battery systems, urgently requiring supply chain collaboration to address interface modification, atmosphere control, and process cost reduction issues.

Fig. 3 Schematic Diagram of The Layered Structure of a Solid-State Battery

2.2 Structural Innovation and Manufacturing Upgrades

Integrated packaging technology (CTP/CTC) significantly improves battery pack volume utilisation by 15%-20% by eliminating module structure layers. Typical cases show that third-generation CTP technology can achieve a breakthrough in system energy density of 255 Wh/kg. In the field of advanced manufacturing processes, dry electrode technology eliminates the solvent drying step, reducing production energy consumption by up to 30%. Concurrently applied pre-lithiation technology effectively compensates for lithium loss during the first cycle, improving initial efficiency by 5%-10% and extending cycle life. Related process optimisations have been validated through industrialisation.

2.3 Circular Economy: Regenerative Technology System

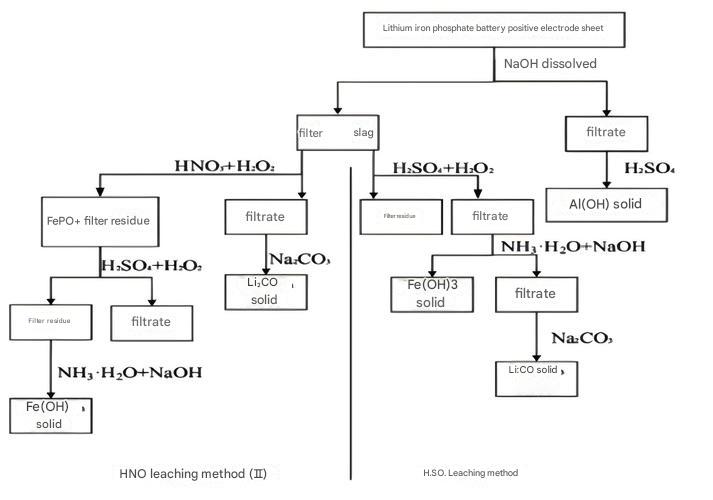

Retired power batteries (with a remaining capacity of 70%-80%) undergo electrochemical screening and reconditioning, enabling their secondary use in grid energy storage systems (with peak shaving accuracy of over 95%) or as power sources for low-speed electric vehicles, achieving a 40% reduction in secondary utilisation costs. In the material recycling process, hydrometallurgical technology employs a sulfuric acid-hydrogen peroxide (H₂SO₄-H₂O₂) acid leaching system combined with di(2-ethylhexyl) phosphate (D2EHPA) solvent extraction, achieving metal recovery rates of over 90% for lithium, cobalt, and nickel, with product purity meeting battery-grade standards (lithium carbonate purity >99.5%). The EU's Battery and Waste Battery Regulation (2023) mandates a lithium recovery rate of at least 80% by 2031, driving the standardisation of global recycling technologies.

Fig. 4 Flowchart of Wet Metallurgical Process for Battery Recycling

3 Automotive-Grade Semiconductors: The Core Carrier of Intelligent Control

3.1 Evolution of Power Device Energy Efficiency

Silicon carbide (SiC) MOSFETs are gradually replacing silicon-based IGBTs. Their wide bandgap characteristics support high-temperature operation above 200°C, reduce high-frequency switching losses by 50%, and significantly improve the efficiency of electric drive systems (increasing range by 3-5%). This technology has been applied to main drive inverters and on-board chargers (OBC). Although module packaging technology has made breakthroughs, SiC substrate epitaxial wafers remain highly dependent on the international supply chain, posing capacity risks.

3.2 Advances in Sensor Chip Technology

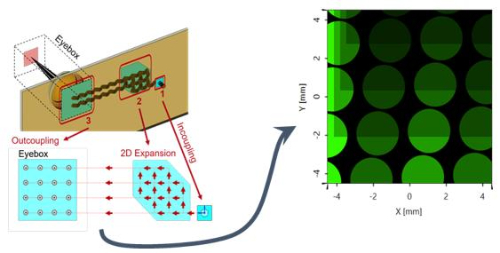

The LiDAR core uses direct time-of-flight (dToF) technology and includes two solutions: pulse ranging and single-photon avalanche diode (SPAD) arrays. The integrated receiver kit (APD+TIA+ToF chip) can achieve ±10mm ranging accuracy and 10ns-level overload recovery. Multi-zone sensors (such as a 64-pixel array) support 285cm ranging with strong light interference resistance, enabling in-vehicle gesture recognition and occupant monitoring systems.

Fig. 5 SPAD and SPAD arrays: From Single-Photon Detection to System-Level Imaging Platforms

3.3 Computational Control Chip Architecture

Intelligent cockpits and autonomous driving domain controllers are dominated by high-performance chips (such as Qualcomm/NVIDIA solutions). Automotive-grade microcontrollers (MCUs) must pass ISO 26262 ASIL-D functional safety certification, with development thresholds focused on controlling fault rates (<10 FIT) and ensuring real-time response delays (<50 μs).

4 Laser Ranging Technology: Precision Implementation of Environmental Perception

4.1 Comparison of Technical Approaches

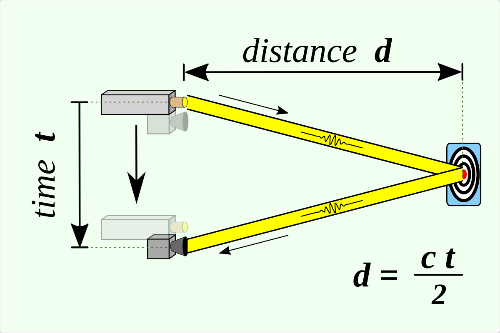

dToF (direct time of flight): Calculates distance (d=c·Δt/2) by measuring the round-trip delay (Δt) of laser pulses, with millimetre-level accuracy, kilometre-level range, and strong anti-interference capabilities.

iToF (indirect time of flight): Relies on the phase difference between the transmitted and received waveforms, is relatively low in cost, but is susceptible to interference from ambient light (error >40% in strong light).

Fig. 6 Schematic Diagram of Laser Pulse Ranging

4.2 dToF Core Device Architecture

The transmitter end of the direct time-of-flight (dToF) system uses a 940 nm vertical-cavity surface-emitting laser (VCSEL), which complies with the IEC 60825-1 eye safety standard while maintaining power consumption below 2 W. The receiver consists of an avalanche photodiode (APD), transimpedance amplifier (TIA), and time-to-digital converter (TDC) working in tandem: the APD achieves a photoconductive response rate of >50 A/W at the 905 nm wavelength, the TIA provides a bandwidth of 290 MHz and ensures a signal recovery time of <10 ns, and the TDC achieves a time resolution of 20 ps for precise ranging. The optical system employs diffractive optical elements (DOE) for multi-region beam control, with typical applications such as a 64-zone scanning architecture, providing the foundation for spatial resolution detection.

Fig. 7 VCSEL System

4.3 Application Scenario Performance Boundaries

In short-range high-precision scenarios (such as automatic parking systems), dToF technology can achieve positioning accuracy of ±1 cm within a range of <10 metres, but requires algorithmic suppression of multipath interference caused by ground reflections. For long-range dynamic detection (such as high-speed ADAS), reliable ranging beyond 200 metres relies on the combination of high-peak-power pulse laser emitters and multi-megapixel single-photon avalanche diode (SPAD) arrays to overcome atmospheric attenuation and signal-to-noise ratio degradation caused by moving targets.

5 Industrial Collaboration Framework: Multi-Material Integration Drives System Development

The technological evolution of new energy vehicles relies on the deep integration of battery energy storage systems, semiconductor control units, and laser sensing devices across multiple physical fields. At the energy flow level, silicon carbide (SiC) power modules reduce switching losses by 50%, enabling 800V high-voltage platforms to support 4C-rate solid-state battery fast charging while reducing the load on thermal management systems; Information flow coordination involves real-time processing of lidar (dToF) point cloud data by a domain controller (with over 100 TOPS computing power), dynamically adjusting battery output power (with a response delay of less than 100 ms) to achieve optimal torque efficiency allocation; Safety flow coordination is achieved by fusing battery pack multi-sensor data (temperature/voltage/deformation) with laser obstacle detection data, triggering SiC devices to shut down within 2 microseconds to prevent thermal runaway propagation.

5.1 Core Component-Level Collaboration Case Study

The ultra-fast charging safety protection chain demonstrates a typical interaction: a 480kW ultra-fast charging station outputs 800V high voltage to the SiC on-board charger (OBC), driving the solid-state battery to charge at a 4C rate. When the battery temperature gradient exceeds 5°C, the thermal management chip generates a PWM signal to activate the cooling pump, while a vertical-cavity surface-emitting laser (VCSEL) simultaneously monitors temperature with ±0.1°C precision, forming a three-tier protection system of "laser monitoring-BMS dynamic current limiting-SiC shutdown." The adaptive cruise control scenario highlights energy efficiency optimisation: The lidar detects the distance to the vehicle ahead within ±10 cm accuracy up to 200 metres, the domain controller (128 TOPS computing power) calculates the required torque, the power chip adjusts the switching frequency (16 kHz to 50 kHz), and the battery system outputs 30–150 kW of power as needed (with SOC fluctuation <1% per kilometre). This collaborative chain has been validated to increase range by 12% under WLTC conditions.

5.2 Challenges and Breakthroughs in Material Interface Interaction

Electromagnetic interference (EMI) between batteries and semiconductors affects the accuracy of battery management systems. The use of nanocrystalline shielding films can achieve over 30 dB attenuation. The thermal noise issue of laser ToF chips is addressed by cooling the germanium-silicon (SiGe) substrate by 50°C to improve the signal-to-noise ratio. Optical shifts caused by battery vibrations are resolved using active alignment algorithms (with compensation accuracy of ±0.05°). The Boston Consulting Group model indicates that such collaborative technologies could reduce the cost of the entire vehicle by 18% by 2030, with value derived from a 40% increase in battery reuse value, a 15% improvement in semiconductor energy efficiency for extended range, and a reduction in lidar costs to £500 per unit through systemic gains.

6 Conclusion

The development of new energy vehicles has transitioned from individual technological innovations to a stage of systematic collaboration among batteries, semiconductors, and laser materials. These three elements form a closed-loop technological ecosystem through deep interaction in energy, information, and safety flows.

In the energy dimension, silicon carbide power modules reduce switching losses by 50%, enabling the 800V platform to achieve 4C-rate fast charging while simultaneously reducing battery thermal management loads; in the information dimension, lidar point cloud data is processed in real-time by the domain controller (with latency <100ms), dynamically optimising battery power output and torque distribution; On the safety dimension, a multi-sensor fusion mechanism triggers semiconductor devices to shut down within 2 microseconds to prevent thermal runaway propagation.

This collaboration yields significant cross-domain benefits: improved semiconductor efficiency extends range by 12% (under WLTC conditions), lidar costs are reduced to £500 per unit, battery reuse value increases by 40%, and the system drives an 18% reduction in vehicle costs by 2030. Future breakthroughs will focus on interface-collaborative transmission between all-solid-state batteries and wide-bandgap semiconductors (GaN-on-SiC), integrated sensing and computing on photonic chips, and the development of AI-driven superlenses (diffraction efficiency exceeding 90%) and electromagnetic shielding materials (attenuation exceeding 50 dB). Only by breaking down the disciplinary barriers between materials science, optoelectronics, and electrochemistry can the next-generation intelligent vehicle achieve a technological paradigm shift characterised by "intrinsic safety, ultra-high efficiency, and sustainable recycling."

Stanford Advanced Materials proudly supports industry leaders with its comprehensive portfolio of these materials tailored for batteries, semiconductors, and laser technologies. We invite researchers and manufacturers to collaborate with us and leverage our expertise to drive the future of intelligent, efficient, and sustainable new energy vehicles.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento