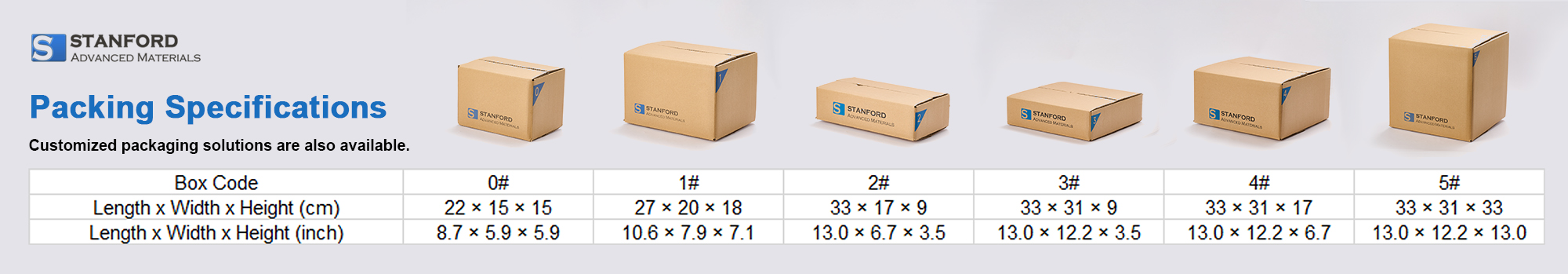

Please contact us for any additional questions or customized packaging needs.

Packaging Solutions

Company Introduction

Founded in 1997 and headquartered in California, USA, Stanford Advanced Materials (SAM) is a global supplier specializing in high-performance materials. With dedicated operations across the United States, Europe, and Asia, we serve clients in sectors including electronics, energy, aerospace, and precision manufacturing. Our core product lines include ceramics, permanent magnets, rare earth elements, precious metals, 3D printing powders, and crystal materials.

Packaging Materials Overview

To ensure materials arrive in compliance with performance and safety expectations, all SAM shipments are prepared using verified packaging methods and QA-inspected containers. Common packaging types include:

-

High-Strength Corrugated Cartons

Available in multiple dimensions. Compression-rated for durability and recyclable under RoHS-compliant processes. -

Square Fiberboard Drums

Designed for high-mass or bulk items requiring structural rigidity and internal protection. -

Steel Drums and Wooden Crates

Used for shipments exceeding 20 kg, offering external protection against load-bearing stress, vibration, and stacking impact.

All packaging types are sealed using the H-taping method and reinforced with cross-pattern strapping. Batch-level traceability is logged during sealing.

Packaging Operation Procedures

All packaging follows controlled procedures designed for consistency, accountability, and customer assurance.

1. Packing Area Preparation

-

Clean the packing area to ensure no cross-contamination from previous tasks.

2. Pre-Packing Verification

-

Identify the business line and packaging requirements from the green reference label.

-

Use business-provided labels and handle each item individually.

-

Select packaging based on weight, geometry, and risk profile.

-

Apply cushioning as required.

-

Log order number, packed quantity, and packaging method in the batch packing record.

3. QC Checkpoint (Pre-Sealing)

-

Inspect workspace to confirm no unprocessed items remain.

-

Notify the business team for visual and count verification.

-

QC inspects internal packaging for structural fit and damage resistance.

4. Sealing and External Validation

-

External labels are affixed by the business team.

-

QC verifies labeling accuracy and external strapping consistency.

5. Completion

-

Transfer packaged goods to the shipping zone.

-

Reset and clean workstation for the next order.

Packaging Box Specifications and Sealing Requirements

|

Box Code |

External Dimensions (cm) |

External Dimensions (in) |

|

0# |

22 × 15 × 15 |

8.7 × 5.9 × 5.9 |

|

1# |

27 × 20 × 18 |

10.6 × 7.9 × 7.1 |

|

2# |

33 × 17 × 9 |

13.0 × 6.7 × 3.5 |

|

3# |

33 × 31 × 9 |

13.0 × 12.2 × 3.5 |

|

4# |

33 × 31 × 17 |

13.0 × 12.2 × 6.7 |

|

5# |

33 × 31 × 33 |

13.0 × 12.2 × 13.0 |

|

6# |

35 × 35 × 39 |

13.8 × 13.8 × 15.4 |

|

Square Fiberboard Drum |

37 × 37 × 36 |

14.6 × 14.6 × 14.2 |

Need to convert other dimensions? Use our Length Unit Converter.

-

Cartons are sealed using the H taping method.

-

Shipments over 20 kg must use steel drums, fiberboard drums, or wooden crates.

-

Square fiberboard drums are sealed with tape and reinforced with cross-shaped strapping.

-

Round drums are additionally boxed with fiberboard cartons and secured with cross-shaped strapping.

Packaging Methods by Product Type

-

Large Cargo

Use steel drums or wooden crates. QC ensures stacking resistance and impact absorption. -

Small Cargo

Use weight-rated cartons with interior bracing. Label verification and cushioning required. -

Irregular-Shaped Items

Customized inner supports or molded inserts are required. Final fit is reviewed by QC for pressure distribution.

Packaging Compliance and Guarantee

-

All packaging follows SAM's internal QA protocol and relevant environmental directives.

-

Deformed, outdated, or non-rated packaging components are not permitted.

-

Product traceability via label codes and shipment logs is mandatory.

-

SAM guarantees packaging integrity and will provide compensation or corrective actions for failures due to packaging deviation.

Durability & Environmental Commitment

SAM uses packaging materials that are both high-performance and environmentally responsible. All cartons and drums meet transport durability standards without requiring destructive drop testing. Packaging is selected based on material type, risk category, and storage duration.

Frequently Asked Questions (FAQs)

-

Q: Can your packaging ensure product safety during transport?

A: Yes. All packaging is QC-verified and designed to meet impact, vibration, and stacking load requirements for long-haul shipping. -

Q: What if products are damaged during transit?

A: We trace all failures to batch logs and take full responsibility for packaging-induced damage. Resolution is initiated within 24 hours. -

Q: How do you select packaging per item?

A: Based on product weight, geometry, and handling sensitivity. QC oversees final selection and validation. -

Q: Do you label all boxes with traceable info?

A: Yes. Every box is labeled with product code, batch number, and company branding. -

Q: Are packaging materials compliant and recyclable?

A: Yes. All materials meet current EU and US environmental packaging standards.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Rachel Monroe

Rachel Monroe