Tantalum Products in Electronics

The global demand for tantalum in electronics is anticipated to grow at a CAGR of 6.2% until 2028, driven by 5G infrastructure, electric vehicles (EVs), and miniaturised medical devices. The unique combination of electrical performance, thermal stability, and corrosion resistance of tantalum renders it essential for several electronic applications. Although tantalum represents a minor portion of the overall raw material volume in electronics, its strategic importance remains significant, particularly where performance, size, and durability are critical.

Typical Tantalum Product Forms in Electronics

1. Tantalum Capacitors

Tantalum capacitors account for the largest individual application of tantalum metal, representing approximately 60–70% of total supply. Tantalum capacitors utilise sintered tantalum powder as a porous anode and tantalum pentoxide (Ta₂O₅) as a dielectric coating. Conductive polymers or manganese dioxide function as cathodes.

Tantalum capacitors provide several crucial advantages. They exhibit high volumetric efficiency, offering substantially greater capacitance per unit volume compared to other capacitor types, such as ceramic or aluminium capacitors. Additionally, they demonstrate excellent thermal and frequency stability, maintaining consistent performance across a wide temperature range and varying signal frequencies. Tantalum capacitors are noted for their extended lifespan and reliability, rendering them suitable for use in harsh environments and applications demanding high reliability.

Applications include:

- Consumer electronics such as smartphones, tablets, and laptops

- Implantable medical devices like pacemakers and neurostimulators

- Automotive electronic control units (ECUs) and infotainment systems

- Aerospace and defence avionics where performance and durability are critical

Further reading: Tantalum Pentoxide in Electronics: A Key Ingredient for Miniaturisation

2. Tantalum Thin Films in Semiconductors

In the semiconductor sector, tantalum and tantalum nitride (TaN) serve as diffusion barriers and adhesion layers for copper interconnects in high-performance integrated circuits (ICs). They are deposited as thin films using physical vapour deposition (PVD) or atomic layer deposition (ALD) techniques.

Tantalum and tantalum nitride (TaN) fulfil significant roles in semiconductor devices. Firstly, they provide effective barrier protection by hindering copper atoms from diffusing into adjacent silicon or dielectric layers, which could detract from device performance. Secondly, they enhance structural reliability by improving resistance to electromigration and maintaining mechanical integrity, particularly as interconnect dimensions continue to decrease. Lastly, they facilitate strong interlayer adhesion, essential for supporting intricate 3D packaging structures.

Tantalum Thin Films are employed in:

- Central processing units (CPUs), graphics processing units (GPUs), and system-on-chip (SoC) devices

- DRAM and NAND flash memory

- Advanced packaging technologies such as through-silicon vias (TSVs), 2.5D, and 3D integrated circuits

3. Tantalum Nitride Resistors

Tantalum nitride (TaN) is used in thin-film resistors due to its enhanced heat and moisture resistance, making it more reliable than chromium-based films in harsh environmental conditions. These resistors provide stable resistance over time and temperature, low noise suitable for analog circuits, and high accuracy with tight tolerance levels.

Tantalum Nitride Resistors are applied in:

- High-accuracy analog and sensor circuits

- Aerospace and military electronics where predictable performance is critical

- Medical instrumentation demanding stable electrical response to physiological conditions

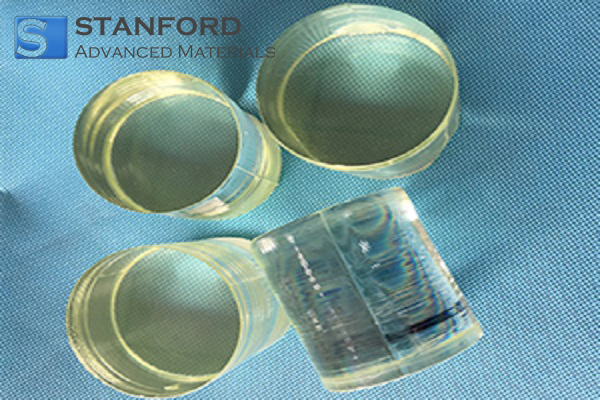

4. Lithium Tantalate Crystals

Lithium Tantalate (LiTaO₃) is a ferroelectric and piezoelectric material widely used in Surface Acoustic Wave (SAW) and Bulk Acoustic Wave (BAW) filters—key components in RF signal processing.

These devices find application in:

- Smartphones and mobile communication systems (4G, 5G)

- GPS modules and wireless communication devices

- Radar systems and satellite communication platforms

As wireless technologies progress to higher frequencies and broader bandwidth, the need for high-performance RF filters constructed from lithium tantalate is increasing.

Summary Table: Types and Applications of Tantalum Products in Electronics

|

Tantalum Product |

Function |

Key Advantages |

Typical Applications |

|

Tantalum Capacitors |

Store electrical charge in a compact form |

• High volumetric efficiency • Excellent thermal/frequency stability • Long operational lifespan |

• Smartphones, tablets, laptops • Medical implants (pacemakers, neurostimulators) • Automotive ECUs and infotainment • Aerospace and military avionics |

|

Tantalum Thin Films (Ta/TaN) |

Barrier and adhesion layers in copper interconnects |

• Prevent copper diffusion • Enhance electromigration resistance • Support advanced 3D packaging |

• CPUs, GPUs, SoCs • DRAM, NAND flash • TSVs, 2.5D/3D IC packaging |

|

Tantalum Nitride Resistors |

Provide precise resistance in circuits |

• High thermal and moisture resistance • Low noise • Tight tolerance precision |

• Analog and sensor circuits • Aerospace and defence electronics • Medical instrumentation |

|

Lithium Tantalate Crystals |

Enable RF signal filtering (SAW/BAW filters) |

• High frequency performance • Low insertion loss • Excellent temperature stability |

• Mobile phones (4G/5G) • GPS and wireless modules • Radar and satellite communications |

For further tantalum products, please consult Stanford Advanced Materials (SAM).

Market Drivers and Emerging Trends

Several convergent trends are promoting the expansion of tantalum applications in electronics:

- 5G Networks: The deployment of 5G networks has heightened the requirement for stable RF filters and high-density capacitors that can accommodate high data transmission rates and signal density.

- Electric Vehicles (EVs): Tantalum capacitors are employed in EV power management systems, battery monitoring circuits, and advanced driver-assistance systems (ADAS) due to their stability under high current loads.

- Medical Electronics: Implantable and wearable devices necessitate miniaturised, biocompatible, and long-lasting components—attributes that tantalum capacitors and resistors are capable of providing.

- Aerospace and Defence: Tantalum components are preferred in defence electronics because of their radiation hardness, mechanical strength, and stable operation across broad temperature ranges.

Conclusion

From capacitors with high power density to sophisticated semiconductors and RF filters, tantalum is integral in enhancing the performance, compactness, and reliability of modern electronics. As industries transition towards higher frequencies, smaller form factors, and greater reliability, the significance of tantalum in electronics is expected to intensify.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento