6 Common Coating Methods For Non-Ferrous Metals

Introduction

Non-ferrous metals, including aluminium, copper, zinc and titanium, are valued for their distinct properties such as low weight, high conductivity and excellent corrosion resistance. To improve these properties and extend the service life of non-ferrous metals, various types of coatings are applied. These coatings provide extra protection against environmental influences, enhance the aesthetic appearance and improve the surface properties. This guide explains the common types of coatings for non-ferrous metals and details their advantages with concrete examples.

1. Anodising

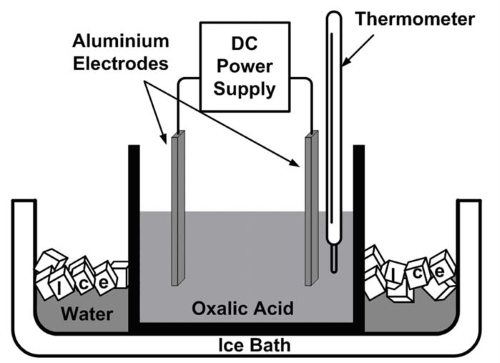

Anodising is an electrochemical process primarily used for aluminium and its alloys. In this method, the aluminium is immersed in an electrolytic solution where it acts as the anode. When an electric current runs through the solution, oxygen ions are released from the electrolyte and combine with aluminium atoms on the surface, thereby forming a thick, corrosion-resistant oxide layer.

[1]

[1]

Advantages of anodising:

- Corrosion resistance: The anodic oxide layer is highly resistant to corrosion and is suitable for outdoor applications and harsh environments.

- Increased surface hardness: Anodising raises the surface hardness of aluminium and improves its resistance to wear.

- Aesthetic options: The porous nature of the anodised layer allows for dyeing, which results in a wide range of colour options.

- Thermal insulation: The anodised layer provides thermal insulation, meeting the demands of heat-resistant applications.

In consumer electronics, anodising is frequently applied to aluminium casings for smartphones, laptops and tablets. The process yields a smooth and durable surface and improves scratch resistance, thereby maintaining the device’s appearance over time.

2. Electroplating

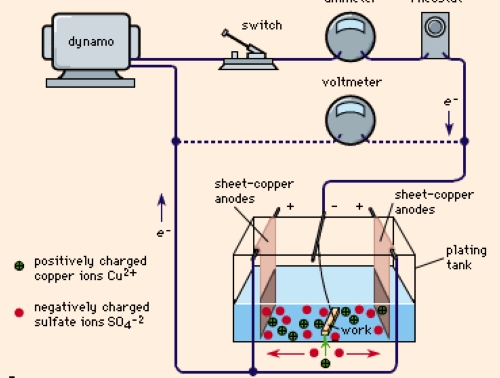

Electroplating uses an electrochemical process to deposit a thin metal layer onto the surface of another metal. Commonly used coating metals include nickel, chromium, copper and gold. In this process, the workpiece (cathode) and a metal to be deposited (anode) are immersed in an electrolytic solution. An electric current is then applied, which causes the coating metal to dissolve and deposit onto the cathode.

Advantages of electroplating:

- Improved external finish: Electroplating achieves a glossy and attractive surface that enhances the metal’s appearance.

- Enhanced corrosion resistance: The deposited layer provides additional protection against corrosion and oxidation.

- Better surface properties: The coating improves surface conductivity, hardness and wear resistance, which is beneficial for electrical components and decorative items.

- Reduced friction: Certain plating materials can lower friction, which is advantageous for mechanical parts.

In the jewellery industry, gold and silver electroplating is used for base metals such as copper and brass. This process allows the production of cost-effective jewellery that retains its appearance and resists tarnishing.

3. Powder Coating

Powder coating is a dry finishing process that is frequently employed for aluminium, magnesium and other non-ferrous metals. In this process, a dry powder, typically composed of a thermoplastic or thermoset polymer, is applied electrostatically onto the metal surface. The coated metal is then heated so that the powder melts and forms a hard, even surface.

Advantages of powder coating:

- Durability: Powder-coated surfaces are thick and resistant to chipping, scratching and fading.

- Corrosion resistance: The coating provides excellent protection against corrosion, making it suitable for outdoor and marine applications.

- Environmental benefit: Compared to conventional liquid paints, powder coating produces only minimal volatile organic compounds (VOC).

- Diverse finishes: The process is available in a broad range of colours and textures, offering many design options.

Powder coating is widely used in the automotive industry for parts such as wheels, frames and suspension components. The coating withstands the demands of road use while maintaining an attractive finish.

4. CVD and PVD

Chemical Vapour Deposition (CVD) and Physical Vapour Deposition (PVD) are advanced coating processes that deposit thin layers from various materials onto non-ferrous metals. In CVD, chemical reactions occur in the vapour phase. In contrast, PVD deposits the material physically from the vapour phase.

Advantages of CVD and PVD:

- High coating quality: Both methods yield uniform coatings with excellent adhesion.

- Improved surface characteristics: The coatings enhance hardness, wear resistance and corrosion protection.

- Versatility: CVD and PVD allow a wide selection of materials, including metals, ceramics and polymers, to be deposited.

- Precise control: These methods enable precise management of coating thickness and composition.

In the aerospace industry, CVD and PVD are applied to turbine blades and other components. This improves performance and durability under extreme operating conditions.

5. Passivation

Passivation is a chemical treatment that improves the corrosion resistance of stainless steel, titanium and other alloys. In this method, free iron is removed from the metal surface and a thin, inert oxide layer is formed. This layer serves as a barrier that prevents further oxidation and corrosion.

Advantages of passivation:

- Enhanced corrosion resistance: The passivation layer significantly increases the metal’s resistance to corrosion.

- Clean surface: The process removes contaminants, resulting in a clean metal surface.

- Preservation of appearance: Passivation helps maintain the natural appearance of the metal and prevents tarnishing.

- Extended lifespan: By reducing corrosion, passivation prolongs the functional life of metal components.

For instance, passivation is crucial for stainless steel medical devices such as surgical instruments and implants. It ensures that these devices remain corrosion-free and retain their biocompatibility.

6. Organic Coatings

Organic coatings include paints, varnishes and polymers that are applied to non-ferrous metals to provide protection and enhance their appearance. These coatings form a barrier that shields the metal from environmental factors such as moisture, chemicals and UV radiation.

Advantages of organic coatings:

- Versatility: Organic coatings are available in various formulations, colours and finishes, providing flexibility in design.

- Corrosion protection: They offer effective protection against corrosion and environmental degradation.

- Ease of application: Organic coatings can be applied by spraying, brushing or dipping.

- Cost effectiveness: These coatings are relatively inexpensive and provide a quick solution for protecting non-ferrous metals.

Organic coatings are commonly used in architecture for windows, doors and façades. They improve the outward appearance of buildings and protect the underlying metal from weathering and corrosion.

Conclusion

The selection of a coating for non-ferrous metals depends on specific requirements such as the required corrosion resistance, appearance and surface properties. By choosing the appropriate coating, manufacturers may improve the performance, durability and lifespan of non-ferrous metal components. This ensures that the components meet the demands of various industries and environments. We trust that you will find the suitably coated products at Stanford Advanced Materials (SAM).

Referencing:

[1] Ahmad, Hafiz Imran; Sharif, Muhammad; Hussain, Safdar; Badar, M.; Afzal, H. (2013). Spectroscopic Study of a Radio-Frequency Atmospheric Pressure Dielectric Barrier Discharge with Anodic Alumina as the Dielectric. Plasma Science and Technology, 15, 900. DOI:10.1088/1009-0630/15/9/13.

[2] Galvanotechnik. (16/05/2024). In Britannica. https://www.britannica.com/technology/electroplating

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento