Military Tungsten Alloy Counterweight

The military tungsten alloy counterweight exhibits a high density, high hardness, high tensile strength, wear resistance, impact resistance, high‐temperature resistance, corrosion resistance, ease of processing, resistance to radiation and measurable creep resistance. It is also environmentally friendly and non‐toxic.

Military counterweight made of tungsten alloy

Compared to many similar counterweights, the advantage of the military counterweight made from tungsten alloy is its high mass-to-volume ratio; consequently, a higher specific weight is achieved in a smaller volume. It is therefore suited for applications where space is limited. For example, it may be applied as a core filler for armour-piercing projectiles or as a counterweight for heavy armament, thereby reducing recoil.

Advantages of Military Tungsten Alloy Counterweights

1. High Density

The tungsten alloy counterweight possesses a high specific gravity. Its density typically ranges between 16.5 and 19 g/cm³, which is more than twice that of conventional steel.

2. Adequate Machinability

Owing to its ductility, the tungsten alloy counterweight can be machined, milled, planed and threaded. It may also be subjected to deformation strengthening processes such as forging, thereby enabling production of components in various shapes.

3. Satisfactory Ductility

The mass-produced W-Ni-Fe alloy, a high-density tungsten alloy, exhibits an elongation of 10%–15% in its sintered state. After treatment by dehydrogenation in vacuum or controlled atmosphere, the elongation is increased to between 20% and 30%.

4. High Tensile Strength

The tensile strength of the sintered arch-shaped tungsten alloy counterweight is 800–1000 MPa; after heat treatment and deformation processing, its strength can reach between 1300 and 1500 MPa.

5. Good Thermal Conductivity and Low Linear Expansion

The thermal conductivity of the tungsten alloy counterweight is approximately five times that of steel, and its linear expansion coefficient is only between one-half and one-third of that of iron or steel.

Applications of Tungsten Alloy Counterweights

Tungsten alloy counterweights are used in several fields. In addition to military applications, they serve as mechanical counterweights, in oscillatory hammers, as ballast rods in the oil and drilling industries, in clock pendulums, in impact-resistant beam components, as counterweight spheres, in vibrators for mobile phones and game consoles, as ballast weights and counterweight components for navigation and sailing, and in gyroscopic systems as well as counterweights for aircraft in the aeronautics and space sectors.

Conclusion

Thank you for reading this article. We trust it assists in obtaining a clearer understanding of the military tungsten alloy counterweight. If further information regarding tungsten and tungsten alloys is required, please visit Stanford Advanced Materials (SAM) for additional data.

Stanford Advanced Materials (SAM) is a worldwide supplier of tungsten products. With over two decades of experience in manufacturing and distributing tungsten and tungsten alloys, the company provides products that satisfy the research and production requirements of its customers. As such, SAM is positioned to be your preferred supplier and business partner for tungsten products.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

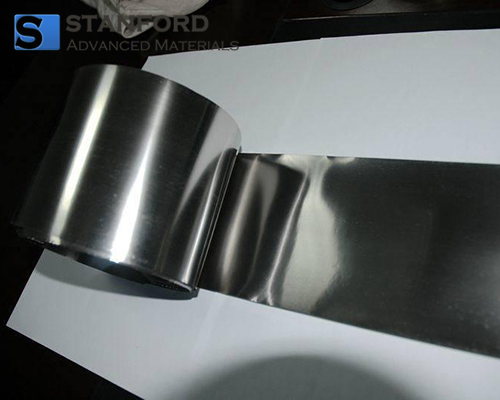

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento