Oxidation Processes And Oxidation Resistance

Introduction

Oxidation is likely the most basic of chemical reactions in nature and industry. At its core, it is a process by which a material loses electrons and often also experiences a phase change, physical or chemical. From rusting on steel bridges to controlled fuel oxidation in vehicles, oxidation produces various technologies and natural phenomena. Having some basic knowledge of oxidation—and more crucially, how to suppress it or regulate it—is required when designing materials capable of withstanding tough environments.

How It Works

Chemical oxidation rarely occurs alone. It occurs simultaneously with reduction in a redox reaction. An element loses electrons (oxidation), and another element gains electrons (reduction). For example:

[Fe + O2 → Fe2O3]

Iron (Fe) loses electrons to oxygen to form iron oxide—commonly known as rust.

Redox reactions power important processes in industrial and biological systems:

• Metallurgy: Reduction and oxidation under controlled conditions are relied on for smelting and refining metals.

• Power generation: Batteries and fuel cells convert redox reactions to useful electrical energy.

• Biological systems: Glucose is oxidised in cellular respiration in order to produce ATP, the body's currency of energy.

Why Oxidation Resistance Is Important

While oxidation supports positive reactions, uncontrolled oxidation can be problematic for materials and systems. Metals exposed to air, water, or high temperatures gradually deteriorate because they react with oxygen, sulfur, or water vapour.

Oxidation resistance defines how resistant a material is to such conditions without degrading. It is especially crucial in:

• Aerospace: Jet turbine blades must resist oxidation above temperatures of 1,000°C.

• Transportation: Exhaust systems and catalytic converters rely on oxidation-resistant alloys to ensure long-term stability.

• Electronics and semiconductors: Coating sensitive devices with thin films to avoid exposure to oxygen.

• Energy and chemical processing: Reactors, pipelines, and heat exchangers require materials that are unaffected by oxidising gases or liquids.

Examples of Oxidation-Resistant Materials

Some materials possess inherently high oxidation resistance due to the formation of stable, adherent oxide films to prevent further reaction.

• Stainless steel: Forms a self-repairing layer of chromium oxide (Cr₂O₃) that resists diffusion of oxygen.

• Titanium: Forms a thin TiO₂ layer, which is highly protective even at high temperatures.

• Ceramics (alumina or zirconia): Already stable in oxidative conditions, ideal for thermal barrier coatings.

• Nickel-based superalloys: Maintain protective oxide scales above 1,100°C, used in turbines and aircraft engines.

Examples of Oxidation-Resistant Metals

|

Metal / Alloy |

Mechanism of Resistance |

Typical Applications |

|

Chromium Alloys |

Form a dense, adherent Cr₂O₃ film |

Jet engines, heating elements |

|

Titanium Alloys |

Stable TiO₂ layer prevents further oxidation |

Aircraft parts, medical implants |

|

Nickel-Based Superalloys |

Develop protective Al₂O₃ or Cr₂O₃ scales |

Gas turbines, rocket engines |

|

Aluminum Alloys |

Natural Al₂O₃ coating forms instantly in air |

Automotive panels, aerospace frames |

|

Silicon Carbide (SiC) |

Forms SiO₂ layer that resists oxidation |

Furnace components, high-temperature coatings |

Factors Influencing Oxidation Resistance

Oxidation resistance of a material is determined by numerous factors, which influence each other:

1. Composition of the Material:

Chromium, aluminium, and silicon elements enhance resistance through the development of stable oxides.

Stainless steel with >12% Cr has good air oxidation resistance.

2. Temperature:

The oxidation rate increases exponentially with temperature.

Oxidation at 800°C can be ten times higher than oxidation at 400°C.

3. Environment:

Moisture, sulfur compounds, and halogens can activate oxidation and disrupt protective oxide films.

4. Condition of Surface:

Smooth, clean surfaces allow easier formation of protective oxide films.

Rough, dirty surfaces can oxidise abnormally.

5. Protection Layers:

Physical layers of metal platings, ceramic coatings, or paints shield against corrosive agents and oxygen.

General Methods of Enhancement of Oxidation Resistance

Oxidation resistance can be increased by the choice of appropriate material and protective methods. Techniques include alloying, surface treatments, and protective coatings to increase the durability of material under oxidative conditions.

|

Method |

Description |

Applications |

|

Alloying |

Adding elements like chromium or aluminium |

Stainless steel, superalloys |

|

Protective Coatings |

Applying paints, platings, or thermal barriers |

Automotive parts, turbines |

|

Surface Treatments |

Techniques like anodising or carburising |

Aerospace components, tools |

For more information, please check Stanford Advanced Materials (SAM).

Frequently Asked Questions

What is oxidation in simple words?

Oxidation is a chemical process where a material loses electrons, typically reacting with oxygen and producing oxides.

Why is oxidation resistance important?

It refers to how well a material can resist oxidative or high-temperature environments without loss of strength or functionality.

Which metals have high oxidation resistance?

Chromium-, nickel-, and titanium-base alloys, as well as aluminium and silicon-containing materials.

Is it possible to improve oxidation resistance without changing the composition of the alloy?

Yes. Techniques like anodising, coating, or polishing of the surface can greatly enhance oxidation protection.

How does temperature affect oxidation?

A 100°C increase in temperature can roughly double the oxidation rate; therefore, high-temperature protection is extremely important.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

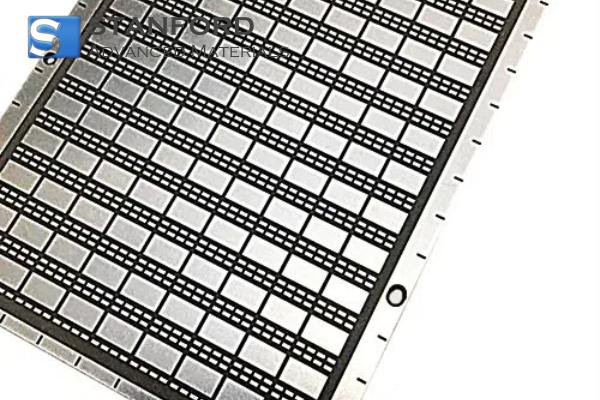

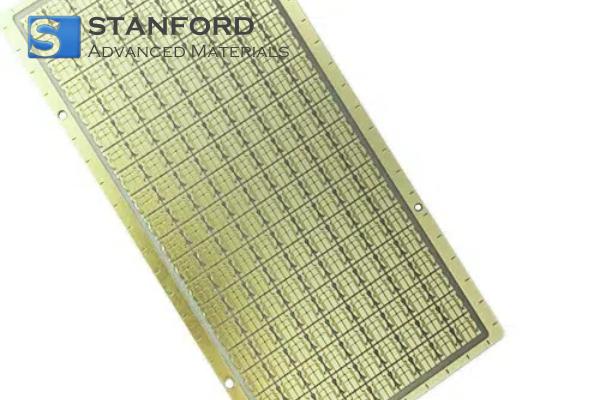

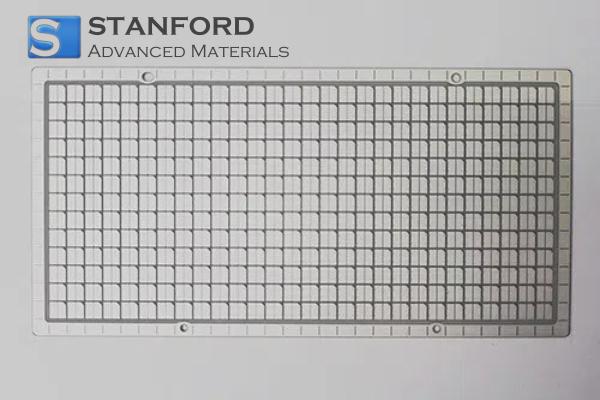

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento