Titanium: Element Properties And Uses

Description

Titanium is a strong, lightweight and corrosion‐resistant metal. Its long lifespan and versatility in challenging environments lead to its use in many sectors.

Introduction to the Element

Titanium (Ti), with atomic number 22, is a transition metal known for its high strength-to-weight ratio, corrosion resistance and high melting point. It occurs naturally in the Earth's crust, mainly in the minerals rutile and ilmenite. It is used for applications where strength, low density and corrosion resistance are essential, for example in the aerospace sector, in medical devices and in military equipment.

Chemical Properties Description

Titanium is a reactive metal that, at elevated temperatures, forms a thin and stable oxide layer on its surface. This layer protects it from further oxidation and corrosion. The oxide layer gives titanium its resistance to rust or other forms of deterioration, even in environments such as sea water and acidic solutions. Titanium reacts with halogens such as fluorine and chlorine to form titanium halides. It forms strong bonds with carbon, nitrogen and hydrogen, thereby producing compounds that are useful in alloy applications. Its ability to withstand high temperatures without degradation makes it suitable for precise technical tasks.

Titanium displays a capacity to maintain its composition at high temperatures. The material meets standard requirements for demanding engineering applications.

Table with Data on Physical Properties

|

Property |

Value |

|

Atomic Number |

22 |

|

Density |

4,54 g/cm³ |

|

Melting Point |

1 668°C (3 034°F) |

|

Boiling Point |

3 287°C (5 949°F) |

|

Tensile Strength |

434 MPa |

|

Elastic Modulus |

116 GPa |

|

Thermal Conductivity |

21,9 W/m-K |

|

Electrical Resistivity |

4,2 × 10⁻⁷ Ω-m |

|

Colour |

Metallic white |

Titanium's low density compared with other metals, such as steel, makes it appropriate for applications where an equilibrium between lightness and strength is required. Its high melting point and resistance to wear and corrosion enhance its value in the aerospace and industrial sectors. Further details are available at Stanford Advanced Materials (SAM).

Common Applications

Titanium is used in many sectors owing to its combination of strength, light weight and corrosion resistance. Some common applications are:

- Aerospace: Titanium is employed for the construction of aircraft frameworks, jet engines and spacecraft because of its strength-to-weight ratio and high-temperature resistance.

- Medical: Titanium is biocompatible. It is used for implants, prostheses and surgical instruments.

- Maritime: Titanium's resistance to corrosion makes it suitable for the construction of boats, submarines and other watercraft.

- Automotive: In the automotive sector, titanium is used for performance components, such as engine parts and exhaust systems.

- Sporting Equipment: Titanium is used in the production of lightweight and durable sporting goods such as golf clubs, bicycles and tennis racquets.

Processing Methods

Titanium is typically extracted from its ores, chiefly rutile (TiO₂) and ilmenite (FeTiO₃), via the Kroll process. In this process titanium tetrachloride (TiCl₄) is reduced with magnesium in an inert atmosphere, thereby producing pure titanium. The Kroll process is expensive but effective in producing high-purity titanium for industrial applications.

An alternative method is the Hunter process, in which sodium is used as the reducing agent. This method is less common than the Kroll process.

Related Industrial Products

Titanium is incorporated in various alloys and products that are developed for specific applications. These include:

- Titanium Alloys: Alloys such as Ti-6Al-4V (which contains aluminium and vanadium) are used in the aerospace sector.

- Titanium Dioxide: Used as a white pigment in paints, coatings and plastics due to its opacity and brightness.

- Titanium Coatings: Applied to steel and other metals to increase corrosion resistance, particularly in maritime and chemical processing sectors.

Frequently Asked Questions

What are the primary advantages of titanium?

Titanium is valued for its strength-to-weight ratio, corrosion resistance, biocompatibility and its capacity to withstand high temperatures. It is suitable for aerospace, medical and maritime applications.

What is the primary method for the production of titanium?

Titanium is mainly produced via the Kroll process, in which titanium tetrachloride (TiCl₄) is reduced with magnesium. This method is the most common for manufacturing high-purity titanium.

Why is titanium used in medical implants?

Titanium is biocompatible. Its strength, durability and resistance to corrosion make it appropriate for implants such as hip prostheses and dental devices.

How does titanium resist corrosion?

Titanium forms a protective oxide layer on its surface. This prevents further oxidation. Consequently, titanium exhibits significant corrosion resistance even in aggressive environments such as sea water and acidic conditions.

In which sectors is titanium used?

Titanium is used in the aerospace, medical, maritime, automotive and sporting equipment sectors due to its low density, high strength and resistance to corrosion.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

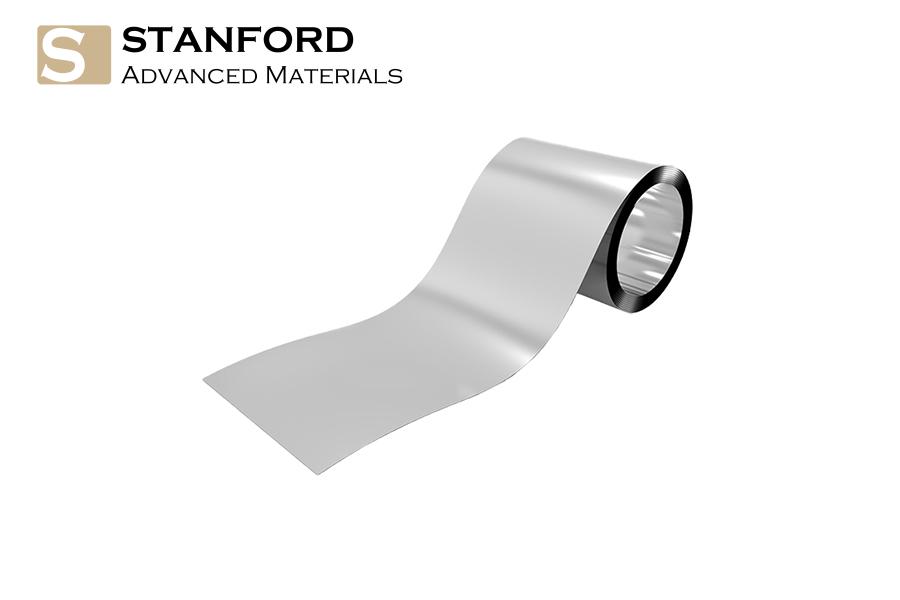

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento