An Overview Of The Nitinol

A Nickel-Titanium alloy, also known as Nitinol, is a binary alloy that is composed of Nickel and Titanium. The two elements are present in approximately equal atomic percentages (Nitinol 55 and Nitinol 60 are common).

Austenitic Phase and Martensitic Phase

Due to temperature fluctuations and mechanical stress, Nitinol exhibits two distinct crystal structure phases, namely the austenitic phase and the martensitic phase.

In Nitinol, the austenite is referred to as the parent phase. It is the crystal phase that the alloy exhibits at higher temperatures. When the temperature is reduced, the austenite gradually transforms into martensite (the secondary phase).

During the transformation of martensite to austenite, there are four types of temperatures:

* As: the temperature at which the transformation from martensite to austenite commences during a temperature increase.

* Af: the temperature at which the transformation from martensite to austenite is completed during a temperature increase.

* Ms: the temperature at which the transformation from austenite to martensite begins during a temperature decrease.

* Mf: the temperature at which the transformation from austenite to martensite is completed during a temperature decrease.

The phase transformation of Nitinol exhibits thermal hysteresis. Consequently, As is not equal to Mf, and for the same reason, Af is not equal to Ms.

Two Properties of Nitinol

1. Shape Memory

Shape memory occurs when the parent phase of a specific shape is cooled. The cooling occurs from a temperature above the Af temperature to a temperature below the Mf temperature. The cooling induces a complete transformation into martensite. The martensite is deformed below the Mf temperature.

After heating to a temperature below the Af temperature, the material automatically regains the form of the parent phase through phase reversion.

The shape memory effect is a thermally induced phase transition process in Nitinol. It refers to Nitinol's ability to be deformed at a certain temperature. The material can restore its original, undeformed shape once the temperature exceeds its transition temperature.

2. Superelasticity

Superelasticity refers to a phenomenon in which the specimen undergoes deformation beyond the elastic limit when external forces are applied. The deformation recovers automatically when the load is removed.

In the parent phase, the deformation induces a martensitic phase transition. This is due to the applied external stresses. The resulting mechanical behaviour differs from that of conventional materials.

Its elastic limit is significantly larger than that of conventional materials. Additionally, it does not obey Hooke's law. In contrast to the shape memory effect, no heat is required for superelasticity.

Applications of Nitinol

1. Eyeglass Frames

Although many applications of Nitinol are not visible to the general public, some are well known. Eyeglass frames made from Nitinol can be deformed significantly but revert to their original shape. A few years ago, mobile phones included retractable antennas. Many of these antennas were manufactured from Nitinol. This enabled them to bend without breaking or undergoing permanent deformation.

2. Orthodontics

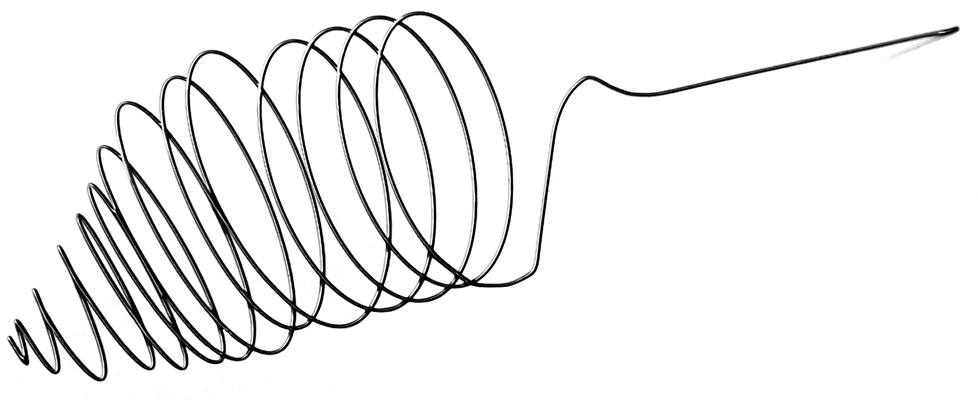

Another superelastic application, with which you or your children may have encountered, is in orthodontics. An orthodontist employs a Nitinol wire and shapes it to secure it to the teeth. Because the wire is superelastic, it attempts to return to its straight form, thereby applying a consistent force on the teeth. Consequently, the orthodontist needs to adjust the braces less frequently.

3. Medical Devices

Surgical instruments and components made from Nitinol meet numerous requirements, particularly in minimally invasive or arthroscopic surgery. They utilise the advantages of Nitinol's superelasticity and fatigue resistance. A curved tool can be straightened and introduced through a cannula, a rigid tube. After emerging from the cannula, the tool regains its original shape. The surgeon performs the procedure, and thereafter the tool is retracted into the cannula, where it realigns and can be easily removed.

Nitinol's superelastic property and its biocompatibility render it suitable for manufacturing various types of implanted medical devices. One application familiar to many is the stent, a device that supports blood vessels and keeps them open. Owing to Nitinol's superelasticity, a medical device such as a stent or a heart valve can be compressed into a shape that fits inside a catheter. The catheter is positioned at the appropriate location in the body, the device is released, and it regains its original shape.

Due to its superelasticity, Nitinol is the only material suitable for stents employed in the carotid artery or in the leg blood vessels. At these vulnerable sites, an impact on the area of a stent results in deformation. However, a Nitinol stent returns to its designed shape. Stents made of other materials would be crushed or permanently deformed under such impact.

4. Other Applications

A number of less well-known applications utilise the shape memory capability of Nitinol. A well-known computer manufacturer used a Nitinol device for ejecting PCMCIA cards (Personal Computer Memory Card International Association). Furthermore, Nitinol is employed in couplings that connect the ends of hydraulic hoses in aircraft. In a more recreational application, Nitinol permits the bending of spoons used in a magic shop when placed in hot water.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento