Capillary Tubes: Types And Applications

Capillary tubes are small, slender tubes with a narrow internal diameter that play a significant role in various scientific, industrial and medical applications. They are frequently employed in areas such as fluid mechanics, temperature measurement, chromatography and cooling. The following text examines their types, advantages and diverse applications.

What Are Capillary Tubes?

Capillary tubes are thin-walled tubes with an internal diameter ranging from a few micrometres to a few millimetres. Depending on the application, these tubes are typically manufactured from materials such as glass, stainless steel or plastic. The critical property is capillary action, a phenomenon whereby fluids rise in a narrow tube due to surface tension. Consequently, capillary tubes are useful in applications that require precise movement or measurement of small fluid quantities.

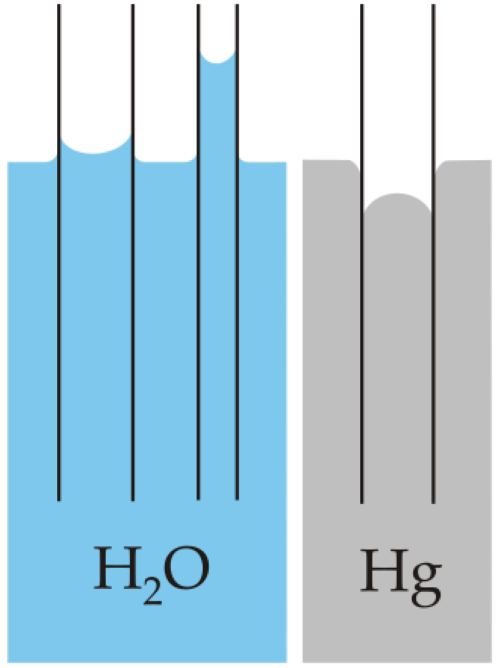

Capillary action arises from the interaction between the fluid and the inner surface of the tube. When the fluid is drawn into the confined space, it adheres to the tube walls while the surface tension counteracts gravity. Given that many devices depend on precise fluid flow, this effect plays an essential role in their operation. The diagram below illustrates capillary action and shows how a fluid with a polar surface, such as glass (≡Si-OH), interacts under these conditions.

[1]

[1]

Advantages and Applications

- Precision in Fluid Control: Capillary tubes facilitate the movement of fluids in measured quantities. They are well suited for applications in which fluid flow must be regulated accurately.

- No External Energy Required: They function on the basis of intrinsic physical forces such as surface tension and capillary action, thereby obviating the need for additional pumps or motors.

- Low Cost: These tubes are relatively inexpensive to produce, particularly when fabricated from glass. Their low production cost makes them an attractive option for many industries that demand precision without reliance on complex machinery.

- Compact Design: Their small dimensions make capillary tubes ideally suited for systems with limited space or for applications requiring only small volumes of fluid. Consequently, they can be easily incorporated into compact systems or devices.

- Versatility: Capillary tubes are available in various materials including glass, stainless steel and plastic, making them adaptable for use in diverse settings, including high-temperature or corrosive environments.

Materials Used in Capillary Tubes

Capillary tubes are available in different materials, sizes and configurations, each designed for specific applications. The most common types include:

1. Glass Capillary Tubes

Glass capillary tubes are the most frequently used type and are typically applied in laboratory settings. They are transparent, which allows for direct observation of the contained fluid. Their chemical inertness makes them appropriate for many chemical applications.

Applications: Used for temperature measurement, for instance in thermometers, and in laboratory experiments where fluid behaviour is monitored.

2. Stainless Steel Capillary Tubes

Capillary tubes constructed from stainless steel find application in more demanding industrial environments where durability and corrosion resistance are paramount. These tubes are suited for high-pressure systems or for use with aggressive chemicals. Their mechanical strength assists in handling pressurised fluids, particularly within systems that require measured precision.

Applications: Commonly used in cooling systems, hydraulic systems and medical devices.

3. Plastic Capillary Tubes

Plastic capillary tubes, manufactured from materials such as polycarbonate or Teflon, are lightweight and resistant to chemicals. They offer flexibility and can be moulded into various forms, which makes them suitable for applications where cost and weight are important considerations.

Applications: Employed in consumer goods, medical devices and various fluid management systems.

4. Bimetallic Capillary Tubes

Bimetallic capillary tubes are composed of two distinct metals bonded together. They are primarily used in temperature sensing applications. The differing rates of expansion of the two metals enable the tube to operate as a temperature-sensitive switch.

Applications: Widely utilised in thermostats and refrigeration systems for temperature regulation.

Applications of Capillary Tubes

Capillary tubes are employed in a variety of sectors ranging from scientific research to industrial processes. Some of the notable applications include:

1. Cooling Systems

In refrigeration technology, capillary tubes form an integral part of the expansion valve mechanism. The capillary regulates the flow of the refrigerant from the high-pressure side to the low-pressure side. As the refrigerant passes through the narrow tube, its pressure decreases, causing it to expand and cool, thereby producing a cooling effect. This application is standard in air conditioning systems and refrigeration units.

2. Thermometers

Capillary tubes are used in liquid-in-glass thermometers wherein the tube contains a fluid (typically mercury or alcohol) that expands or contracts in response to temperature variations. When the temperature increases, the fluid ascends within the tube, permitting precise measurement. Capillary tubes facilitate accurate readings even for minor temperature shifts.

3. Chromatography

In chromatography, capillary tubes are employed in both thin-layer chromatography (TLC) and gas chromatography (GC). These tubes utilise capillary action to move solvents through a stationary phase, thereby enabling the separation of components. This method is standard in chemical analysis to identify and quantify the constituents of a sample.

4. Fluid Flow Studies

Capillary tubes are frequently used in laboratory settings to examine fluid behaviour under controlled conditions. By measuring the ascent of a fluid in a capillary tube, researchers are able to determine properties such as surface tension and viscosity.

5. Medical Devices

In the medical field, capillary tubes are incorporated in devices such as blood collection tubes and capillary blood sampling instruments. Their small dimensions allow for the accurate extraction of minimal quantities of blood or other body fluids, which is essential for diagnostic tests. Additionally, capillary tubes are a component in certain types of medical thermometers.

6. Hydraulic Systems

Stainless steel capillary tubes are used in hydraulic systems to aid in controlling the flow of fluids under high pressures. They help maintain a consistent flow rate of oil or other fluids in machinery, thereby contributing to effective system operation.

7. Wicking and Fluid Movement

Capillary tubes are also applied in wick systems where they assist in the distribution of fluids across surfaces. This application is beneficial in industrial processes that involve liquid absorption and in devices such as ink pens, where capillary action facilitates the movement of ink to the nib.

Conclusion

Capillary tubes control the movement of fluids precisely without the need for external energy. They are valuable in cooling systems, temperature measurement, chromatography and medical devices. Stanford Advanced Materials (SAM) is capable of supplying capillary tubes of high purity at competitive prices, including those made from stainless steel, nickel-based alloys and precious metals. Whether for scientific, industrial or medical purposes, the capillary tubes from SAM are designed to meet the specific requirements of each client.

Stanford Advanced Materials (SAM) can provide capillary tubes that meet strict purity and performance criteria. Their products serve a wide range of applications in research and industry.

Reference:

[1] Kapillarwirkung. (30/12/2024). In Wikipedia. https://en.wikipedia.org/wiki/Capillary_action#

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento