How Is Tungsten Trioxide Used In Cobalt-Free Batteries?

One of the current topics is cobalt‐free batteries, which can be viewed as an improved version of commercial ternary lithium batteries. Given that these batteries offer higher energy density and lower production costs, many battery manufacturers favour them. How is Wolframtrioxid, a typical n‐type semiconductor material derived from a transition metal, employed in cobalt‐free batteries?

How is Wolframtrioxid used in cobalt‐free batteries?

Ultra‐fine Wolframtrioxidpulver can be used both as a modifying agent for cobalt‐free battery cathode materials and in the fabrication of high‐performance anode materials.

In cathode materials, the use of Wolframtrioxid powder reduces the quantity of cobalt metal and increases the specific capacity and thermal stability of the product. In negative electrode materials, it improves the rate performance and the lithium storage kinetics.

It is well known that the major cost in new energy vehicles arises from the power batteries. In the market‐dominant ternary lithium battery, cobalt is a key rare metal. Its occurrence is limited and production levels are low, thereby keeping cobalt prices high relative to other rare metals. Consequently, this raises the production costs of power batteries.

In February 2020, Tesla proposed the concept of cobalt‐free batteries, thereby placing the removal of cobalt at the forefront. Consequently, various cobalt‐free solutions have gradually been introduced by energy battery manufacturers.

Given their distinct physical and chemical properties, tungsten trioxide nanoparticles are often used as a substitute for cobalt in lithium‐ion batteries. Tungsten oxide possesses a larger specific surface area, a higher specific weight and good mechanical stability. This improves the specific energy capacity and thermal stability of the cathode materials. It also reduces the likelihood of thermochemical reactions between the positive electrode material and the electrolyte. This reduction lowers the possibility of a rise in partial pressure and temperature within the battery.

To further improve capacity and charge/discharge rates, researchers have proposed the use of tungsten trioxide powder in negative electrode production. It is best used in combination with graphene (RGO), which improves the electrochemical lithium storage performance of the composite materials.

The combined effect of tungsten trioxide and graphene results in a reversible specific capacity of WO3/RGO nanocomposites at 0.1C. This capacity exceeds that of both WO3 and RGO monomers and is higher than their summed capacities.

WO3/RGO nanocomposites exhibit stable cycle performance and good rate performance. After 100 cycles at 0.1C, the reversible specific capacity remains at 635 mA/g, with a capacity retention rate of 83,4 %. At 5C, the reversible capacity is maintained at 460 mA/g. This value exceeds the theoretical specific capacity of 372 mA/g for graphite anode materials in commercial lithium batteries.

These results indicate the potential application of the tungsten trioxide–graphene composite material in future lithium‐ion batteries. In addition, the development of cobalt‐free batteries is likely to increase the demand for tungsten trioxide.

Conclusion

We thank you for reading this article and hope it provides an answer to the question of how Wolframtrioxid is used in cobalt‐free batteries. For further information on Wolframtrioxid and other tungsten products, please visit Stanford Advanced Materials (SAM).

Stanford Advanced Materials (SAM) is a global supplier of tungsten products with over two decades of experience in manufacturing and distribution. The company provides tungsten products that meet the research and production requirements of its customers. Accordingly, we expect SAM to be your preferred tungsten product supplier and business partner.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

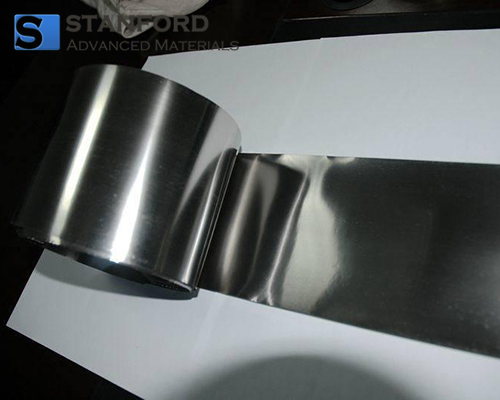

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento