Stanford Advanced Materials Partners With Corridor Crew To Recreate Iconic Liquid Metal Terminator 2 Effect

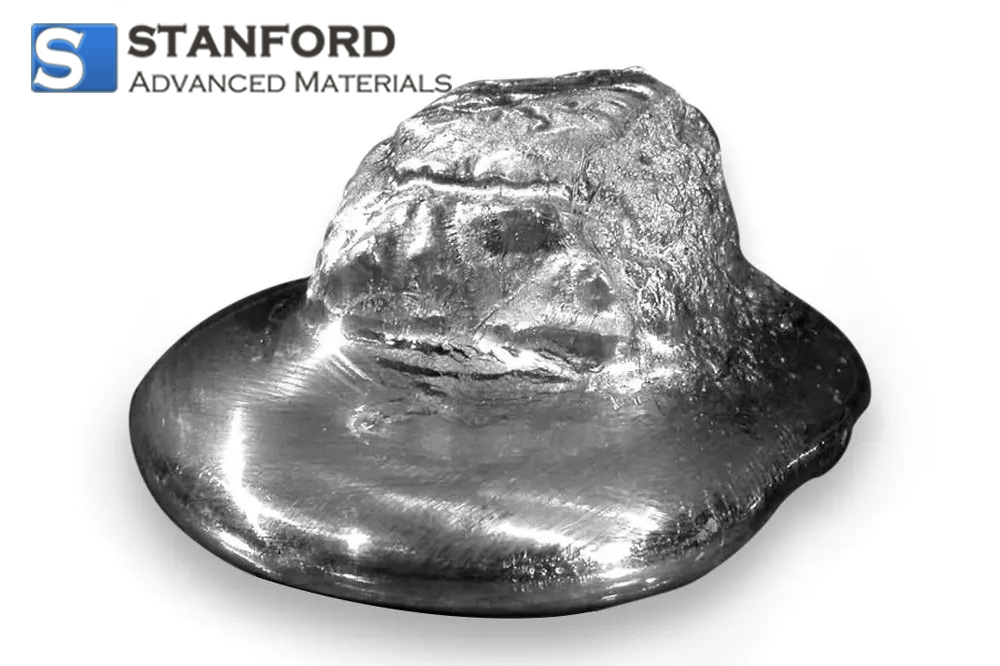

Stanford Advanced Materials (SAM) is pleased to announce its recent collaboration with the popular YouTube special effects team Corridor Crew. The team reproduced the liquid metal effect from Terminator 2: Judgment Day. Corridor Crew has over 6 500 000 subscribers. They analyse film effects using detailed methods. For this project, team member Wren used real gallium metal to replicate the T1000 effect.

The creative request and the partnership agreement

In his initial request, Wren presented a unique idea. He explained, "I am attempting to reproduce the liquid metal effect of the Terminator by using a miniature gallium cast of my head. I will melt the gallium with heat lamps and then reverse the video sequence, thereby allowing the material to assume a new shape." SAM reviewed the proposal using methodical criteria.

Support and project execution

After thorough consideration, SAM decided to support the experiment. Consequently, SAM provided the Corridor Crew with 3 kg of gallium. This provision allowed the team to test the effect in practice rather than relying on CGI. SAM enforced strict safety guidelines for handling the gallium. The material was carefully conserved and returned after use.

Project results and effects

In the final video, Wren and the Corridor Crew detailed the role played by the gallium supplied by SAM. In the video, Wren stated, "Of all those I approached, only Stanford Advanced Materials showed interest, and they made this project possible." The Corridor Crew achieved a reproduction of the liquid metal effect that references the scene from Terminator 2 through the use of gallium.

This collaboration informed many viewers regarding the specific properties and potential applications of gallium metal. SAM continues to supply high-quality metal materials and technical support for various industries. SAM will support future projects that advance material science.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento