What Are The Characteristics Of Hexagonal Boron Nitride?

Introduction

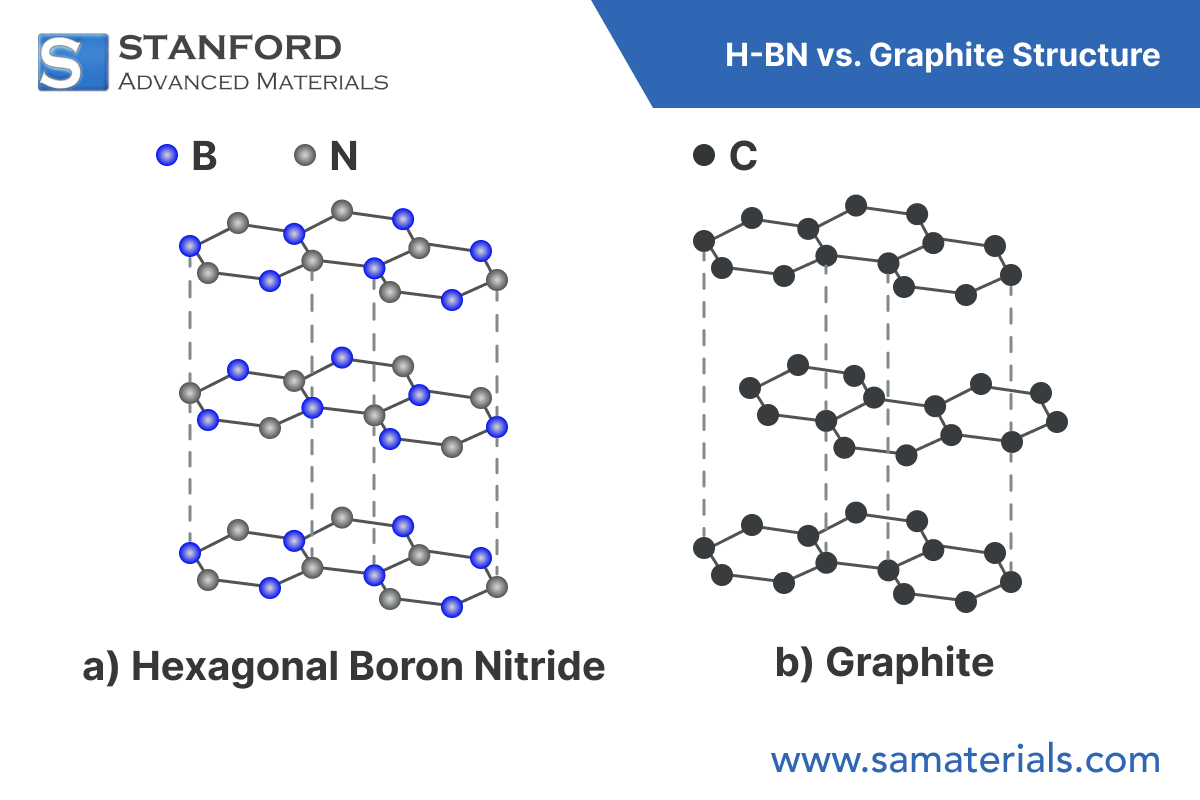

Hexagonal Boron Nitride is also known as white Graphite. In hexagonal boron nitride the nitrogen and boron atoms form flat hexagonal layers that stack to form crystals. The crystal structure exhibits diamagnetic behaviour and marked anisotropy. The crystal parameters are comparable to those found in graphite. Owing to measured properties, boron nitride is used for refractory materials, semiconductor solid-state dot sources, structural components for atomic stacks, packaging designed to reduce neutron radiation, parts for rocket engines, high-temperature lubricants and mould release agents. This article presents the properties of hexagonal boron nitride.

Properties of hexagonal boron nitride

Properties of Hexagonal Boron Nitride

The measured properties of hexagonal boron nitride as a chemical additive are:

Hexagonal boron nitride (white graphite) is a loose, lubricating, moisture-absorbing white powder with an actual density of 2.27/cm³, a Mohs hardness of 2 and a low mechanical strength, which is marginally higher than that of graphite. It does not exhibit a distinct melting point and sublimates at 3000 ℃ under 0.1 MPa nitrogen. Its stability in an oxygen atmosphere is low, and its suitable operating temperature is below 1000 ℃.

Hexagonal boron nitride has a low coefficient of thermal expansion and a high thermal conductivity. Consequently, the material endures thermal cycling between 1200 ℃ and 20 ℃ for hundreds of cycles without damage. The thermal expansion coefficient of boron nitride corresponds to that of quartz, though its thermal conductivity is 10 times that of quartz.

Hexagonal boron nitride conducts heat and functions as an electrical insulator. Its specific resistance at room temperature reaches between 10^16 and 10^18 Ω·cm. Even at 1000 ℃, the specific resistance remains in the range of 10^4 to 10^6 Ω·cm. The dielectric constant measures between 3 and 5, with a dielectric loss of (2–8)×10⁻⁴, and the breakdown strength is approximately double that of Al₂O₃, achieving 30–40 kV/mm.

Applications

Owing to its lubricating functionality, resistance to oxidation and corrosion, insulating capability, thermal conductivity and chemical stability, hexagonal boron nitride is utilised in the following sectors:

-

Production of TiB₂/BN composite ceramics, refractory materials and hard substances

-

Manufacture of rolled steel separation rings for horizontal continuous rolling processes

-

Formulation of high-temperature resistant lubricants and coatings

-

Provision as a raw material for the synthesis of cubic boron nitride (c-BN)

Furthermore, boron nitride exhibits chemical stability. It does not wet or affect most metal melts such as steel, stainless steel, aluminium, iron, germanium, bismuth, silicon, copper, antimony, tin, indium, cadmium, nickel and zinc. Consequently, it is employed as a protective covering for high-temperature galvanic pairs, crucibles, pipes for liquid metals, pump components, grinding tools made from cast steel and electrical high-temperature insulating materials.

Given its resistance to heat and corrosion, boron nitride is also applied in high-temperature components, linings for rocket combustion chambers, heat shields for spacecraft and corrosion‐resistant parts for magnet flux generators.

Conclusion

We thank you for reading this article and trust that it assists in understanding the properties of hexagonal boron nitride. For further technical information regarding boron nitride, please visit Stanford Advanced Materials.

As a global supplier of hexagonal boron nitride products, Stanford Advanced Materials (SAM) has over 20 years’ experience in the production and distribution of hexagonal boron nitride. The company provides products that meet stringent research and production requirements. We expect that SAM will serve as your supplier and business partner for boron nitride.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento