What Is The Spherical Boron Nitride?

What is the spherical Boron Nitride? What is the hexagonal Boron Nitride? What differences exist between spherical Boron Nitride and hexagonal Boron Nitride? If you seek answers to these questions, you are at the correct location. This article examines spherical and hexagonal Boron Nitride in detail.

What is spherical Boron Nitride?

Hexagonal Boron Nitride (H-BN) is a covalently bonded crystal composed of boron and nitrogen atoms. It is known as "white graphene" due to its layered structure, light appearance and moisture-absorbing behaviour. Commercial H-BN products are modified to exhibit different morphologies. These include BN plates, BN aggregates, BN nanosheets, standard BN and spherical Boron Nitride.

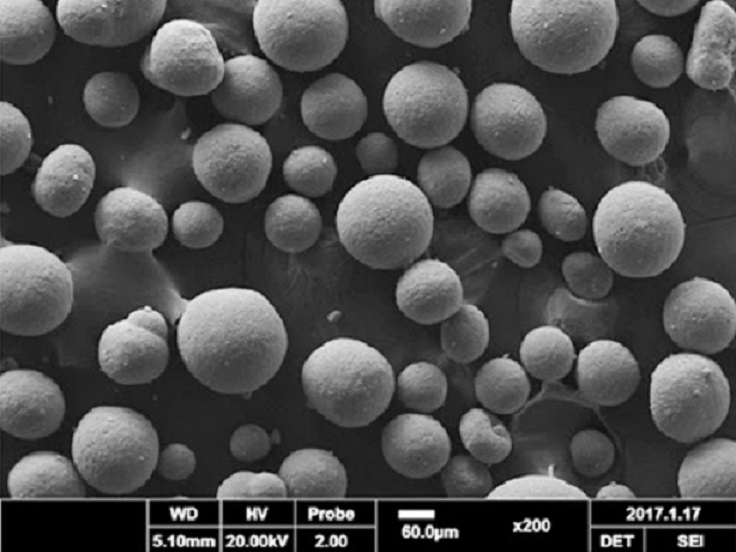

Spherical Boron Nitride is a polycrystalline sphere made from micron-scale BN. It retains BN properties such as low ionic contamination, a low thermal expansion coefficient and high dielectric strength. It also offers improved particle fluidity and a higher specific surface area.

The properties and primary applications of spherical BN materials are as follows:

-

Composite "High Thermal Conductivity Filler"

Boron Nitride exhibits high thermal conductivity. It is used as a thermally conductive filler in rubber and polymer composites. The BN filler in current applications is typically in flake form. Its irregular shape leads to lower conductivity perpendicular to the crystal plane. Consequently, some flakes do not align with the optimal thermal path when filled in the polymer.

In contrast, spherical BN has isotropic properties and a higher specific surface area. This compensates for orientation limitations in polymers and meets the demands for high filler content and improved thermal conductivity.

-

Lubricant Additives

Current lubricant additives offer a limited service life and load-bearing capacity. Hexagonal BN provides satisfactory lubrication, particularly at elevated temperatures. BN is used in industrial applications such as ceramic engine protection agents by recognised German lubricant manufacturers. Spherical BN nanoparticles retain BN’s properties and show higher wear resistance than other forms. They are expected to reduce wear when utilised as lubricant additives.

-

Release Agents

Boron Nitride offers improved high-temperature stability over conventional release agents such as graphite and carbon black, and it exhibits effective lubricity. In industrial applications, BN in plate form is used as a release agent. Spherical BN has a compact mass and isotropic properties. Therefore, its use in die-casting, metallurgy and glass mould release improves process efficiency and extends mould life.

-

Refractory Coatings

At 900℃, Boron Nitride oxidises in an oxidising atmosphere. Its maximum safe operating temperature in vacuum may reach 2000℃. Thus, it finds use in refractory applications. BN coatings are produced with BN particles between 20 and 50 microns. Their performance improves when fixed to refractory materials or when incorporated into refractory layers. Spherical BN shows greater stability and more uniform distribution due to its isotropic properties.

-

Adsorptive Materials

Spherical BN offers a high specific surface area. It is used for the adsorption of organic contaminants. It is synthesised by a hydrothermal method using a template. The template is removed by calcination. The precursor is then cracked at high temperature under protective gas. Finally, BN is produced by a soaking process. The product has a porous structure and high adsorption capacity, and it can be reused. This property allows its application in water treatment, cleaning and energy source purification.

-

Carrier Materials

Boron Nitride is highly resistant to heat and is chemically inert. It meets the criteria for stable catalyst support materials in high-temperature oxidising environments. It does not react with the catalyst. This results in improved catalytic efficiency. The pertinent data are presented in the figure below.

-

Other Applications

In biomedical research, spherical BN is used as a carrier for drug loading and controlled release. The hollow structure offers a large internal volume. This volume can be used for the storage of genes and biological molecules, thereby supporting controlled release.

The properties and application fields differ by BN particle size, purity and contamination levels. Spherical BN with particle sizes of 10 to 20 microns is generally used for refractory surface coatings. BN with particle sizes of 50 to 100 microns is typically used for lubricants, release agents, insulation and thermally conductive materials in high-temperature environments. Particles larger than 100 microns are principally used for hot-pressed BN raw materials. BN may also be classified based on ceramic, thermal conductivity and lubricity performance.

In summary, spherical BN combines the inherent properties of BN with the benefits of a spherical morphology. It overcomes the anisotropic limitations of lamellar BN and the variation in thermal conductivity between different orientations. Spherical BN offers a broader application spectrum and improved performance compared to conventional BN. It is anticipated that further research into BN formation mechanisms and synthesis methods will increase its role in organic-inorganic composites.

Conclusion

We appreciate your review of this article. We hope it has provided a clearer understanding of spherical and hexagonal Boron Nitride. For additional information, please visit Stanford Advanced Materials (SAM).

Stanford Advanced Materials has over two decades of experience in the manufacture and supply of BN. It meets research and production requirements with high-quality BN products. We trust that SAM will be your preferred BN supplier and business partner.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento