Case Study: Unlocking The Value Of Investment-Grade Tantalum Discs

Introduction

Investment Grade Metals, including Tantalum, have gained significance in various industrial sectors as valuable resources. Tantalum discs (Ta discs) are a specific form of tantalum with quantifiable properties that serve high-performance applications. This article details the benefits and applications of these discs to improve understanding.

[1]

[1]

Figure 1. Investment Grade Metals

Benefits of Tantalum Discs in Investment Grade Quality

Tantalum discs in investment grade quality provide several measurable benefits for diverse industrial applications.

High Purity and Quality: The discs demonstrate high levels of purity and quality. They are manufactured according to stringent technical specifications to minimise the inclusion of impurities that might affect performance.

Precise Dimension Control: The discs are produced with exact dimension control. Their consistent measurements facilitate integration into technical systems.

Chemical Inertness: Tantalum is recognised for its resistance to corrosion and chemical attack. The discs retain these properties and are used in environments that require resistance to chemical degradation, such as aerospace, chemical processing, and semiconductor manufacturing.

High Melting Point: Tantalum possesses a high melting point. Consequently, the discs maintain structural integrity at elevated temperatures, an essential factor in industrial processes involving high heat.

Biocompatibility: Tantalum is biocompatible. It is thus used in medical devices, including implants and prostheses, where compatibility with human tissue is required.

Electrical and Thermal Conductivity: The discs exhibit both electrical and thermal conductivity. These properties support applications that require efficient heat dissipation and reliable electrical performance.

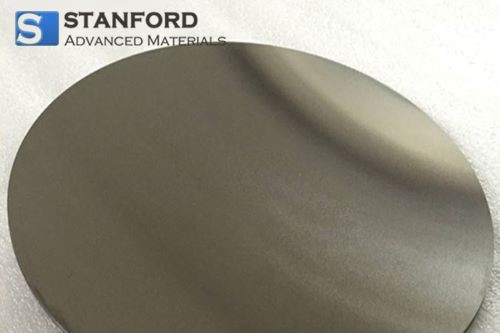

Figure 2. Tantalum Disc TA0007 (Ta disc)

Applications of Tantalum Discs in Investment Grade Quality

These tantalum discs are utilised across multiple industrial sectors:

Aerospace and Defence: They are employed in critical aerospace components including propulsion systems, structural elements and electronic devices, where durability and corrosion resistance are required.

Semiconductor Industry: They are utilised in the semiconductor fabrication process owing to their chemical inertness and thermal stability for components such as sputter targets and crucibles.

Medical Devices: The biocompatibility of tantalum leads to its application in medical implants used in orthopaedics and dental care, thereby contributing to device longevity and patient welfare.

Chemical Processing: Tantalum is used in environments involving aggressive chemicals. Its discs are installed in processing equipment designed for chemical handling.

Research and Development: The discs are applied in research projects, thereby supporting experimental studies and technological progress.

Conclusion

In summary, tantalum discs in investment grade quality present measured purity, precise dimension control, chemical inertness and biocompatibility. They contribute to performance in aerospace, medical devices, semiconductor manufacturing and other technical sectors. Tantalum discs in various sizes are available from Stanford Advanced Materials (SAM). Please send an enquiry if you are interested.

Reference:

[1] (18/03/2020). Gold rutscht um fast 3 %, da die Angst vor einem Virus die Anleger zu Bargeld treibt. CNBC. Retrieved on 16/08/2023, from https://www.cnbc.com/2020/03/18/gold-markets-us-federal-reserve-coronavirus-in-focus.html

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento