All About Niobium-Titanium Superconducting Materials

Introduction

Superconducting materials have been implemented in many modern devices. They are employed in systems that require efficient magnetic and electrical conduction. Niobium‐titanium is used frequently. This alloy is characterised by flexibility, low cost and consistent performance under extremely low temperatures. Its use in technical applications provides practical benefits.

Composition and Structure

Niobium‐titanium alloys typically consist of approximately 47% niobium and 53% titanium. This ratio may vary slightly according to application requirements. The alloy’s structure is based on a body-centred cubic arrangement. In simple terms, the atoms form a stable, repetitive pattern.

The superconducting state is achieved when the material is cooled below approximately 9.2 Kelvin. At these low temperatures, the alloy exhibits zero electrical resistance. This property is significant for precision applications in which energy losses are critical.

Further reading: Types of Superconducting Materials and Their Applications

Superconducting Properties

The superconducting behaviour of niobium‐titanium is defined by several quantifiable properties.

The critical temperature is approximately 9.2 Kelvin. When subjected to strong magnetic fields, superconductivity is maintained up to nearly 15 Tesla.

The critical current density remains high, particularly in wires that consist of multiple strands. This high current density allows the alloy to handle large currents without losses.

Given these properties, niobium‐titanium alloys are suitable for use in demanding operational environments.

Advantages of Niobium-Titanium Superconductors

The niobium‐titanium alloy offers several practical advantages.

Firstly, it may be drawn into thin wires and formed into complex multifilament structures due to its high ductility. This processing ability is uncommon among superconductors.

Secondly, its cost is relatively low compared with certain high-temperature superconductors or other types such as niobium-tin.

Thirdly, its mechanical strength is high. It withstands elevated electromagnetic forces and thermal stresses consistently.

Finally, the alloy may be easily combined with stabilising metals such as copper or copper-nickel. This procedure ensures that the superconducting wires remain safe in the event of a sudden loss of superconductivity.

Common Applications

Niobium‐titanium forms the basis of many modern electromagnetic devices.

In magnetic resonance imaging (MRI) scanners it is the primary material used for the main coils. Consequently, hospitals obtain clear images. Particle accelerators in research centres utilise niobium‐titanium coils for precise steering and focusing of particle beams. In equipment such as the Large Hadron Collider these superconducting magnets are essential. Fusion facilities that employ magnetic confinement, for example Tokamak reactors, rely on niobium‐titanium coils to generate safe and strong magnetic fields. Research laboratories use small high-field magnets made from this alloy. It is also applied in superconducting magnetic energy storage systems, where rapid discharge is required to maintain energy stability during peak loads.

Limitations

Despite its many advantages, niobium‐titanium superconductors have certain limitations.

The material must be cooled with liquid helium because its superconductivity occurs only at very low temperatures. Consequently, this requirement may increase costs and technical complexity.

The alloy ceases to be superconducting in magnetic fields significantly exceeding 15 Tesla. Consequently, its use in applications requiring very high fields is limited.

In contrast to some high-temperature superconductors, it is less effective in higher temperature environments. These issues have been considered alongside its benefits in many practical contexts.

Frequently Asked Questions

Q: What is the typical composition of a niobium‐titanium alloy?

Q: The typical composition is approximately 47% niobium and 53% titanium.

Q: At what operating temperature does niobium‐titanium exhibit superconductivity?

Q: Niobium‐titanium begins to exhibit superconductivity below approximately 9.2 Kelvin.

Q: In which important devices is niobium‐titanium employed?

Q: It is commonly used in magnetic resonance imaging scanners for hospital magnet coils.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

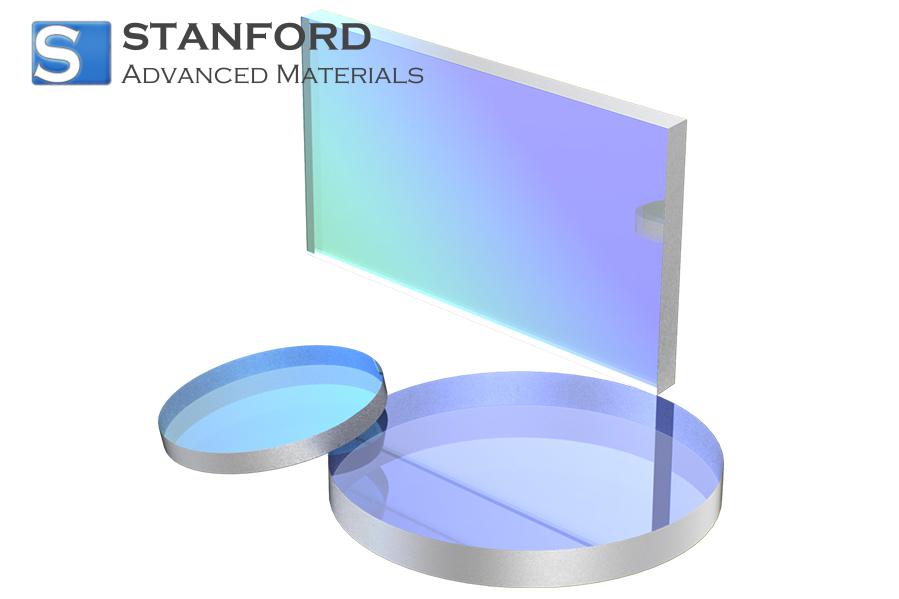

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento