Ceramic: Common Types And Applications

Description

Ceramics are indispensable materials due to their specific properties and versatility. An understanding of the various ceramic types and their applications provides valuable insight into their significance for modern scientific research and daily use.

Properties of Ceramics

Ceramics are known for their defined properties that suit them for a range of applications. The following properties are important:

- Hardness: Ceramics are generally very hard, which makes them resistant to wear and abrasion.

- High Melting Point: They tolerate elevated temperatures without decomposing, making them suitable for high‐temperature environments.

- Brittleness: Although hard, ceramics tend to fracture under load.

- Electrical Insulation: Many ceramics provide excellent electrical insulation, a benefit for electronic applications.

- Chemical Resistance: Ceramics resist chemical corrosion and degradation.

- Low Thermal Conductivity: They conduct heat poorly, which is advantageous for thermal barriers.

Common Types of Ceramics and Their Applications

Alumina (Al₂O₃)

Alumina is widely used because of its hardness, high melting point, and effective electrical insulation. It is applied in:

- Cutting tools

- Electrical insulators

- Biomedical implants

Boron Nitride (BN)

Boron Nitride is produced in various forms. The hexagonal form is analogous in structure to graphite. It is used in:

- Lubricants

- Refractory materials

- Electronic components

Boron Carbide (B₄C)

Boron Carbide is one of the hardest known materials. It is therefore used for:

- Armour plating

- Abrasives

- Neutron absorption in nuclear reactors

Cerium Hexaboride (CeB₆)

CeB₆ is noted for its low work function and high melting point. It is applied in:

- Electron emitters in vacuum tubes

- Plasma sources

- Catalysts

Silicon Carbide (SiC)

Silicon Carbide combines high hardness with thermal stability. Its applications include:

- Semiconductor components

- High-temperature applications

- Abrasive processing

Silicon Nitride (Si₃N₄)

Silicon Nitride offers excellent resistance to temperature fluctuations and mechanical strength. It is used in:

- Engine components

- Bearings

- Cutting tools

Zirconium Dioxide (ZrO₂)

Zirconium Dioxide is recognised for its high fracture toughness and thermal expansion properties. It finds use in:

- Dental crowns and bridges

- Thermal barrier coatings

- Fuel cell membranes

Comparison of Common Ceramics

|

Ceramic Type |

Key Properties |

Common Applications |

|

Alumina (Al₂O₃) |

High hardness, electrical insulation |

Cutting tools, biomedical implants |

|

Boron Nitride (BN) |

Lubricating properties, thermal stability |

Lubricants, electronic components |

|

Boron Carbide (B₄C) |

Extremely hard, neutron absorber |

Armour plating, abrasives, nuclear reactors |

|

Low work function, high melting point |

Electron emitters, plasma sources |

|

|

Silicon Carbide (SiC) |

High hardness, thermal stability |

Semiconductors, high-temperature applications |

|

Silicon Nitride (Si₃N₄) |

Resistance to temperature fluctuations |

Engine components, bearings, cutting tools |

|

Zirconium Dioxide (ZrO₂) |

High fracture toughness |

Dental applications, thermal barrier coatings |

Frequently Asked Questions

How do ceramics differ from metals and polymers?

Ceramics are generally harder and more brittle than metals. They provide better insulation for electricity and heat than polymers. Metals conduct electricity more efficiently and have lower melting points.

Why is aluminium oxide frequently used in biomedical implants?

Aluminium oxide is biocompatible; it does not provoke adverse bodily reactions. Its high hardness and wear resistance justify its use in joint replacements and other implantable devices.

How does the brittleness of ceramics affect their applications?

The brittleness of ceramics indicates that they may fracture under load. Consequently, they are unsuitable for applications requiring high toughness. Their hardness permits their use in cutting tools and armour plating.

What benefits does the use of zirconium dioxide offer in dentistry?

Zirconium dioxide exhibits high strength and acceptable aesthetic quality. It replicates the appearance of natural teeth and provides extended durability in crowns and bridges.

Can ceramics conduct electricity?

Most ceramics act as excellent electrical insulators because they contain no free electrons. However, under specific conditions, some forms of boron nitride may display electrical conductivity.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

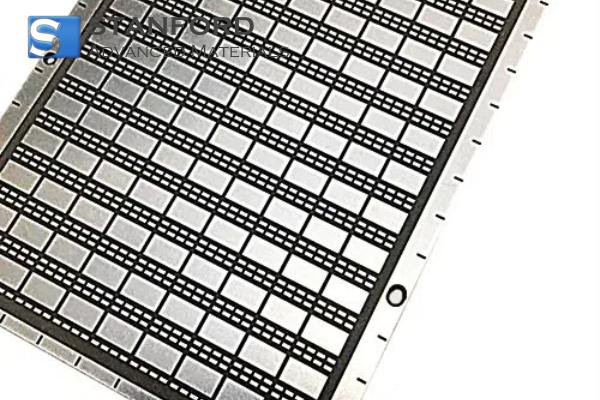

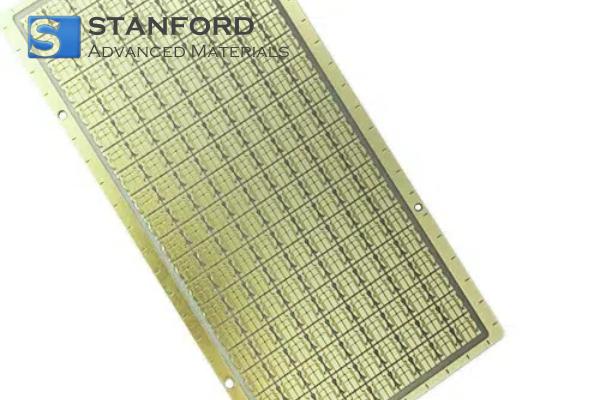

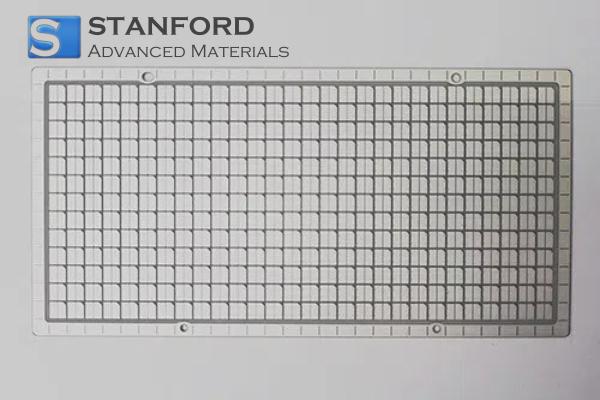

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento