Tantalum: Element Properties And Uses

Description

Tantalum is a rare and highly durable metal characterised by notable chemical and physical properties. Its primary applications are based on its high resistance to corrosion, and it has a wide range of applications, including in electronics and aerospace industries. This element has the atomic number 73 and belongs to the group of transition metals. It constitutes an essential component in several high-performance uses owing to its distinctive properties.

Introduction to the Element

Tantalum's use as an industrial material began in the early 19th century when the Swedish chemist Carl Wilhelm Scheele first identified it within the mineral columbite in 1802. The metal was named after Tantalus, the Greek mythological figure who was perpetually tantalised by unattainable desires. Indeed, the name fits the metal well because it is stubbornly resistant to corrosion, hence "untouchable" by many chemical agents.

Tantalum is a dense, hard, blue-grey metal that has a very high melting point of 3,017°C (5,463°F), which enables its use in extreme conditions. One of the main reasons tantalum is used in the aerospace industry is its resistance to high temperatures without failure. It thus finds applications in both chemical processing and biomedical areas due to its physical properties, such as resistance to acids and bases.

Chemical Properties Description

The most striking chemical property of tantalum is its resistance to corrosion. The metal forms a thin, stable oxide layer when exposed to oxygen. This oxide layer, often merely a few nanometres thick, prevents further corrosion and serves to protect the integrity of the metal in highly corrosive environments. This behaviour is particularly helpful in industries where materials are commonly exposed to aggressive chemical environments.

For example, tantalum resists attack from aqua regia—one of the most aggressive acid combinations—hydrofluoric acid, sulphuric acid, and chloride solutions, among others. Therefore, tantalum is very important in chemical processing equipment, such as reactors, heat exchangers, and pipes that face corrosive substances.

Another critical reason that tantalum is used for biomedical implants is its inertness. The human body maintains a variety of pH levels in different regions and also contains various types of chemicals that could lead to the corrosion of poorer-quality metals. This indicates that implants, including joint replacements, dental implants, and stents, have long service lives and do not corrode with the body's fluids.

Physical Properties Data Table

Tantalum features excellent physical properties, which make it fit for demanding applications. Below are the summarised key physical properties:

|

Property |

Value |

|

Atomic Number |

73 |

|

Atomic Weight |

180.95 u |

|

Melting Point |

3017 °C |

|

Density |

16.65 g/cm³ |

|

Thermal Conductivity |

57.5 W/(m·K) |

|

Electrical Resistivity |

13.1 µΩ·cm |

|

Hardness |

Approximately 6.5 Mohs |

|

Crystal Structure |

Hexagonal |

From the table, it is observed that the melting point and the density of tantalum are very high; this accounts for the durability of tantalum in high-temperature applications. The metal also has a relatively high value for thermal conductivity and electrical resistivity, hence useful in electronics and related technologies. For more information, please check Stanford Advanced Materials (SAM).

Common Uses

The many uses of tantalum arise from its unique combination of corrosion resistance, high melting point, and biocompatibility. Following is a list of some of the main industries and areas in which tantalum is applied:

Electronics Industry

Tantalum's most important industrial use is in the manufacture of electronic components, especially capacitors and resistors. Because of its resistance to corrosion, strength, and conductivity, tantalum capacitors are in demand in mobile phones, computers, tablets, and other high-performance electronics that require storage and regulation of charge over time.

For instance, Apple Inc. uses tantalum capacitors in all its iPhones and other devices to ensure reliable performance in the compact and power-efficient designs of contemporary electronics. These tantalum capacitors are chosen because of their small size, high reliability, and great stability; thus, they are very suitable for high-frequency applications in telecommunications, computing, and automotive systems.

Aerospace and Defence

Due to its high melting point and strength at elevated temperatures, tantalum is an important component in aerospace applications, especially for high-temperature alloys. The aerospace industry uses tantalum in jet engines, rocket nozzles, and missile components. These parts must withstand extreme temperatures, often so high that other conventional metals cannot tolerate them, making tantalum one of the best materials for these applications.

Biomedical Applications

The property of tantalum being biocompatible makes it highly suitable for hip replacements, knee implants, and dental devices. Given that it does not react with bodily fluids, tantalum is safe for long-term implantations within the human body. Biomet uses tantalum in joint implants that provide durability and flexibility for patients who require surgical solutions.

Chemical Processing

Tantalum's resistance to corrosion also extends the use of the metal in the chemical industry. It is used in the manufacture of heat exchangers, reactors, and valves, particularly in medium and extreme conditions where other metals would quickly deteriorate. An example of such applications is in the manufacture of pharmaceuticals, where the inertness of the metal ensures product integrity, particularly in conditions involving highly corrosive chemicals.

Preparation Methods

Tantalum is primarily extracted from ores such as columbite-tantalite or coltan and microlite. The extraction includes a multi-step process:

1. Mining: Tantalum is mined from ore, usually coltan, which is largely found in Africa, Australia, and Brazil.

2. Ore Processing: The ore is processed to separate the tantalum from other elements. This is typically done through a mechanical separation process and chemical treatments that remove impurities.

3. Purification: Following the initial extraction, the tantalum is purified using techniques such as solvent extraction and electrolysis. These methods help eliminate unwanted elements and ensure that the final metal has a high level of purity, normally higher than 99%.

4. High-Temperature Reduction: Finally, tantalum is purified by reducing tantalum halides at high temperatures, such as tantalum chloride, to pure tantalum metal.

Conclusion

Tantalum is a rare, highly valued metal possessing a range of superior properties that render it indispensable for modern electronics, aerospace industries, and chemical processes. Its resistance to corrosion, high melting point, and biocompatibility ensure that this tantalum remains critical for applications requiring high durability and stability. Given that technology continues to progress, the demand for tantalum will likely increase, particularly as evolving electronics and medical industries emerge.

Frequently Asked Questions

1. What is the atomic number of tantalum?

Tantalum has an atomic number of 73.

2. How is tantalum extracted from its ore?

Tantalum is extracted from columbite-tantalite through the process of mechanical separation followed by chemical processing and purification.

3. Why is tantalum used in electronics?

Tantalum has very good corrosion resistance, stability, and high capacitance; hence, it finds most of its applications in the manufacture of capacitors and resistors in electronics.

4. What are the preparation methods to obtain pure tantalum?

Tantalum metal in high purity is produced by the procedures of solvent extraction, electrolysis, and high-temperature reduction of tantalum halides.

5. How do the chemical properties of tantalum contribute to its industrial applications?

Tantalum's resistance to corrosion and passivation with the formation of a protective oxide layer provide an important basis for a number of applications in environments where durability and stability are required, such as chemical processing equipment and biomedical implants.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

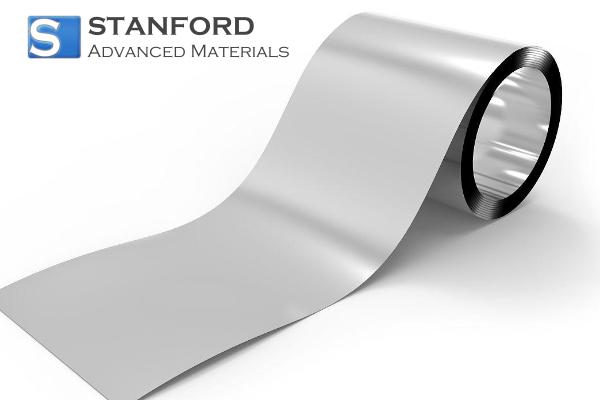

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento