Tungsten: Element Properties And Uses

Description

Tungsten is a rare, high-density element with the highest melting point among metals and significant mechanical strength that is essential for various industrial and scientific applications.

Introduction to the Element

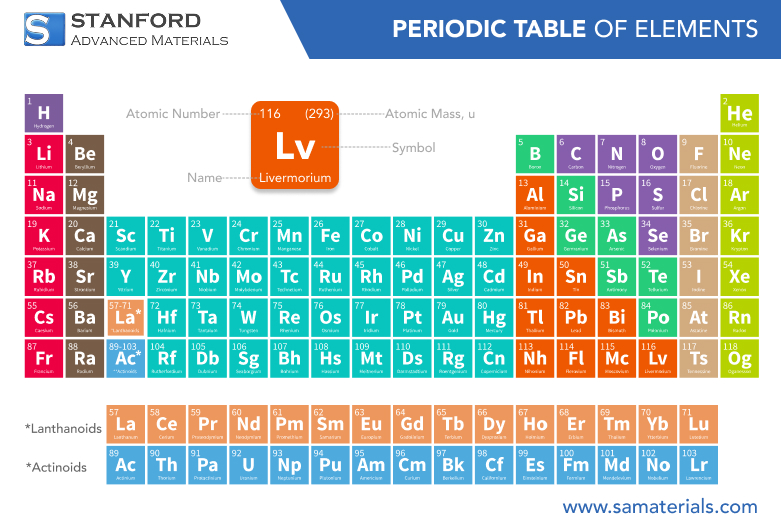

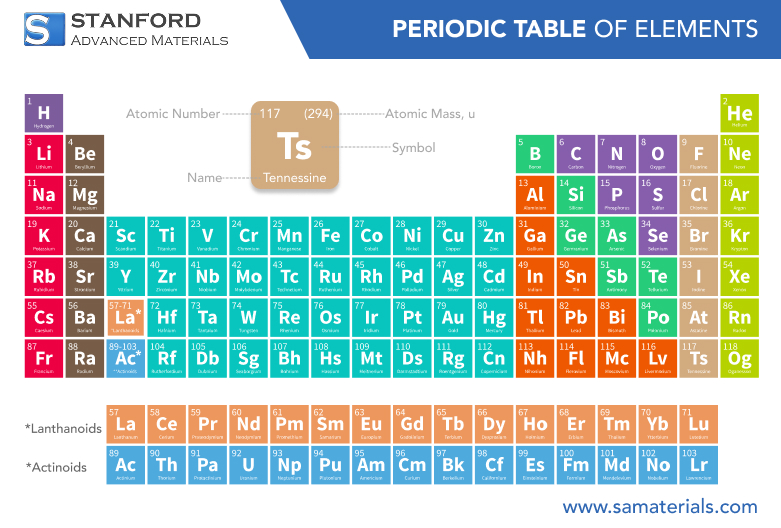

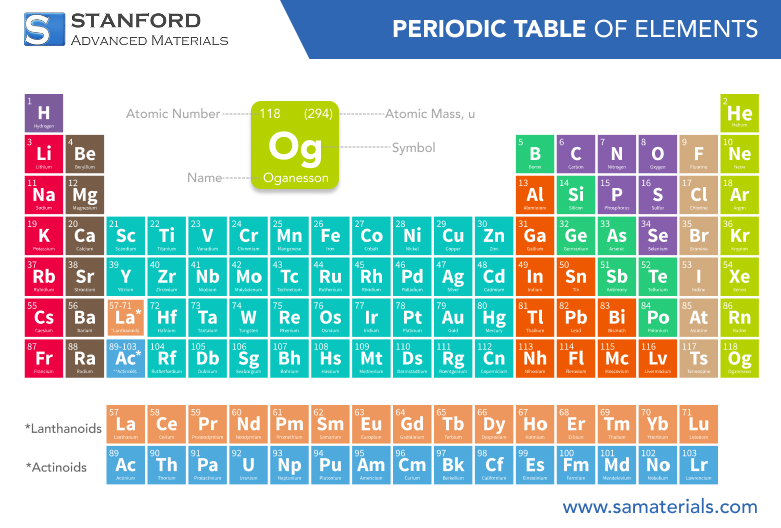

Tungsten, represented in the periodic table by the symbol W, has an atomic number of 74 and an atomic weight of approximately 183.84. It was discovered in the late 18th century and is classified as a refractory metal due to its ability to withstand extremely high temperatures.

Description of Chemical Properties

Tungsten exhibits several chemical properties that contribute to its wide range of applications. Its corrosion and oxidation resistance remain effective even at elevated temperatures. This chemical stability ensures that tungsten retains its composition in demanding environments. The element forms compounds with oxygen, sulphur and halogens and generally maintains an oxidation state of +6 in many chemical reactions.

Physical Properties Table

|

Property |

Value |

Units |

Notes |

|

3422 |

°C |

Highest melting point among metals |

|

|

Boiling point |

5930 |

°C |

Approximate value |

|

Density |

19.25 |

g/cm³ |

At room temperature |

|

Thermal conductivity |

173 |

W/m-K |

Heat transfer capability measured at 173 W/m-K |

|

Electrical specific resistance |

5.5e-8 |

Ω-m |

This value is used in electrical performance calculations |

For further information, please visit Stanford Advanced Materials (SAM).

Common Uses

Tungsten is employed in several industries due to its unique physical properties. In the lighting industry, tungsten is used to manufacture incandescent lamp filaments. Its exceptionally high melting point ensures that filaments can operate at elevated temperatures without melting or disintegrating.

In addition to lighting, tungsten is utilised in the production of electrical contacts and welding electrodes, where its durability and high-temperature resistance are required. The aerospace and defence industries use tungsten to manufacture counterweights and armour-piercing components.

Tungsten is also applied in medical devices, especially in equipment that demands precise operation and radiation resistance. It is further used in high-speed tools and specialised machinery, thereby contributing to modern manufacturing processes.

Preparation Methods

Tungsten processing is carried out using advanced industrial techniques designed to extract and purify the element from its natural ores. The principal sources of tungsten are minerals such as wolframite and scheelite.

The ores are first subjected to a concentration process to separate tungsten-bearing minerals from other materials. The concentrated ore is then chemically treated, typically converting it into tungsten oxide. This oxide is subsequently reduced in a high-temperature environment to produce pure tungsten metal. Modern preparation methods focus on efficiency and sustainability, employing techniques such as solvent extraction and ion exchange to achieve improved yield and purity.

Frequently Asked Questions

What is tungsten primarily used for?

Tungsten is mainly employed in high-temperature applications, for example, in lamp filaments, welding electrodes and heavy industrial tools.

How is tungsten extracted from its ores?

Tungsten is obtained from minerals such as wolframite and scheelite by a process that includes ore concentration, chemical conversion to tungsten oxide and high-temperature reduction.

By which property does tungsten distinguish itself among metals?

Its extremely high melting point and chemical stability allow tungsten to maintain performance under conditions where most metals fail.

Is tungsten found in consumer goods?

Yes, tungsten is present in various consumer and industrial products, including electronics, medical devices and machine components.

How do tungsten-based products contribute to industrial performance?

Tungsten products are employed due to their high durability, significant temperature resistance and load capacity in demanding industrial applications.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

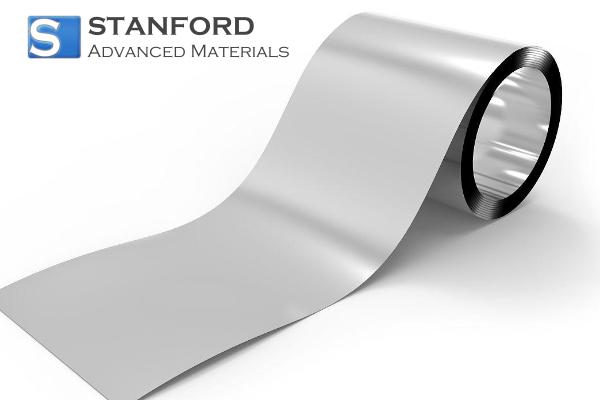

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento