Rhenium: Element Properties And Uses

Rhenium (Re) is a rare, high-melting-point metal used in jet engines, superalloys, and catalysts. Known for its strength and corrosion resistance, it is a byproduct of molybdenum and copper refining.

Introduction

Rhenium is one of the rarest elements in the Earth's crust and has captured the attention of scientists and engineers due to its exceptional characteristics. As an introduction to the element, rhenium has been recognised for its high melting point and outstanding resistance to wear and corrosion. Discovered in the early 20th century, this transition metal quickly gained importance because of its applications in high-temperature superalloys and catalytic processes.

Chemical Properties Description

Rhenium exhibits a variety of chemical behaviours that make it particularly interesting for scientific investigation. Rhenium can form stable compounds in several oxidation states, most notably +7, +6, and +4. This flexibility in oxidation states allows rhenium to participate in various catalytic cycles and chemical reactions, especially in oxidation-reduction processes.

In many compounds, rhenium forms strong bonds with oxygen and other electronegative elements, which explains its exceptional resistance to chemical degradation under extreme conditions. Additionally, its ability to combine with other metals and form alloys contributes to its use in high-performance applications. Researchers have noted that rhenium compounds are often employed in catalysts for refining processes and in chemical sensors due to their stability and reactivity under harsh conditions.

Physical Properties Data Table

|

Property |

Value |

Unit |

|

Atomic Number |

75 |

- |

|

Atomic Weight |

186.21 |

amu |

|

Density |

21.02 |

g/cm³ |

|

Melting Point |

3459 |

°C |

|

Boiling Point |

5900 |

°C |

|

Electron Configuration |

[Xe] 4f14 5d5 6s2 |

- |

For more information, please check Stanford Advanced Materials (SAM).

5 Key Uses of Rhenium

- Aerospace Superalloys

Rhenium is a critical component in nickel-based superalloys used in jet engine turbine blades. Even small additions of rhenium enhance the alloy's creep resistance and maintain strength at high temperatures, improving engine efficiency and lifespan. - Catalysis in Petroleum Refining

Rhenium compounds serve as catalysts in hydrocracking and reforming reactions, enabling the conversion of crude oil into high-octane fuels. Its chemical stability ensures high activity under harsh reaction conditions. - Thermocouples and Electrical Contacts

Due to its excellent electrical conductivity and thermal stability, rhenium is used in high-temperature thermocouples and electrical contacts, where reliability over a wide temperature range is critical. - Filaments for Mass Spectrometry and Electronics

Rhenium's high melting point and resistance to sublimation make it ideal for filaments in mass spectrometry, ionisation devices, and certain vacuum tube components. - Medical Imaging and X-ray Equipment

Rhenium alloys are also used in specialised medical devices that require high-density metals, including X-ray and radiography equipment. Its ability to withstand heat and mechanical stress ensures precision and safety in clinical applications.

Preparation Methods

Preparation methods for rhenium typically involve complex extraction and refining processes due to its low natural abundance. The extraction of rhenium is often accomplished as a by-product of molybdenum and copper mining, where sophisticated separation techniques are used to isolate the metal from ore residues. Once extracted, rhenium is refined into a pure form through processes such as solvent extraction and ion exchange. These preparation methods are critical for obtaining the high-purity rhenium necessary for industrial applications.

Conclusion

Rhenium is a rare and important element whose combination of high-temperature stability, chemical resilience, and mechanical strength has made it indispensable in aerospace, catalysis, electronics, and medical applications. Its scarcity and demanding preparation methods only underscore its value in advanced industrial processes. For reliable sourcing of high-quality rhenium and rhenium compounds, Stanford Advanced Materials (SAM) provides certified, industrial-grade materials suitable for research, production, and advanced technology applications.

Frequently Asked Questions

What is rhenium?

Rhenium is a rare and heavy transition metal known for its high melting point and excellent chemical stability, which make it valuable for high-temperature applications.

How is rhenium prepared?

Rhenium is typically extracted as a by-product from molybdenum and copper ores, using advanced separation techniques such as solvent extraction and ion exchange.

What are the common uses of rhenium?

Its common uses include incorporation into superalloys for jet engines, catalysts in refining processes, electrical contacts, thermocouples, and high-performance industrial components.

What are the notable chemical properties of rhenium?

Rhenium exhibits multiple stable oxidation states, forms robust bonds with oxygen, and maintains stability under extreme conditions, which are emphasised in its Chemical Properties Description.

How does rhenium contribute to industrial products?

Rhenium improves the high-temperature strength and durability of industrial products such as turbine blades and catalytic converters, making it critical for modern technological applications.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

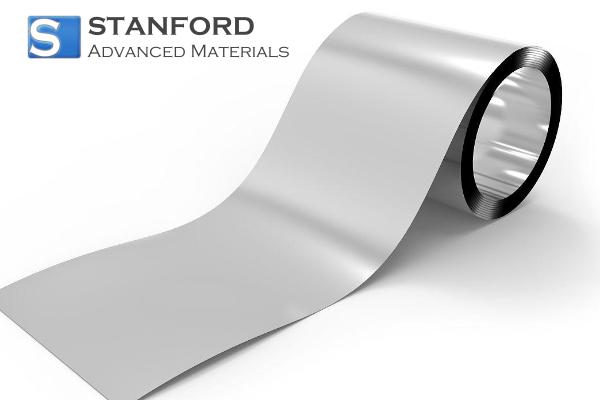

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento