Types Of Niobium-Titanium Superconducting Materials And Their Applications

Description

Superconducting Niobium-Titanium materials have been utilised for decades in scientific and industrial settings, forming the basis for numerous superconducting magnet systems. This article presents various types of these materials. We also describe their applications in magnets, medical devices and research instruments.

Types of Superconducting Niobium-Titanium Materials

Superconducting Niobium-Titanium materials are fabricated from an alloy of niobium and titanium. The material is generally processed into wires or tapes. They exhibit well-documented superconducting properties. The superconducting transition occurs at approximately 9.2 Kelvin. At lower temperatures, they function as perfect conductors.

One form involves a monofilament wire. In this configuration, a continuous strand of the superconducting alloy is embedded in a copper matrix. The copper provides additional thermal and magnetic stability. This design is frequently used in laboratory experiments requiring precision and consistency.

Another common form is the multifilament wire. This consists of numerous fine filaments bundled together. The construction reduces energy losses when the material is subjected to varying magnetic fields. Multifilament wires are employed in superconducting magnets used in MRI machines. The bundled filaments ensure an even distribution of current, thereby contributing to stable magnetic operation.

Niobium-Titanium tapes are also widely used. They are manufactured in a flat, tape-like form. Tapes are selected where a broad, flat conductor is required. They can be wound more easily and minimise the potential for weak areas. This design is common in power transmission and in magnets for particle accelerators.

A further category is known as composite superconductors. In these, niobium-titanium strands are embedded within a copper or aluminium matrix. This design enhances mechanical strength and improves heat extraction during operation. Composite superconductors are used in high-field magnets found in fusion reactors and research laboratories. Their design enables them to withstand high magnetic fields and rapid current variations.

Manufacturers also adjust the heat treatment processes for these materials. The treatment alters the microstructure of the niobium-titanium alloy, thereby affecting both the superconducting properties and overall performance. Engineers use specific heat treatments to optimise the critical current density. Some wires can transmit current densities of up to 3 000 Ampere per square millimetre at 4.2 Kelvin. Consequently, they are regarded as reliable in demanding environments.

Applications of Niobium-Titanium Superconducting Materials

Niobium-Titanium materials have varied and important applications. In medical technology, they are used in MRI equipment to generate strong and stable magnetic fields. In particle accelerators, as used in high-energy physics research, these materials form large magnets for bending and focusing beams. Their use in fusion reactors is increasing. In these reactors, superconducting magnets confine plasma at high temperatures.

Numerous research laboratories have employed niobium-titanium superconductors for precision experiments. The materials are selected for their consistent performance and well-documented properties. Over several years, improvements in processing and construction have increased the performance of these materials. Engineers rely on them for many applications and expect consistent operation under standard conditions.

Niobium-Titanium superconductors are also applied in smaller, specialised devices. Modern power cables employ these superconductors to reduce energy losses over extensive distances. Specific research magnets utilise them because of their defined magnetic field characteristics.

Overall, niobium-titanium superconductors retain a significant role in modern technology. Their consistent performance and predictability lead to frequent selection in experimental setups. The materials have been refined through extensive study and practical application. Engineers and scientists continue to address new challenges, thereby maintaining the relevance of niobium-titanium superconductors.

Summary Table

|

Type of Material |

Design Feature |

Frequent Application |

Main Property |

|

Monofilament Wire |

Single strand within a copper matrix |

Laboratory experiments and precision research |

Even and stable current flow |

|

Multifilament Wire |

Bundled fine strands |

Magnetic resonance imaging devices |

Minimised energy losses and improved stability |

|

Tape Superconductor |

Flat, tape-like form |

Particle accelerators and power transmission systems |

Easier winding with fewer weak spots |

|

Composite Superconductor |

Alloy strands in a copper or aluminium matrix |

Fusion reactors and high-field research magnets |

High current density and mechanical strength |

Further information is available at Stanford Advanced Materials (SAM).

Conclusion

Superconducting Niobium-Titanium materials play a significant role in modern technology. They are available in various forms, such as monofilament wires, multifilament wires, flat tapes and composite superconductors. Each design meets specific requirements. Scientific devices, including MRI machines and particle accelerators, depend on these superconductors for their operation. Their performance has been established through extensive study and practical application. Engineers and scientists continue to address new challenges, thereby maintaining the relevance of niobium-titanium superconductors.

Frequently Asked Questions

Q: What are superconducting Niobium-Titanium materials used for?

Q: They are used for the manufacture of superconducting magnets in medical imaging, particle accelerators, fusion reactors and research instruments.

Q: What is the typical temperature for the superconducting transition?

Q: For niobium-titanium alloys, the transition occurs at approximately 9.2 Kelvin.

Q: Why are composite superconductors important?

Q: Composite superconductors deliver additional mechanical strength and enhanced heat extraction during high current operation.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

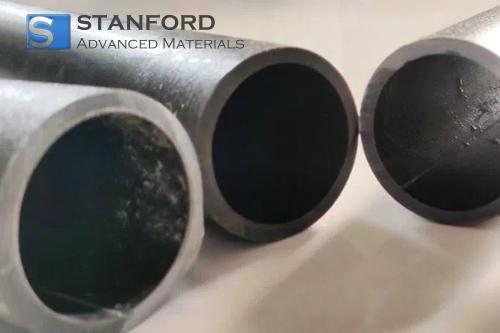

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento