Zirconium: Element Properties And Uses

Description

Zirconium is a strong, corrosion-resistant metal with excellent heat resistance and chemical stability. It is widely used in nuclear reactors, aerospace, medical implants, and industrial applications requiring durability and reliability.

Introduction to the Element

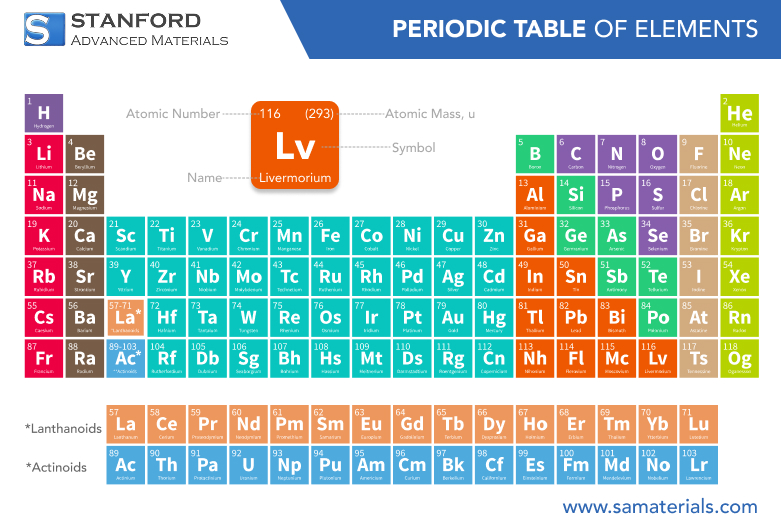

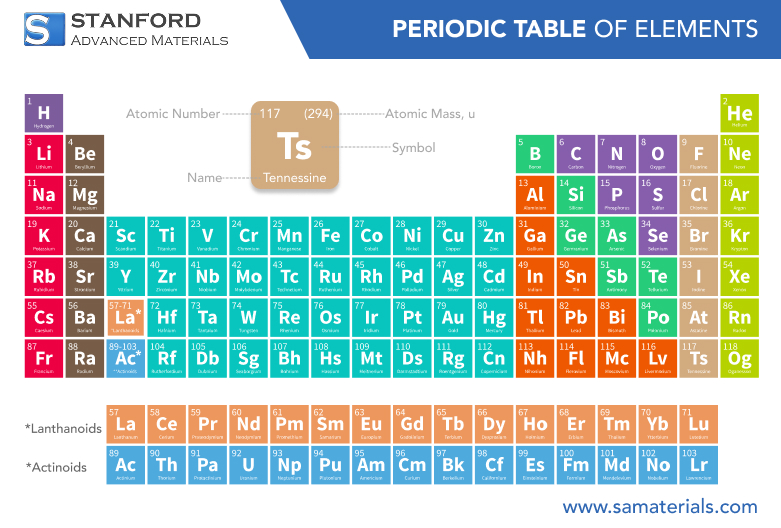

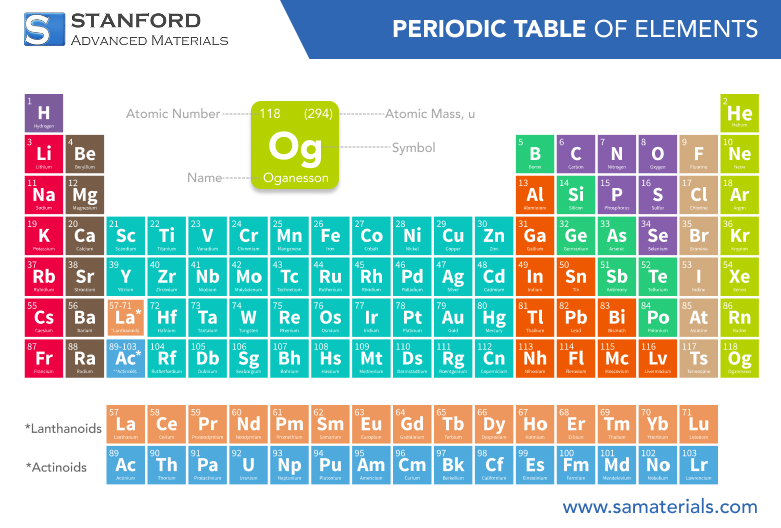

Zirconium is an element that holds a prominent place among transition metals, recognised for its strength and versatile applications. With an atomic number of 40, it is positioned in the periodic table as a metal with high resistance to corrosion and excellent strength at elevated temperatures.

Discovered in the late 18th century by chemists such as Martin Heinrich Klaproth, zirconium has since become a subject of scientific interest due to its distinctive physical and chemical behaviour. Its natural occurrence is mostly in the form of zircon, a zirconium silicate mineral, which serves as the primary source for its extraction.

Chemical Properties Description

The chemical behaviour of zirconium is marked by its strong resistance to corrosion and its ability to form stable compounds. In most applications, zirconium exists in a +4 oxidation state, which contributes to its formation of a thin yet protective oxide layer when exposed to air. This layer prevents further oxidation and degradation, making zirconium ideal for environments where chemical stability is paramount.

The element reacts with oxygen, water, and acids under controlled conditions to form compounds that have diverse applications. Its reactivity with halogens, for example, produces zirconium tetrachloride, a precursor in various industrial processes. Zirconium's chemical inertness is also reflected in its minimal interaction with most acids and bases, further underlining its durability. These characteristics are essential in contexts where reliability and longevity of materials are required, such as in nuclear reactors or high-performance aerospace components.

Physical Properties Data Table

|

Property |

Value |

|

Atomic Number |

40 |

|

Atomic Weight |

~91.22 |

|

Melting Point |

1855 °C |

|

Boiling Point |

4409 °C |

|

Density |

6.52 g/cm³ |

|

Crystal Structure |

Hexagonal (α-phase) |

|

Thermal Conductivity |

~22.6 W/m·K |

For more information, please check Stanford Advanced Materials (SAM).

Common Uses

Zirconium's unique properties have paved the way for its incorporation into a variety of practical applications. One of its most notable uses is in the nuclear industry, where its low neutron absorption rate makes it an ideal cladding material for fuel rods. The stability of zirconium under intense radiation and high temperatures ensures safe and efficient operation in nuclear reactors.

Zirconium finds common uses in the chemical processing industry. Its corrosion resistance is exploited in the production of heat exchangers, valves, and piping systems, where long-term durability is essential. The metal is also used in the aerospace sector due to its high strength-to-weight ratio and excellent performance in high-temperature environments.

In addition, zirconium compounds such as zirconium dioxide (zirconia) are widely utilised in ceramics, dental implants, and refractory materials. These applications not only highlight the versatility of zirconium but also its ability to meet rigorous industrial standards.

Preparation Methods

The production of zirconium for industrial applications involves several careful preparation methods to ensure its purity and desirable properties. The extraction process begins with the mining of zircon, the primary mineral source of zirconium. Once extracted, the mineral undergoes a series of refining procedures that remove impurities and convert it into a usable form.

Frequently Asked Questions

What is zirconium's role in the nuclear industry?

Zirconium is valued in nuclear reactors because its low neutron-capture cross-section makes it an ideal cladding material for fuel rods.

What are the main chemical properties of zirconium?

Zirconium exhibits strong corrosion resistance, a high oxidation state (typically +4), and forms a self-healing protective oxide layer on its surface.

How is zirconium typically prepared for industrial use?

Zirconium is extracted from its primary ore, zircon, and then refined through processes such as chlorination and controlled reduction to obtain pure metal.

In which industries is zirconium most commonly used?

It is widely applied in nuclear energy, aerospace, chemical processing, and even dental and medical applications due to its stability and durability.

What are some related industrial products derived from zirconium?

Products include zirconium alloys for high-performance applications, zirconium dioxide ceramics for dental and refractory uses, and zirconium carbide for cutting tools.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

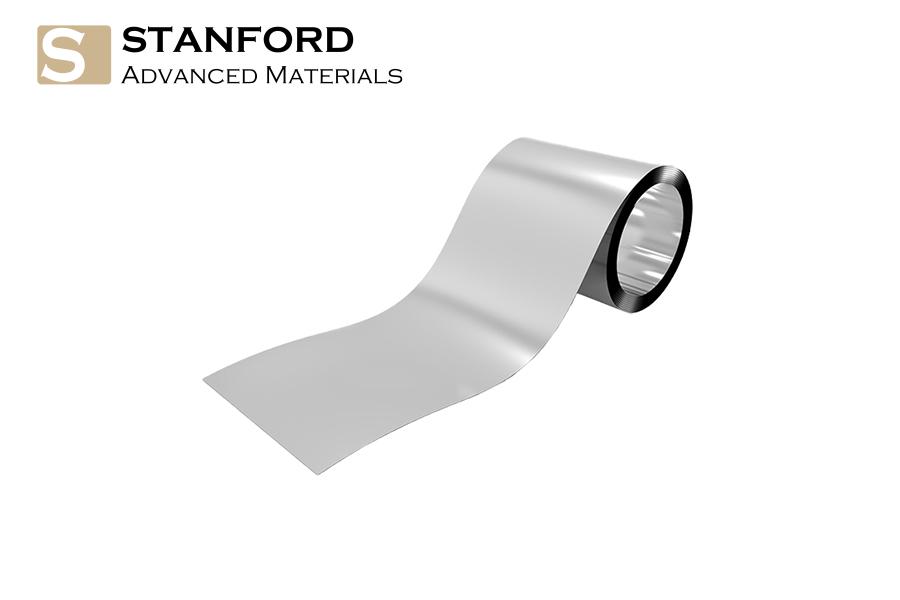

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento