Overview Of The Corrosion Resistance Of Common Special Metal Materials

Special metal materials, with good corrosion resistance and mechanical processing performance, can greatly meet the requirements of factory production equipment corrosion resistance and improve the equipment corrosion resistance grade. The following is an overview of the corrosion resistance of common special metal materials.

Titanium Material

Titanium is a metal with a strong passivating tendency. In the air and oxidising or neutral aqueous solutions, a stable protective oxide film can be formed rapidly and automatically, even if the film is damaged for some reasons. Therefore, titanium has excellent corrosion resistance in the oxidising and neutral medium. Due to its substantial passivating properties, titanium itself does not accelerate the corrosion when it comes into contact with heterogeneous metals in many cases but may accelerate the corrosion of heterogeneous metals. For example, when Pb, Sn, Cu or monel alloy contacts with titanium to form an electric couple in a low concentration of non-oxidising acid, the corrosion of these materials is accelerated, while titanium is not affected.

The iron content in titanium affects the corrosion resistance of some media. In addition to raw materials, the increase in iron content is often due to contamination from iron infiltration during welding, which raises the iron levels in the weld. As a result, corrosion becomes uneven in nature. It is almost inevitable that iron contamination on the titanium contact surface will accelerate in the iron contamination area, especially in the presence of hydrogen. When the titanium oxide film on the stained surface causes mechanical damage, hydrogen seeps into the metal. According to temperature, pressure and other conditions, hydrogen diffuses accordingly, which makes titanium produce different degrees of hydrogen embrittlement. Therefore, titanium should avoid surface iron contamination when used in medium temperature and pressure and hydrogen-bearing systems.

Nickel and Nickel-based Alloys

Nickel has a large tendency to become blunt. At ordinary temperatures, the surface of nickel is covered with an oxide film, which makes it resistant to corrosion in water and many saline solutions.

Nickel is fairly stable at room temperature in non-oxidising dilute acids, such as < 15% hydrochloric acid, <17% sulphuric acid and many organic acids. However, the corrosion rate of nickel significantly increases with the increase of oxidants (FeCl2, CuCl2, HgCl2, AgNO3, and hypochlorite) and ventilation.

Nickel is completely stable in all alkali solutions, either at high temperature or molten base, which is the outstanding characteristic of nickel.

Monel alloy is more corrosion resistant than nickel in reducing medium and copper in the oxidising medium, and it is very resistant to corrosion as soon as oxygen enters in any hydrofluoric acid concentration. However, its hydrofluoric acid resistance declines when there is aeration and oxidiser in the solution, or when there are some harmful impurities such as iron salt or copper salt in the solution. In addition to platinum and silver, monel alloy is one of the best materials to resist hydrofluoric acid corrosion.

Cupronickel

The corrosion resistance of cupronickel is analogous to that of pure copper, and serious corrosion will occur in inorganic acids, especially in nitric acid. But for hydrofluoric acid with a concentration of less than 70%, it is resistant to corrosion in the absence of oxygen and below the boiling point. Besides, cupronickel is less corrosive inorganic acids, alkaline solutions the and organic compounds.

In caustic soda, or in diaphragm electrolytic caustic soda, B30 (70-30 copper-nickel alloy) can be used instead of pure nickel to produce film evaporator equipment, especially film following parts, which will not only improve the service life but also save 70 per cent of nickel. In addition, B10 (91-9 Cu/Ni alloy) can also replace pure nickel to produce the evaporator's evaporator tube and evaporator equipment. Moreover, cupronickel has high resistance to corrosion in seawater, so the heat exchanger cooled by seawater usually uses cupronickel of B10 and B30.

Zirconium

Zirconium has better corrosion resistance than stainless steel, nickel base alloy and titanium. Its mechanical and technological properties are also suitable for the manufacture of containers and heat exchangers.

Zirconium was rarely used in industrial production because of its high price. However, with the development of the domestic chemical industry, zirconium materials are increasingly used in many of the equipment with strong corrosion, which greatly improves the service life and reliability of the equipment and achieves better economic benefits. At present, the technology has become increasingly mature from the production of zirconium to the design, manufacture, and inspection of equipment, providing a foundation for the wide application of zirconium containers.

Tantalum

Tantalum has high chemical stability, chemical resistance and atmospheric corrosion under 150 °C. It is corrosion resistant even in the pollution of the industrial atmosphere. Tantalum exhibits high stability in both acidic and alkaline environments at temperatures up to 200°C, surpassing the stability of gold and platinum.

Tantalum is not corrosion-resistant in concentrated lye. It is not resistant to potassium iodide and the solution containing fluorine ions. The corrosion of tantalum is uniform and comprehensive corrosion, which is not sensitive to the incision and does not occur in local corrosion, such as corrosion fatigue and corrosion cracking. This characteristic of tantalum can be used as coating and lining materials.

Metal Composite Material

Although special metal materials have better corrosion resistance, they are also relatively expensive, which is one of the reasons why they cannot be widely used. However, metal composite technology promotes the application of these special metal materials from another aspect.

The metal composite material is a new metal material which is composed of several metals or alloy elements such as a, b, c, etc. Metal bonds formed on the surface of all walks of life combine to make the metal composites have the same or better properties of the original monomer metal materials. It is neither a nor b (or c). It combines the advantages of constituent components and overcomes the performance shortfalls of a single component. Metal composite material not only optimises material design but also embodies the principle of reasonable use of materials.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

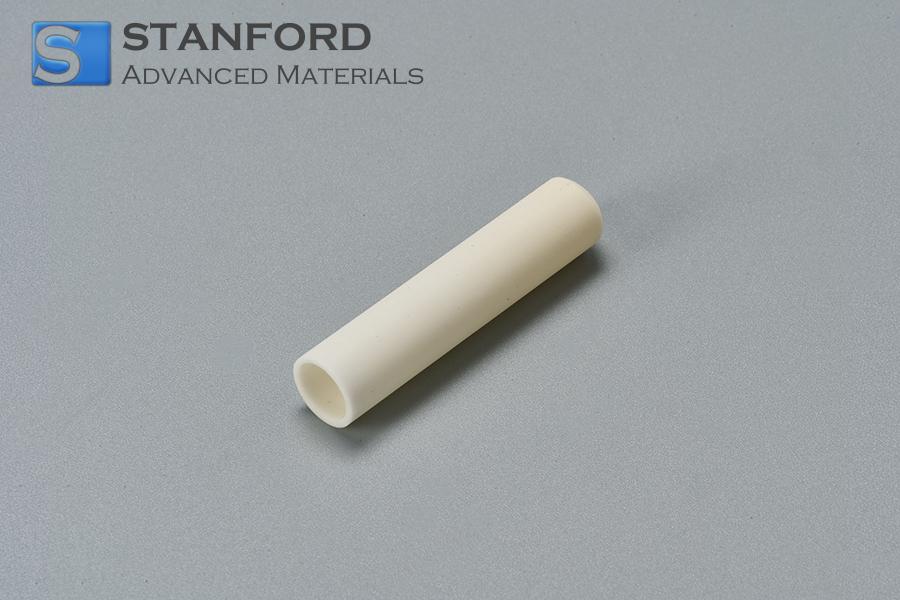

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento