Applications Of Niobium Oxalate In Fine Functional Materials

Introduction to the Pillars of Modern Civilisation

In the system of factors advancing modern civilisation, three pillars assume primary importance: energy, information and materials. In this context, materials serve as the foundation and support measured advancements in technology and innovation. In-depth study of materials science can enhance individual sectors and the overall structure of our technological civilisation.

Functional materials, defined by properties such as light, electricity, magnetism, sound, heat or biological interactions, play a key role in driving progress in a variety of fields. They are used in energy production, computer technology, communication, electronics, laser systems, space research and medicine. Their development and application cover a broad range of human endeavour.

Recent scientific research has identified a material from extensive studies that has gained importance: Niobium Oxalate. This article assesses the role of Niobium Oxalate in the domain of fine functional materials and reviews its applications, impact and potential for future use.

The Role of Tantalum-Niobium in Functional Materials

Tantalum and niobium, elements initially given limited attention in the periodic table, have become significant in functional materials. They evolved from laboratory subjects to important components in various technological applications. In the field of fine functional materials – which includes conductive ceramics, dielectric ceramics, ferroelectric ceramics and ferrites – tantalum-niobium contributes to material properties through quantifiable improvements.

The use of tantalum-niobium extends to conversion materials such as thermoelectric, piezoelectric, pyroelectric and photoelectric materials. In each case, the incorporation of tantalum-niobium improves energy conversion processes, thereby increasing process efficiency by measurable margins.

In addition, tantalum-niobium is applied in the production of functional film materials – including optical thin films, magnetic thin films, conductive films and dielectric films – which support improvements in solar cell efficiency and the storage capacity of magnetic media. Its contribution is observed across a range of technological systems.

In the area of catalytic materials, tantalum-niobium aids in chemical reactions by enhancing precision and reducing energy consumption. This property is of particular value for industries seeking environmentally friendly processes.

The multiple applications of tantalum-niobium in fine functional materials illustrate the importance of elemental research in advancing technology. Continued investigation into these elements provides practical solutions to current technical challenges and supports the development of future technology.

Niobium Oxalate: A Versatile Compound

Among the many applications of tantalum-niobium, Niobium Oxalate emerges as a versatile compound. As a soluble niobium compound, it offers measurable benefits in the manufacture of functional materials. Its ability to form uniform mixtures with other compounds adds to its usefulness in controlled processing.

Niobium Oxalate is significant as a precursor because of its solubility and ability to produce homogeneous mixtures. It is used as a catalyst precursor in chemical reactions, as a base compound in the manufacture of dielectric materials, in the development of ferrites and may be converted into niobium pentoxide for additional applications. Its compatibility with other materials enables the synthesis of compounds that benefit from the quantitative properties of niobium.

An examination of specific applications of Niobium Oxalate reveals a significant contribution to the field of fine functional materials. Its role in initiating reactions in a wide range of technology systems supports various scientific improvements.

Applications of Niobium Oxalate

An overview of the specific applications of Niobium Oxalate indicates that it has the potential to improve fine functional materials across several sectors.

Catalyst

In catalysis, Niobium Oxalate is used as an important precursor for the production of catalysts based on niobium oxide. These catalysts utilise the measurable properties of niobium in various chemical processes. Niobium functions as an active catalytic phase in catalysts, thereby optimising reaction pathways and increasing both efficiency and selectivity. The solubility of Niobium Oxalate facilitates its combination with other metal compounds, consequently yielding catalysts that are more reactive and stable under diverse conditions. This capability is important for industries that focus on environmentally friendly chemical processes.

Dielectric Materials

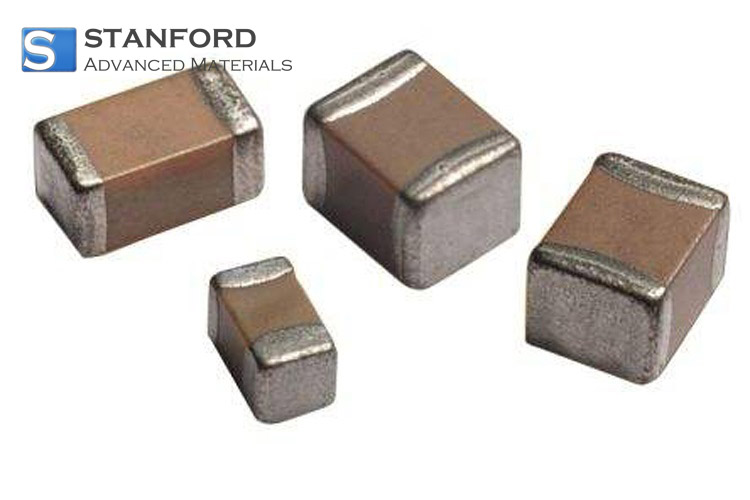

Niobium Oxalate is employed as a precursor for Niobium Oxide, a component required for the manufacture of high-performance dielectric materials. Conversion of Niobium Oxalate into Niobium Oxide at relatively low temperatures, combined with its water solubility, ensures a uniform distribution of niobium within the material matrix. Such even distribution is essential for minimising electrical losses and maximising magnetic conductivity, thereby improving the performance of electronic components. These advancements in dielectric materials contribute to the reduction in size and weight of electronic devices.

Ferrite

In the development of ferrites, the contribution of Niobium Oxalate is significant. The addition of niobium ions, obtained from water-soluble Niobium Oxalate, improves performance by reducing energy loss at high frequencies. This improvement is critical for applications in electronics and communication technology, where ferrites are used in transformers, inductors and magnetic cores. The ability of Niobium Oxalate to promote material uniformity and enhance magnetic properties is valued in the production of more efficient and reliable components.

These applications demonstrate that Niobium Oxalate contributes to the enhancement of fine functional materials. Its use in improving the properties of catalysts, dielectric materials and ferrites supports the advancement of current technologies. Continued research into Niobium Oxalate promises new opportunities in materials science.

Challenges and Future Research Directions

Despite the promising applications and potential of Niobium Oxalate in fine functional materials, several challenges impede its widespread adoption in industrial processes. One major issue is the scalability of production techniques. Although Niobium Oxalate offers advantages in laboratory settings, scaling up production to meet industrial demand presents technical and economic challenges. The costs associated with synthesising high-purity Niobium Oxalate and integrating it into manufacturing processes remain significant; further research is needed to develop more cost-effective and efficient production methods.

Another challenge is the optimisation of incorporating Niobium Oxalate into functional materials. Achieving the desired distribution and concentration of niobium requires strict control of synthesis and processing conditions. Such control is essential for fully utilising Niobium Oxalate to enhance the properties of catalysts, dielectric materials and ferrites. Researchers must continue to develop new methods for adjusting the structure and composition of materials based on Niobium Oxalate, thereby enabling additional functionalities.

Future research directions for Niobium Oxalate in functional materials are extensive. Collaboration among chemists, materials scientists, engineers and industry professionals is necessary to address the current challenges and to fully exploit its potential. Areas of special interest include the development of environmentally friendly synthesis methods, investigation of its applications in renewable energy technologies and assessment of its potential in fields such as nanotechnology and biomedicine.

Conclusion

Niobium Oxalate plays an important role in materials science by supporting the development of fine functional materials with improved properties. Its applications in catalysts, dielectric materials and ferrites contribute to technological progress and assist in addressing current industrial challenges. However, realising its full potential requires dedicated efforts to overcome issues related to scalability and integration into existing manufacturing methods.

As research on Niobium Oxalate continues to clarify its potential in materials science and sustainable technologies, collaboration with leading suppliers such as Stanford Advanced Materials (SAM) becomes increasingly important. Their provision of high-quality Niobium Oxalate and related materials is crucial for closing the gap between laboratory research and industrial application, thereby ensuring that improvements in material performance benefit a wider range of technological applications.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento