Applications Of Polytetrafluoroethylene (PTFE) In Medical Treatments

Various types of polymer products are widely used in modern medicine. These products are employed in contact with human tissue and in diverse medical devices. In recent years, polymers have replaced metal and other materials in medical applications. This article discusses the use of PTFE in this field, which is the most frequently used material among fluorinated plastics.

It is generally recognised that polymer products in medicine can be categorised into three groups.

The first group comprises products that enter the body either permanently or temporarily. Polymer products that remain permanently in biological systems include implants, such as artificial substitutes for tissues and organs. Polymer products for temporary application include catheters, drainage tubes, stethoscopes, filters and air conditioning units. They are primarily used for the transport of substances and gases and for the filtration of media.

The second category comprises products that are used externally. Essential properties of polymers include plasticity, light weight, strength, sealing capability, elasticity, resistance to corrosive media and electrical insulation. Examples include gloves, compression cuffs, devices for limb fixation and enclosures for diagnostic equipment.

The third category comprises functional components in devices used for biochemical analysis and synthesis. Examples include apparatus for cell and tissue culture, as well as systems for regeneration and proliferation.

In the first category, fluorocarbon has been most frequently utilised. The in vivo application of fluoroplastics depends on properties such as inherent biological inertness and the capacity to form pores after specialised treatment. This inertness is exploited to manufacture implants that are not rejected by the body and to develop devices that contact blood without causing damage.

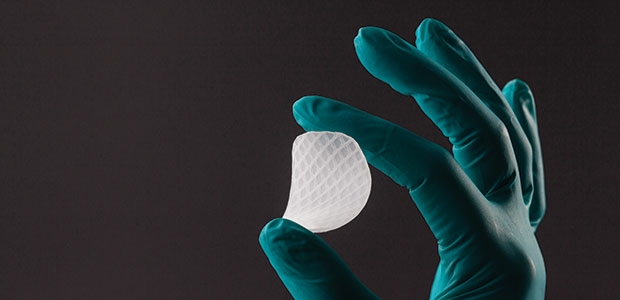

If necessary, the porous structure of PTFE can serve as a forming matrix for organic cells and tissues. Its defined diameter, porosity and surface micro-relief allow directed cell growth in the polymer structure, thereby enabling the restoration of lost function in an organ or tissue. For example, this method is applied in the treatment of arteriosclerosis and in vascular replacement, addressing one of the most common diseases encountered today.

PTFE products have been present in both domestic and international medical markets for more than 30 years. They are used in all surgical fields and are extensively employed in the production of transplants. Low raw material consumption, relatively straightforward processing and high product prices have resulted in a high profit margin in the manufacture of medical products.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento