How Can Nitinol Make A Sprinkler Switch On

A nickel–titanium alloy, also known as Nitinol, is a binary alloy composed of nickel and titanium. The two elements exhibit approximately equal atomic percentages (Nitinol 55 and Nitinol 60 are common). Due to temperature variations and mechanical stress, Nitinol displays two distinct crystal structure phases, namely the austenitic phase and the martensitic phase.

In Nitinol, the austenite is the parent phase. It is the crystal structure at elevated temperatures. When the temperature decreases, austenite gradually converts into martensite.

During the conversion from martensite to austenite, four temperature definitions are used:

As: the temperature at which conversion from martensite to austenite begins during heating.

Af: the temperature at which conversion from martensite to austenite completes during heating.

Ms: the temperature at which conversion from austenite to martensite begins during cooling.

Mf: the temperature at which conversion from austenite to martensite completes during cooling.

The phase transformation exhibits thermal hysteresis; consequently, As does not equal Mf, and similarly, Af does not equal Ms.

Nitinol exhibits two properties: the shape memory effect (SME) and superelasticity (SE).

1. Shape Memory

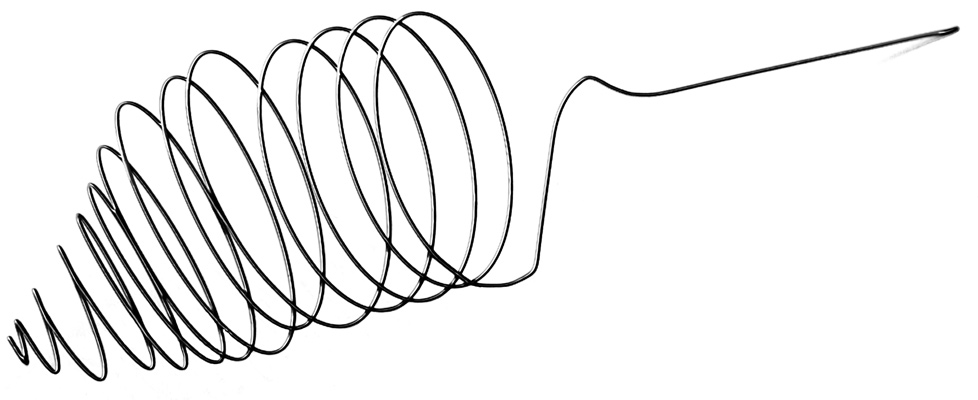

When the parent phase, in a specific shape, is cooled from a temperature above Af to one below Mf, it completely transforms into martensite. Martensite becomes deformed below Mf. When reheated to a temperature below Af, the material reverts to the parent phase by phase reversion. This process is a thermally induced phase transition in Nitinol. Nitinol can be deformed at a defined temperature and recovers its original, undeformed shape when heated above its transition point.

2. Superelasticity

Superelasticity refers to the phenomenon in which an external force induces strain exceeding the elastic limit. Upon removal of the load, the strain recovers automatically. In the parent phase, external stress triggers a transformation to martensite. This alloy exhibits mechanical behaviour that differs from that of conventional materials. Its elastic limit is higher than that of ordinary materials. Hooke’s law becomes inapplicable in this regime. Unlike the shape memory effect, the superelastic response does not require thermal input.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento