How Is Tantalum Found

What is Tantalum?

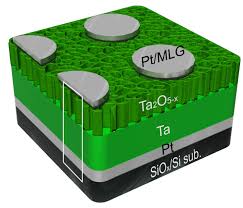

Tantalum is a metal element with the element symbol Ta and atomic number 73. It has a density of 16.68 g/cm³ and a melting point of 2980 °C. It is the third highest refractory metal. Pure Tantalum exhibits a blue colour and ductility. It can be cold rolled into very thin sheets without intermediate annealing. Its corrosion resistance is comparable to that of glass. At approximately 150 °C, only fluorine, hydrofluoric acid, sulphur trioxide, alkali and certain molten salts affect it. At room temperature, Tantalum remains stable. When heated to 500 °C, oxidation to Ta2O5 accelerates.

What are the Properties of Tantalum?

Tantalum has several properties, including a high melting point, low vapour pressure and capacity for cold processing. It possesses chemical stability and resists corrosion, and it forms a liquid metal oxide film. It is used in electronics, metallurgy, the chemical industry, iron and steel production, hard alloys, nuclear energy, superconducting technology, automotive electronics, aerospace, medical technology and scientific research. The primary application of Tantalum is in Tantalum capacitors. Tantalum is usually found together with Niobium, which has similar chemical characteristics. They typically occur in niobium‐tantalum ore, iron ore and coltan. Brazil and Australia have the largest Tantalum reserves.

History of the Discovery of Tantalum

During the eighteenth century a dense black mineral was discovered in North America and sent to the British Museum. Approximately 150 years later, in 1801, British chemist C. Hatchett analysed the ore at the museum. He discovered a new element and named it Columbium, referring to early mineral deposits in Columbia.

In 1802, Swedish chemist A.G. Ekaberg analysed a mineral in Scandinavia. Its acidic fluoride salt underwent recrystallisation. This process led to the discovery of a new element, which he named Tantalum after Tantalus from Greek mythology.

Because of the similar chemical characteristics of Columbium and Tantalum, they were initially considered to be the same element. In 1809, British chemist William Hyde Wollaston compared Tantalum oxide and Columbium oxide. Although their densities differed, he believed they were identical.

In 1844, German chemist Heinrich Rose rejected the idea that Tantalum and Columbium were identical. He employed chemical methods and determined that they are two separate elements. He named them Niobium and Pelopium.

In 1864, Christian Wilhelm Blomstrand and Louis Joseph Troost demonstrated that Tantalum and Niobium are distinct chemical elements. They also established the chemical formulae of several related compounds. Early Tantalum metal contained more impurities. In 1903, Werner von Bolton produced pure Tantalum metal for the first time.

Scientists initially used a hierarchical crystallisation method to separate Tantalum from Niobium. De Marinella developed this method in 1866. Today, scientists use a solvent extraction method for the fluoride‐containing solution.

Development of the Tantalum Industry

Tantalum was discovered in the early nineteenth century, but industrial production began in 1903. Consequently, the global Tantalum industry started developing in the 1920s.

The United States was the first country to produce Tantalum. In 1922, it produced Tantalum metal on an industrial scale. Japan and other countries began developing their Tantalum industries in the late 1950s. Over several decades, production levels increased. The products, technology and equipment meet the requirements for supporting global scientific and technological progress.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento