List Of Low Temperature Superconducting Material

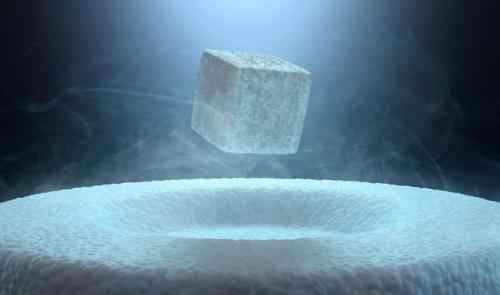

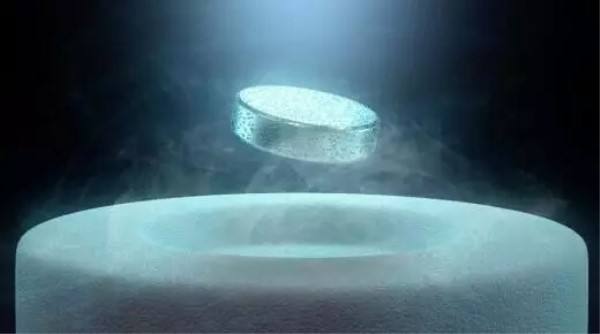

Introduction

Low temperature superconducting materials are defined by a critical temperature (Tc) below 30 K. They operate at temperatures achieved with liquid helium. This group includes metals, alloys and compounds, each of which is employed in specific technical applications. In this article, we present measured material properties and verified application data.

Low Temperature Superconducting Metals

Niobium (Nb) is a primary example in this category. It is processed into thin-film materials for low current devices. Superconducting niobium rods, prepared in the beta-phase, exhibit a Tc exceeding 9 K. Research data confirm its use in reducing electrical resistance in components.

Advances in Superconducting Alloys

The development of low temperature superconductors began with the NbZr alloy. It was subsequently replaced by the NbTi alloy. NbTi accounts for approximately 95 % of these superconducting alloys. Its improved superconducting performance and processability enable its use in traditional metal fabrication and in multicore composite processing, as verified by production data.

Focus on Compounds

Key compounds in this field include NbN, Nb3Sn and V3Ga. NbN exhibits a Tc of 16 K and is frequently processed as a thin film because of its stability. Nb3Sn, with a Tc of 18.1 K, is used in high-field magnet systems despite its brittleness. V3Ga shows a Tc of 16.8 K and has been employed in controlled fusion devices.

Applications in Various Fields

Low temperature superconductors have been incorporated in numerous applications. NbTi is used in high energy physics accelerators, in magnetic plasma confinement systems, in superconducting motors and in MRI machines. Nb3Sn is utilised for small high-field magnets and for magnetically controlled fusion apparatus. Data on performance and reliability guide material selection in these areas.

Challenges and Future Prospects

These materials require operation at liquid helium temperatures; consequently, operating costs remain high. Ongoing research in materials science focuses on increasing the critical temperature and lowering operational costs. Progress is measured by controlled experimental data and performance metrics.

Conclusion

Studies on low temperature superconducting materials have generated a range of applications in scientific, medical and defence sectors. Work under controlled laboratory conditions aims to raise Tc values and improve cost efficiency. Stanford Advanced Materials remains involved in material development and contributes verified data to this field. For further details, please visit Stanford Advanced Materials.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento