What Are The Ceramic Materials With High Thermal Conductivity?

The thermal conductivity of ceramic materials plays an important role in their application. Increasing the thermal conductivity by specific methods enhances heat conduction, heat convection and thermal radiation, thereby extending the range of applications. Ceramic materials with high thermal conductivity are mainly composed of oxides, nitrides, carbides and borides, for instance polycrystalline diamond ceramics, aluminum nitride, beryllium oxide, silicon nitride and silicon carbide.

Polycrystalline Diamond (PCD)

Diamond exhibits high thermal conductivity. The theoretical thermal conductivity of a single crystal is 1 642 W/m-K at room temperature, and the measured value is 2 000 W/m-K. However, large single crystal diamond is difficult to produce and expensive. During the sintering of polycrystalline diamond, sintering additives are often introduced to strengthen the bonding between the diamond powders, thereby obtaining PCD ceramics with high thermal conductivity. The sintering additive may catalyse the carbonisation of the diamond powder at high sintering temperatures, which results in the polycrystalline diamond no longer being isolated. Small single crystal diamond is frequently added as a reinforcement to conductive ceramics in order to improve the thermal conductivity.

Polycrystalline diamond ceramics are used in technical and functional applications. They are employed in modern industry, national defence and advanced technology sectors because they satisfy requirements pertaining to mechanical, thermal, chemical, acoustic, optical and electrical properties.

Silicon Carbide

At present, silicon carbide (SiC) is widely regarded as an active heat-conducting ceramic material both domestically and internationally. Its theoretical thermal conductivity is very high, reaching 270 W/m-K. Given that the ratio of surface energy to interface energy in SiC ceramics is low – in other words, the grain boundary energy is high – it is difficult to manufacture high-purity and dense SiC ceramics using conventional sintering methods. When conventional sintering procedures are applied, sintering additives must be used and the sintering temperature raised above 2 050 ℃. Consequently, these conditions promote grain growth and significantly reduce the mechanical properties of SiC ceramics.

Silicon carbide ceramics are applied in high-temperature bearings, ballistic plates, nozzles, corrosion-resistant high-temperature components, high-temperature and high-frequency parts of electronic devices and various other fields.

![]()

Silicon Nitride

Researchers both domestically and internationally have increasingly investigated silicon nitride ceramics (Si3N4) as a consequence of its high toughness, high thermal shock resistance, effective insulation, corrosion resistance and non-toxicity. The bond strength, average atomic mass and anharmonic vibrations of silicon nitride ceramics are comparable to those of SiC. The theoretical thermal conductivity of silicon nitride crystals is in the range of 200 to 320 W/m-K. Given that the structure of Si3N4 is more complex than that of aluminum nitride (AlN) and that phonon scattering is greater, the thermal conductivity of sintered Si3N4 ceramics in the present study is considerably lower than that of Si3N4 single crystals, thereby limiting its application.

![]()

Beryllium Oxide

Beryllium oxide (BeO) possesses a hexagonal wurtzite structure with a small interatomic distance between Be and O atoms, a low average atomic mass and dense atomic packing. These characteristics fulfil the conditions of the Slack model for high thermal conductivity in a single crystal. In 1971, Slack and Auaterrman measured the thermal conductivity of BeO ceramics and a large BeO single crystal, and calculated that the thermal conductivity of the large BeO single crystal could reach up to 370 W/m-K. Presently, manufactured BeO ceramics can achieve a thermal conductivity of 280 W/m-K, which is approximately ten times higher than that of aluminium oxide (Al2O3) ceramics.

Beryllium oxide is used in aerospace, nuclear energy, metallurgy, electronics and rocket construction. BeO is often employed as carrier components and assemblies in avionics conversion circuits and in aircraft and satellite communication systems; BeO ceramics offer high thermal shock resistance and may be utilised in the fire tubes of jet engines; metal-coated BeO plates have been implemented in the control systems of aircraft engine devices; Ford and General Motors use metal-sprayed beryllium oxide linings in automobile ignition systems; and BeO, owing to its good thermal conductivity and ease of miniaturisation, is applicable in the laser field. For example, BeO lasers operate with a higher efficiency and produce a greater output power than quartz lasers.

Aluminium Nitride (AlN)

Aluminium nitride ceramics are the most frequently used materials with high thermal conductivity. The theoretical thermal conductivity of aluminium nitride single crystals can reach 3 200 W/m-K. Due to inevitable impurities and defects during the sintering process, these contaminants generate various defects in the AlN lattice that reduce the average phonon mean free path, thereby greatly lowering the thermal conductivity. In addition, the grain size, morphology and the content and distribution of the secondary phase at the grain boundaries exert important effects on the thermal conductivity of AlN ceramics. Larger grain sizes lead to a greater average phonon mean free path, and consequently, higher thermal conductivity in sintered AlN ceramics.

As a typical covalent compound, aluminium nitride has a high melting point, a low atomic self-diffusion coefficient and high grain boundary energy during sintering. Consequently, producing high-purity AlN ceramics with conventional sintering methods is challenging. Moreover, the addition of suitable sintering aids can react with the oxygen in the lattice to form a secondary phase, thereby purifying the AlN lattice and improving its thermal conductivity.

Common sintering aids for AlN ceramics include yttrium oxide (Y2O3), calcium carbonate (CaCO3), calcium fluoride (CaF2) and ytterbium fluoride (YF3). At present, aluminium nitride ceramics with high thermal conductivity are being thoroughly investigated with the addition of appropriate sintering aids both domestically and internationally, and ceramics with a thermal conductivity of up to 200 W/m-K have been produced. However, production costs are high owing to the extended sintering duration, high sintering temperature and the cost of high-quality AlN powder.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

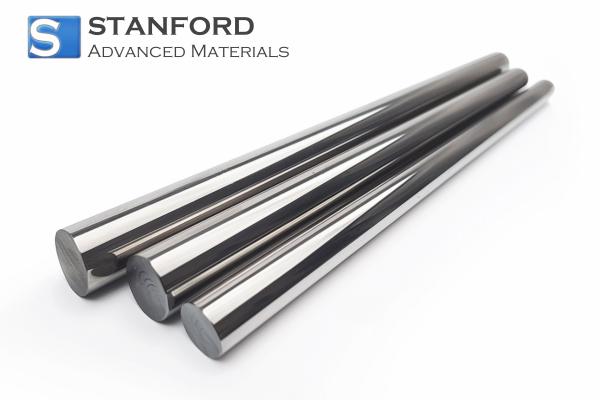

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento