Filter Foam Fundamentals: Making The Right Choice

Introduction

Within the field of filtration, the choice of material significantly affects system efficiency and effectiveness. Among the available options, filter foam has been shown to meet a range of technical filtration requirements.

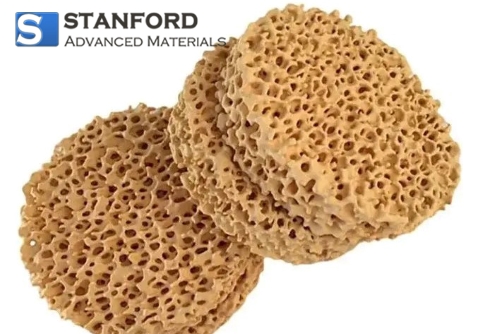

Figure 1. Various Foam Filters

This document explains the fundamentals of filter foam. It is intended to provide technical information that assists in selecting foam products tailored to specific requirements.

Understanding Filter Foam

Filter foam is a porous material produced specifically for filtration purposes. Its structure is defined by a network of cells that may be either open-celled or closed-celled.

lOpen-Cell Structure: In open-cell foam, cells interconnect to form an open network. This structure allows air, water and other substances to pass with minimal resistance, making it suitable for applications that require high permeability.

lClosed-Cell Structure: Closed-cell foam contains discrete cells that do not interconnect. This structure results in a firmer and less permeable material, which is required for applications where moisture resistance and structural integrity are essential.

Types of Filter Foam

Filter foam is categorised by the material from which it is produced. Each type exhibits specific properties and is used for defined filtration tasks across various industries. The selection of material determines key parameters such as density, porosity, chemical resistance and thermal characteristics.

Below is a detailed overview of common types of filter foam:

1. Polyurethane Foam:

- Description: Polyurethane foam is an open-cell foam that is manufactured in various densities and porosities. It can be produced to meet a range of filtration specifications.

- Applications: It is used for air and water filtration in HVAC systems, automotive filters and consumer products, as it captures particulate matter while permitting fluid flow.

2. Reticulated Foam:

- Description: This foam type possesses a very open cell structure that ensures high permeability for air and water. It exhibits chemical resistance and mould inhibition, which is important in selected filtration processes.

- Applications: Reticulated foam is used in industrial air filters, aquarium filters, pre-filtration units in HVAC systems and cleaning applications.

3. Polyethylene Foam:

- Description: Polyethylene foam is a closed-cell foam noted for its rigidity, buoyancy and resistance to moisture and chemicals. Its structure provides durability and sufficient strength for many uses.

- Applications: It is employed in water filtration systems, packaging, flotation devices and sports equipment, where water resistance and structural integrity are required.

4. Activated Carbon Foam:

- Description: This foam is designed to filter gases, odours and chemical fumes through adsorption. It combines the physical filtration characteristics of foam with the adsorptive capacity of activated carbon.

- Applications: Activated carbon foam is used in air purifiers, odour control systems and industrial gas filtration, where it binds a variety of airborne contaminants.

5. Ceramic Foam:

- Description: Ceramic foam is a porous material that withstands elevated temperatures. It is produced for high-temperature applications as its structure permits efficient filtration under such conditions.

- Applications: Standard uses include the filtration of molten metal, hot gas filtration and serving as a catalyst support in industrial processes. On our website a range of ceramic foams is listed (see Table 1).

Figure 2. Zirconia Ceramic Foams

Table 1. Ceramic Foam Products

|

Type of Ceramic Foam |

Applications |

Key Properties |

|

Filtration, Catalyst Support |

High temperature resistance, adequate mechanical strength |

|

|

Thermal insulation, furnace linings and filters during metal casting |

High thermal stability, high melting point |

|

|

Filtration of molten metal, flame retardant |

High thermal conductivity, low thermal expansion |

|

|

Thermal insulation, fire-resistant material |

High heat resistance, corrosion resistance |

6. Metal Foam:

- Description: Metal foam is composed of metallic elements and features a porous structure with a high strength-to-weight ratio. It is produced from various metals including aluminium, copper and nickel, each offering distinct properties.

- Applications: Metal foam is used in high-temperature filtration, heat exchangers, energy absorption and certain aerospace applications. SAM provides an extensive range of metal foams, as detailed in Table 2.

Figure 3. Titanium Metal Foams

Table 2. Metal Foam Products

|

Type of Metal Foam |

Common Applications |

Description |

|

Automotive components, aerospace, architectural applications |

Low density, stable, good thermal conductivity |

|

|

Batteries, filtration, heat exchangers |

High electrical conductivity, large surface area |

|

|

Catalyst support, energy storage |

High mechanical strength, corrosion resistance |

|

|

Structural components, acoustic insulation |

High strength-to-weight ratio, effective shock absorption |

|

|

Chemical processing, medical devices |

Very high corrosion resistance, biocompatibility |

|

|

Medical implants, orthopaedic applications |

Biocompatible, high corrosion resistance |

7. Electrostatic Foam:

- Description: This foam utilises static electricity to attract and capture dust and fine particles. It has been found to be effective for the filtration of fine dust.

- Applications: Electrostatic foam is typically used in HVAC filters, air purifiers and cooling systems for electronic devices, where the capture of small particles is critical.

Choosing the Appropriate Filter Foam

When selecting the appropriate filter foam, several factors must be considered:

1.Filtration Requirements: Determine the particle size that requires filtration. Smaller particles necessitate foam with increased porosity.

2.Environmental Conditions: Evaluate the operating environment. Foam that is exposed to high temperatures or corrosive substances must possess specialised material properties.

3.Durability and Maintenance: Consider the expected lifespan and maintenance requirements. Foams with longer lifespans may incur higher initial costs yet result in reduced long-term maintenance effort.

4.Compliance and Standards: Ensure that the foam meets the applicable industry standards and certifications.

Conclusion

Choosing the appropriate filter foam is a critical decision as it directly influences the efficiency and cost-effectiveness of the filtration system. Filter foams are produced in various materials such as polyurethane, reticulated, polyethylene, activated carbon, ceramic, metal and electrostatic types. Their applications include air and water filtration, acoustic insulation, odour control and high-temperature processing.

Stanford Advanced Materials (SAM) is recognised for its expertise in the manufacture and supply of filter foams that meet specific technical requirements. On our website, an extensive range of metal and ceramic foams is available. Further technical details regarding foam materials can be found on our homepage.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento