Case Study: Silicon Carbide Plates For Advanced Armor Solutions

Introduction

In today's continually developing defence and security environment, the primary task is to protect personnel and assets from current threats. Silicon Carbide Plates are known for their high hardness and durability and are used in the production of armour solutions. This article explains the role of these plates in improving defence strategies, safeguarding lives and reinforcing military facilities.

Figure 1. The Defence Industry [1]

Understanding Silicon Carbide Plates

Silicon Carbide (SiC) plates are a type of protective material used in defence and military applications. They are engineered to counter various threats, including ballistic projectiles, high-velocity fragments and chemical substances.

They are typically produced from a composite that combines Silicon Carbide ceramic with other materials such as boron carbide or high-strength fibres like aramid (e.g. Kevlar) or ultrahigh-molecular-weight polyethylene (UHMWPE). The SiC ceramic component provides measurable hardness and resistance against ballistic impacts, while additional materials improve flexibility, impact resistance and overall efficiency.

![]()

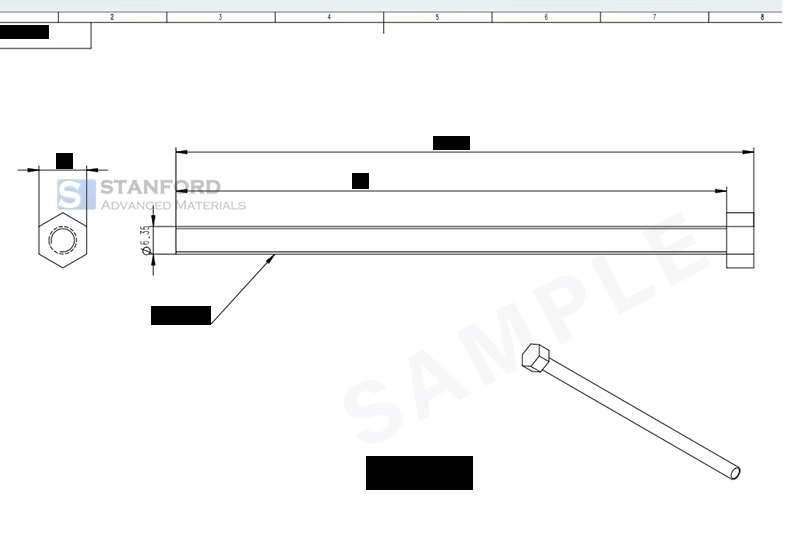

Figure 2. Silicon Carbide Plates

Applications of Silicon Carbide Plates in Defence

These materials are utilised in several sectors.

1. Ballistic Protection: Silicon Carbide plates are employed as inserts or panels in body armour systems. They reduce penetration by bullets, shrapnel and other ballistic threats. They are fitted in tactical vests, helmets and other gear used by military personnel, police officers and security forces.

2. Vehicle Armour: SiC plates are used to reinforce the armour of military vehicles, including tanks, armoured personnel carriers and other armoured vehicles. The high hardness and low weight of Silicon Carbide enable vehicle protection without substantially increasing the overall mass.

3. Aircraft Armour: In military aviation, these plates are incorporated as armour components in helicopters, aircraft and unmanned aerial vehicles (UAVs) to protect critical systems and crew against threats such as small arms fire and shrapnel.

4. Shields and Barricades: These plates are used to construct ballistic shields and barricades for law enforcement and security teams during high-risk situations such as hostage rescue operations or riot control.

Benefits of Silicon Carbide Plates for Defence

Silicon Carbide components provide several measurable advantages for the defence sector:

High Hardness: SiC ranks among the hardest known ceramics and offers resistance to projectile penetration and fragmentation.

Low Weight: SiC plates are relatively light compared with other armour materials; this quality improves mobility and wearability.

Protection against Various Threats: Silicon Carbide plates perform effectively against armour-piercing projectiles and high-velocity fragments.

Chemical Resistance: SiC resists a range of chemical substances and provides additional defence against specific chemical hazards.

Longevity: These plates deliver a prolonged service life, with resistance to wear, corrosion and degradation.

Conclusion

In summary, Silicon Carbide plates play an important role in modern protective equipment and armoured vehicles by offering high hardness, low weight and resistance to multiple threats. Their design is updated regularly to meet the evolving requirements of defence and security organisations.

Stanford Advanced Materials (SAM) is a reliable supplier of Silicon Carbide products. Custom modifications are available. Please contact us using the enquiry form if you are interested.

Reference:

[1] Mobile Defence. (2023, 02/08/2023). In Wikipedia. https://en.wikipedia.org/wiki/Mobile_Defence

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento