Positive Or Negative? A Beginner's Guide To Thermocouple Wire Identification

Thermocouples are essential instruments for temperature measurement and are utilised in various sectors such as manufacturing, food processing and aerospace. The principal function of a thermocouple is its ability to convert thermal energy into electrical energy, a process that depends on the junction of two different metals.

Although the concept appears straightforward, correctly identifying the thermocouple wires – distinguishing between the positive and negative conductors – remains crucial for precise temperature measurement. This beginner’s guide explains thermocouple wire identification so that you may confidently manage this essential aspect of thermocouple usage.

What are the Positive and Negative Conductors on the Thermocouple Wire?

The correct identification of thermocouple wires relies on an understanding of the colour coding system. Although this may vary by country and thermocouple type, a general rule applies: one wire is positive and the other is negative.

The identification of a thermocouple by its colour coding system is a necessary step for proper installation and troubleshooting in temperature measurement systems. Different thermocouple types employ varying metal combinations, and each type adheres to a specific colour code that assists users in accurate identification. The following guide outlines a straightforward method to identify thermocouples according to the wire colour coding, primarily based on the conventions established by the American National Standards Institute (ANSI) in the United States.

1. Familiarise Yourself with the Types of Thermocouples

Initially, it is important to become familiar with the various types of thermocouples. Each type is designated by a letter (e.g. K, J, T, E) and serves specific applications based on its temperature range and sensitivity. The most common types include:

Type K: Nickel-Chromium / Nickel-Alumel

Type T: Copper/Constantan

Type E: Nickel-Chromium/Constantan

2. How to Identify a Thermocouple via the Wire Colour Coding System?

In the United States, the ANSI standard is widely used. According to this standard, the wire colour corresponds to the thermocouple type.

The ANSI standard assigns specific colours to the insulation on thermocouple wires. This system aids in identifying both the thermocouple type and the positive and negative conductors. The following explanation details how some of the most common types are identified:

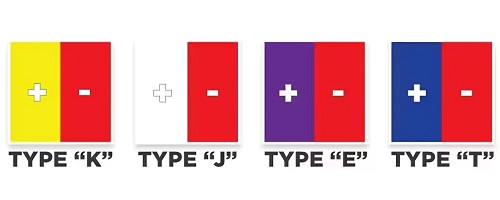

Type K: The positive wire is yellow, and the negative wire is red.

Type J: The positive wire is white, and the negative wire is red.

Type T: The positive wire is blue, and the negative wire is red.

Type E: The positive cable is violet, and the negative cable is red.

We focus on the ANSI and IEC colour codes for thermocouples, their wires and connectors, alloy combinations, maximum temperature ranges and specific codes. Below is the updated table:

|

ANSI-Code |

ANSI MC 96.1 Colour Coding |

Alloy Combination |

Max Temp. Range |

IEC 584-3 Colour Coding |

IEC-Code |

|

Type K |

Yellow (+) / Red (-) |

Ni-Cr / Ni-Al |

-270°C to 1372°C |

Green (+) / White (-) |

KX |

|

Type J |

White (+) / Red (-) |

Fe / Cu-Ni |

-210°C to 1200°C |

Black (+) / White (-) |

JX |

|

Type T |

Blue (+) / Red (-) |

Cu / Cu-Ni |

-270°C to 400°C |

Brown (+) / White (-) |

TX |

|

Type E |

Violet (+) / Red (-) |

Ni-Cr / Cu-Ni |

-270°C to 1000°C |

Violet (+) / White (-) |

EX |

|

Type N |

Orange (+) / Red (-) |

Ni-Cr-Si / Ni-Si |

-270°C to 1300°C |

Pink (+) / White (-) |

NX |

Key Components of the Table:

- ANSI-Code: Indicates the thermocouple type as per the American National Standards Institute.

- ANSI MC 96.1 Colour Coding: Displays the colour coding for thermocouple and extension wires according to ANSI standards. The colour for the positive conductor is listed first, followed by that of the negative conductor.

- Alloy Combination: Specifies the metals used in the positive (+) and negative (-) conductors for each thermocouple type.

- Max Temp. Range: Indicates the range within which the thermocouple can measure accurately.

- IEC 584-3 Colour Coding: Lists the colour coding for thermocouple wires according to the standards of the International Electrotechnical Commission, with the positive conductor’s colour described first.

- IEC-Code: The designation for the thermocouple type following IEC standards, with “X” indicating the extension grade.

This table provides detailed information on identifying thermocouples based on their ANSI and IEC colour codes and clarifies the differences between the American (ANSI) and International (IEC) coding systems.

3. Inspect the Entire Insulation Jacket

In addition to the colours of the individual wires, the overall insulation jacket of the thermocouple cable follows a colour code corresponding to the thermocouple type. This provides an immediate visual indication of the thermocouple type at hand:

Type K: Yellow jacket

Type J: Black or white jacket

Type T: Blue jacket

Type E: Violet jacket

4. Verify International Standards

Note that the colour coding system can differ by country. In Europe and other regions, the IEC colour coding system may be used, which differs from the ANSI standards. For instance, a Type K thermocouple according to IEC standards features a green positive wire and a white negative wire.

5. What to Do When the Colour Codes Are Not Visible?

If the colour codes are faded or not visible, use a multimeter to measure the resistance of the wires. Different metals exhibit distinct resistance values, from which the thermocouple type can be deduced. This method, however, requires an understanding of the resistance characteristics of the metals used in thermocouples.

6. Consult the Documentation

Whenever possible, consult the thermocouple documentation or the manufacturer’s guidelines. This approach provides the most reliable method to ensure correct identification, particularly for critical applications.

How to Identify a Thermocouple by Wire Colour in the Absence of a Visible Colour Code?

In cases where the colour code is not visible or has faded, alternative methods can be applied:

Resistance Measurement: Measuring the resistance between the thermocouple wires can, in some cases, assist in identification, since the metals involved usually have distinct resistance values.

Consulting the Manufacturer: In uncertain situations, contacting the manufacturer or referring to the thermocouple documentation will yield the most accurate information regarding wire identification.

Best Practices for the Use of Thermocouples

To ensure accurate temperature measurements, follow these practices:

Proper Installation: Ensure that the thermocouple is installed correctly, with the positive and negative wires connected to the appropriate terminals.

Routine Calibration: Thermocouples should be calibrated regularly to maintain measurement accuracy.

Avoid Mixing Types: Do not mix wires from different thermocouple types, as this can result in inaccurate readings.

Conclusion

Identifying thermocouple wires may seem challenging to novices. However, understanding the fundamental function of thermocouples, the available types and their associated colour coding clarifies the process. By following best practices and consulting reliable documentation or experts when necessary, you can ensure accurate and dependable temperature measurements in your applications. Note that correct identification of positive and negative values is essential for measurement precision.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento