Additive Manufacturing Vs Traditional Manufacturing

Introduction

Additive Manufacturing (AM) or 3D printing is a production method that alters traditional manufacturing processes in various sectors. Its ability to produce complex and custom-built objects by adding material layer by layer changes the way products are designed, prototyped and manufactured in industries such as aerospace, automotive, healthcare and consumer goods.

This article examines the features and benefits of AM by comparing it with conventional manufacturing methods. The analysis aims to aid in selecting appropriate AM materials for business or research applications.

What is Additive Manufacturing?

Additive manufacturing comprises a group of technologies that construct three-dimensional objects using a layer-by-layer process. In contrast to conventional methods that use subtractive techniques such as cutting, drilling and machining, additive manufacturing adds layers of material sequentially.

[1]

[1]

Figure 1. 3D printing

The typical steps in an AM process are as follows:

1. Design: The first step is to create a digital 3D model using CAD software. This model serves as a blueprint for the physical object.

2. Preparation: The digital model is sliced into thin cross-sectional layers. The slice thickness is determined and instructions for layer addition are generated.

3. Printing Process: The printing commences when the AM machine adds material layer by layer. For instance, in Fused Deposition Modeling (FDM) a thermoplastic filament is heated and extruded onto the build platform.

4. Post-processing: After printing, additional steps may be required to refine the object. These include removing support structures, cleaning, polishing and surface treatment to achieve the required properties.

Further Reading: 3D printing powders: what they are and how they are used?

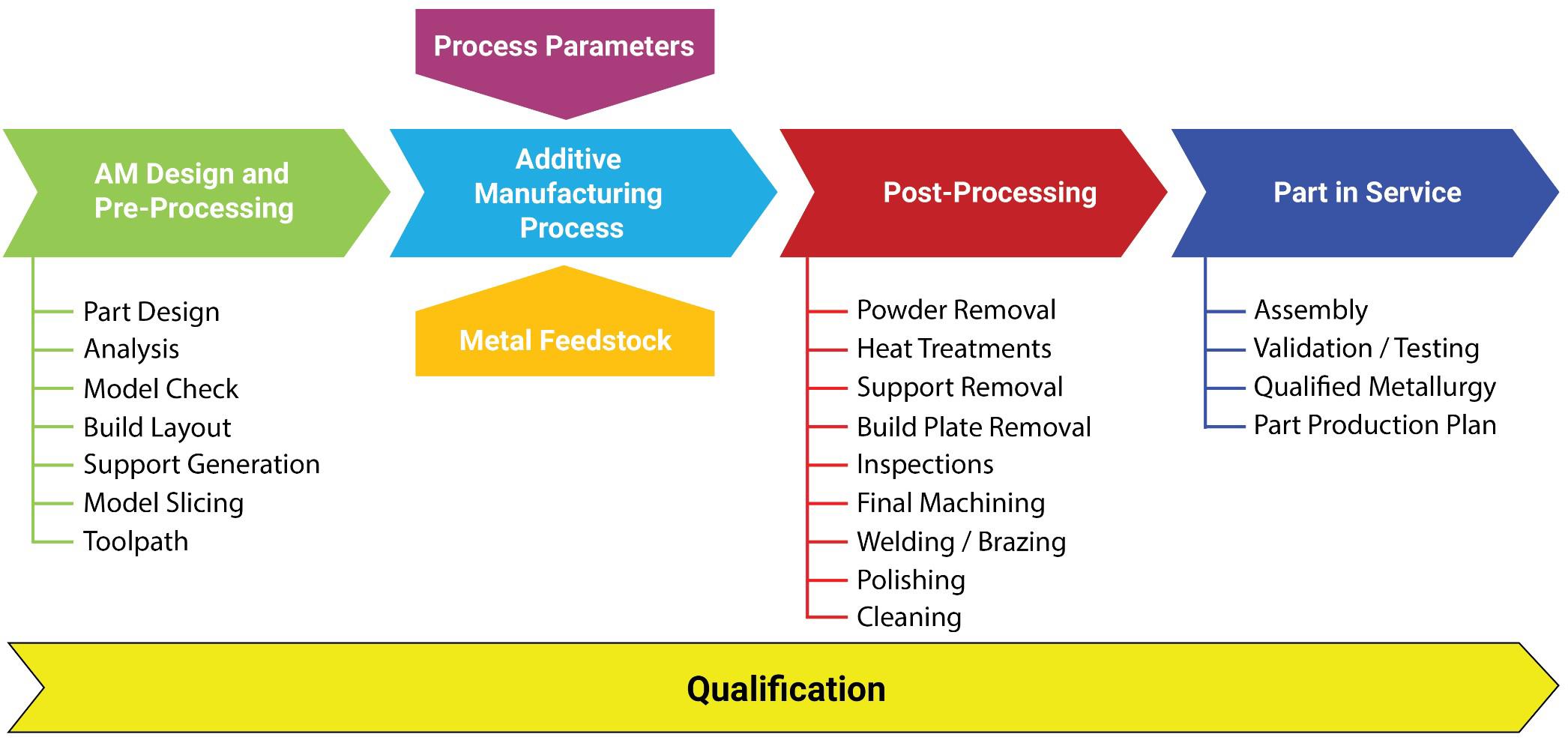

Figure 2. AM process

Additive Manufacturing Compared with Traditional Manufacturing

Recent technological developments have increased the use of additive manufacturing, which offers several measurable benefits over conventional methods.

- Complex geometries: AM allows the production of intricate patterns, including detailed internal structures and organic forms. Conventional methods impose restrictions.

- Customisation: The process facilitates adjustments to meet specific requirements without additional tooling costs or delays, whereas traditional methods are designed for mass production.

- Material efficiency: AM produces minimal waste by using only the required material. This results in reduced material costs and lower environmental impact.

- Equipment simplification: Conventional processes often involve several machines for distinct steps. In additive manufacturing, one machine manages the entire production process. In metal processing, traditional methods typically require turning, milling and drilling processes.

- On-demand production: AM supports decentralised, demand-driven production. This reduces the need for large inventories and permits local manufacturing. Companies may prototype and produce products with one machine instead of investing in extensive facilities.

Applications of Additive Manufacturing

Given these benefits, additive manufacturing is applicable in sectors such as aerospace, automotive, healthcare, consumer goods and architecture. The features outlined below illustrate differences when compared with conventional manufacturing.

Table 1. Additive Manufacturing Compared with Traditional Manufacturing

|

Additive Manufacturing |

Traditional Manufacturing |

|

|

Geometry |

No restrictions, detailed internal structures and organic forms |

Existing constraints |

|

Customisation |

Tailored to specific requirements |

Limited customisation |

|

Material efficiency |

Minimal material waste, reducing both costs and environmental impact |

Generation of by-products and material waste |

|

Setup requirements |

Desktop machines require a workshop environment with moderate space |

Industrial systems require significant space |

|

Purpose |

Mass customisation |

Mass production |

Conclusion

In summary, the comparison between additive manufacturing and traditional manufacturing demonstrates distinct differences. Additive manufacturing offers a method that produces complex geometries, enables customisation, supports rapid prototyping and improves material efficiency. Conventional methods remain fundamental for mass production.

The decision between AM and traditional manufacturing depends on factors such as production volume, design complexity, material requirements and time constraints. Consequently, understanding each method’s specifics is essential. For further information on AM materials, please visit Stanford Advanced Materials (SAM).

Reference:

[1] Thakur, Vishal & Singh, Roopkaran & Kumar, Ranvijay & Gehlot, Anita. (2022). 4D-Druck von thermoresponsiven Materialien: ein Überblick über den aktuellen Stand der Technik und künftige Anwendungen. International Journal for Interactive Design and Manufacturing (IJIDeM). 1–20. 10.1007/s12008-022-01018-5.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

.jpg)

Chin Trento

Chin Trento