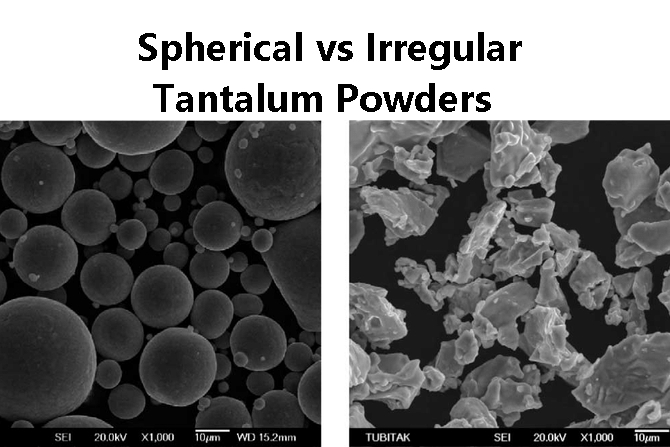

Spherical vs Irregular Tantalum Powders for Industrial Applications

Tantalum is a rare, corrosion-resistant metal with widespread usage in high-end industries such as electronics, aerospace, biomedical engineering, and additive manufacturing. While its inherent characteristics—such as high melting point (~3017°C), ductility, and chemical stability—are identical, the morphology of tantalum powders has considerable implications on processing efficiency, product performance, and material selection.

Let us discuss the technical and practical distinctions between spherical and irregular tantalum powders, and how they differ in their performance in significant industrial applications.

1. Morphology and Manufacturing

The primary distinction between spherical and irregular tantalum powders is their shape, which results from their manufacturing processes.

- Spherical tantalum powders are produced by advanced methods such as gas atomisation, plasma spheroidisation, and plasma rotating electrode processes (PREP). These methods either melt tantalum and spray it into fine droplets (which solidify as spheres) or reshape angular particles through surface tension in a plasma field.

- Tantalum powders with irregular shapes are typically generated through hydrogen-decrepitation (HDH), sodium or magnesium reduction of tantalum oxides, or mechanical grinding of sponge tantalum or scrap. These methods are less costly but give rise to rough, angular particles with a rough surface area.

2. Flowability and Packing Density

Flowability is of particular importance in operations such as additive manufacturing, cold pressing, and powder injection moulding. It is typically assessed using the Hall flow rate and angle of repose.

- Spherical powders exhibit better flow due to their smooth surface and minimal friction between particles. A typical spherical AM-grade tantalum powder (15–45 µm) will exhibit a Hall flow rate of 11–14 seconds per 50g and an angle of repose of 25°–30°.

- Irregular powders, by contrast, have poor flow with Hall flow rates typically >25 seconds per 50g and angles of repose >40° and are less suitable for processes where reproducible flow is required.

Similarly, tap density and bulk density are higher in spherical powders, typically up to 5.8–6.5 g/cm³ (tap density), compared to 4.0–5.2 g/cm³ for irregular shapes. This implies improved material utilisation and packing efficiency in sintering and additive processes.

Further reading: Gas-Atomised Spherical Powders: Addressing the Technological and Practical Challenges

3. Surface Area and Impurity Levels

Specific surface area, typically measured by BET analysis, influences sintering behaviour, chemical reactivity, and impurity pickup.

- Irregular powders have higher surface area—typically 0.5 to 1.2 m²/g—due to their rough morphology. This renders them more reactive, which is beneficial in applications such as capacitor anode production where surface area enhances performance.

- Spherical powders, with BET ranging from 0.10 to 0.30 m²/g, are less reactive to oxidation and contamination. They are ideal for applications where high purity and controlled sintering are required.

In terms of oxygen content, a very important impurity in tantalum, spherical powders have lower contents (~0.015–0.03 wt.%) even when produced in inert gas. Irregular powders may contain 0.05–0.15 wt.% oxygen or higher, depending on production and handling.

4. Application-Based Performance

4.1 Additive Manufacturing

Spherical tantalum powders are necessitated for Laser Powder Bed Fusion (LPBF) and Electron Beam Melting (EBM) due to their improved flow for uniform layer deposition, melt pool dynamics that can be predicted, and high packing density for dense parts.

- Studies show AM parts made from spherical powders exhibit >99.5% relative density, tensile strength of 550–650 MPa, and acceptable fatigue behaviour.

- Irregular powders, by contrast, are virtually unusable in AM due to their poor flow and non-uniform melting.

Further reading: Spherical Powder in Additive Manufacturing

4.2 Capacitor Manufacturing

Tantalum capacitors rely on powders with very high surface area to produce high capacitance per unit mass (CV/g). In this instance, fine, irregular powders are preferred.

- Irregular sub-10 µm powders, which are porous and tortuous, achieve 80,000–200,000 CV/g, depending on sintering and pressing.

- Spherical powders are not widely used due to low surface area and are generally not suitable for this purpose.

4.3 Biomedical Implants

Spherical powders are favoured in biomedical applications such as 3D-printed porous tantalum implants due to interconnectivity and controlled pore size, dimensional accuracy and uniform sintering, good biocompatibility and osteointegration.

- Implants produced by LPBF or binder jetting of spherical tantalum produce 60–80% porosity and pore diameters in the 300–500 µm range, which mimic cancellous bone architecture.

- Irregular powders can be used for traditional sintered porous materials but lack the precision and consistency of spherical feedstock.

4.4 Powder Metallurgy and Coatings

For general powder metallurgy (PM):

- Irregular powders offer fast sintering due to higher surface energy.

- Spherical powders provide more uniform shrinkage and higher mechanical strength, which is required for aerospace or high-stress uses.

In thermal and plasma spraying, the spherical powders are once more preferred for satisfactory feed behaviour and consistent coating thickness.

Summary Table: Spherical vs Irregular Tantalum Powders

|

Category |

Spherical Tantalum Powder |

Irregular Tantalum Powder |

|

Properties |

||

|

Shape |

Uniform spheres; |

Angular/rough; |

|

Production |

Produced via gas atomisation, plasma spheroidisation, or PREP |

Produced by reduction or mechanical crushing |

|

Flowability (Hall flow) |

Excellent (11–14 s/50g); Low angle of repose (25°–30°) |

Poor (>25 s/50g); High angle of repose (>40°) |

|

Tap Density |

High (5.8–6.5 g/cm³) |

Moderate (4.0–5.2 g/cm³) |

|

Surface Area (BET) |

Low (0.10–0.30 m²/g); Less reactive |

High (0.5–1.2 m²/g); More reactive |

|

Oxygen Content |

Low (~0.015–0.03 wt.%) |

Higher (~0.05–0.15 wt.%) |

|

Applications |

||

|

Additive Manufacturing |

Ideal for LPBF/EBM; high density, good mechanical strength |

Unsuitable due to poor flow and inconsistent melting |

|

Capacitor Production |

Generally unsuitable due to low surface area |

Preferred; achieves 80,000–200,000 CV/g |

|

Biomedical Applications |

Used in 3D-printed implants; controlled porosity, good biocompatibility |

Used in traditional sintering; less precise |

|

PM and Coatings |

Uniform shrinkage; consistent coatings; good for aerospace, medical, structural parts |

Faster sintering; used in general PM parts |

For more tantalum products, please check Stanford Advanced Materials (SAM).

Conclusion

The choice between spherical and irregular tantalum powders is based on a trade-off among technical performance, cost, and end-use requirements.

Spherical powders are optimal for applications such as additive manufacturing, biomedical implants, and aerospace parts, where flowability, purity, and mechanical properties are of prime importance. Irregular powders, conversely, find better use in capacitor manufacturing, chemical processing, and powder metallurgy components in general, where high surface area and reactivity are more important than flow or uniformity.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento