5 Reasons Aluminum Master Alloys Improve Casting Quality

Introduction

Casting is one of the oldest and most useful techniques in metal production. Quality castings are important in many industries such as automotive, aerospace, and construction. Aluminium master alloys play a key role in improving the casting process. These alloys are added to molten aluminium to change its properties. They help engineers achieve better products with fewer defects. I have seen many changes over my long career in the industry. Today, I wish to share five main reasons why aluminium master alloys improve casting quality.

Using aluminium master alloys is a practical method to get castings that are more reliable. The process is tried and true. Many plants rely on good alloy chemistry to produce high-quality castings. In this article, we cover five reasons. We explain each reason with simple examples and data. We discuss topics in plain language. This helps readers understand the benefits of aluminium master alloys, even if they are not experts.

Aluminium Master Alloys Improve Casting Quality

One key reason is enhanced fluidity. Molten metal must flow easily into every tiny crevice of a mould. When the metal flows better, it fills complex shapes without leaving gaps. For example, a casting mould with thin walls can often be filled completely with an alloy that has good fluidity. My experience shows that when aluminium master alloys are used, the metal flows with less resistance. The fluidity also affects the finishing of the casting. Better fluidity means fewer cold shuts and incomplete filling. This has been well documented in several plant tests. In many cases, fluidity improvements are measured in additional centimetres reached in flow length tests. Such improvements lead to fewer defects and a better final product.

Another important reason is the improvement of mechanical properties. Cast parts must be strong and resistant to forces. Aluminium master alloys help to form a structure that offers good strength and hardness. For instance, certain master alloys can increase tensile strength by up to 15% in some standard tests. A well-known example is the addition of a silicon-magnesium combination. In real cases, castings in the automobile industry have shown improved impact resistance and shock absorption. Engineers in plants typically refer to these improvements when high load-bearing parts are involved. The master alloys make the aluminium less brittle and increase its ductility. This means parts can bend without cracking, saving time and money in later stages of production.

A third reason is refined microstructure. A smooth, fine grain structure reduces many common casting defects. When the microstructure is refined, the casting shows better surface finishes and reduced porosity. There are several lab tests that show how grain size decreases with the introduction of aluminium master alloys. For example, a reduction of grain size by up to 20% has been measured in some trials. A refined microstructure results in fewer shrinkage cavities and fewer micropores in the outer layer of the casting. Such improvements help in applications that require precision parts. Many industries, including the electronics sector, rely on fine details and smooth surfaces. I recall cases when a slight refinement in the microstructure led to a significant boost in performance. The result is castings that maintain uniform properties from one section to another.

The fourth reason is better control of alloying elements. Master alloys offer precision in adding needed elements to the base aluminium. This allows foundries to keep the composition within tight limits. In control experiments, plants have recorded a composition control within plus or minus 0.2%. This level of control is very important for critical components. It leaves little room for error in the final performance of the casting. For common examples, a mix that includes silicon for fluidity and magnesium for strength will be properly balanced. In many cases, using a master alloy avoids the risk of adding extra elements by mistake. It also helps to avoid a mismatch in the expected performance of parts. Consistent alloy chemistry results in more uniform castings. Regular checks in foundries show that improved control has reduced defect rates by nearly 10%.

The fifth reason is economic benefits. It is always wise to consider the cost of production. Aluminium master alloys can lead to cost savings during the casting process. An alloy that flows well or has a refined microstructure lowers the incidence of scrap parts. Less scrap means lower production costs. Many foundries run cost comparisons and find that the extra cost of adding master alloys is offset by the savings in labour and material re-use. For example, a plant may reduce rework expenses by 5% to 10% after using these alloys. In my years of working with foundries, I have seen that better castings lead to longer-lasting parts. This, in turn, means fewer returns and warranty claims from customers. Over time, these savings add up and every company benefits.

The advantages mentioned before have a lasting impact on quality. When competition in the market is tough, quality becomes a key differentiator. Many foundries have relied on aluminium master alloys to provide a competitive edge. Lower scrap rates, better mechanical properties, and high-quality finishes are all part of the reason why these alloys matter. I have often advised young engineers to consider not only the present process but also long-term reliable performance. Master alloys support sustainable practices and better end results.

In practice, the benefits are evident in everyday production lines. Many actual casting facilities have adopted the use of aluminium master alloys over the years. They report fewer rejects and smoother production cycles. Investment in these alloys is seen as a valuable upgrade to a sound production process. The measured increase in performance also speaks for itself. The typical weight of scrap reduction and profit increases has been presented in detailed case studies. Such data reinforces the important role of master alloys across different sectors of aluminium casting.

Before we move to the conclusion, let us sum up the five reasons: enhanced fluidity, improved mechanical properties, refined microstructure, better control of alloying elements, and economic benefits. Each reason plays a part in ensuring that cast parts are strong, reliable, and produced at a good value. End users notice the differences in tool quality and safety. In industries where even small defects can lead to large repairs, consistency counts a great deal.

Conclusion

Aluminium master alloys improve casting quality in several tangible ways. Their use results in castings with better flow, better strength, smoother grain structure and controlled composition. They offer benefits in production cost and overall efficiency.

Frequently Asked Questions

F: How do aluminium master alloys affect metal flow in

casting?

Q: They improve molten metal flow into complex moulds, reducing gaps and cold

shuts.

F: What common improvements in strength are seen with these

alloys?

Q: Castings show up to a 15% increase in tensile strength and enhanced

ductility.

F: Can master alloys help lower production costs?

Q: Yes, by reducing scrap rates and production rework, they lower overall

costs.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

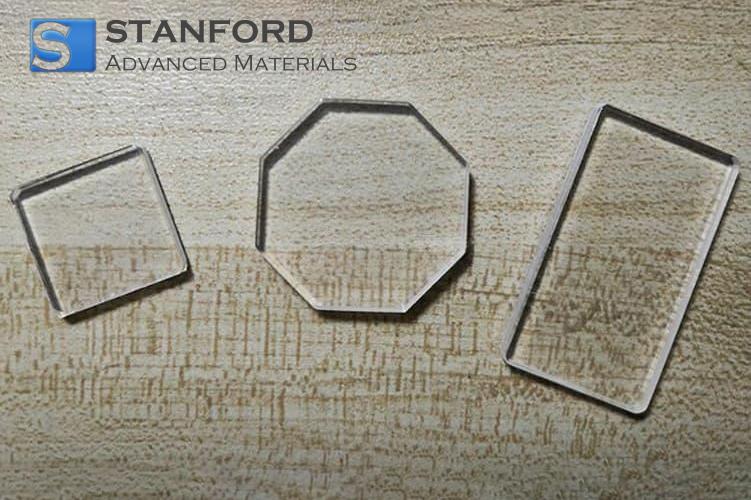

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

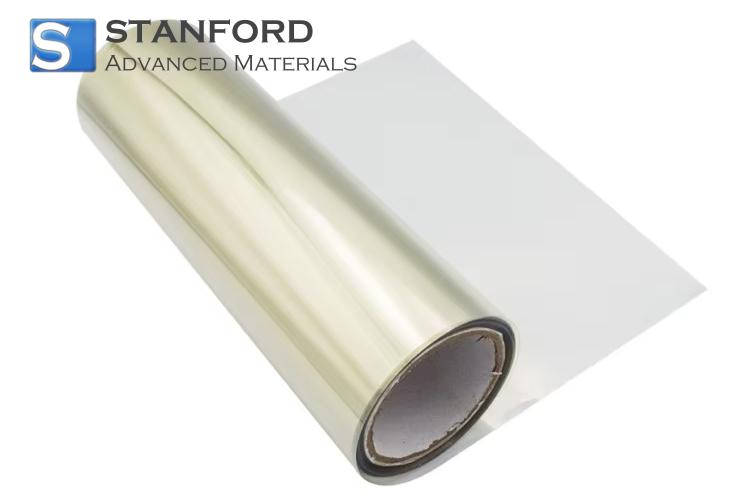

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento