Bismuth: Element Properties And Uses

Description

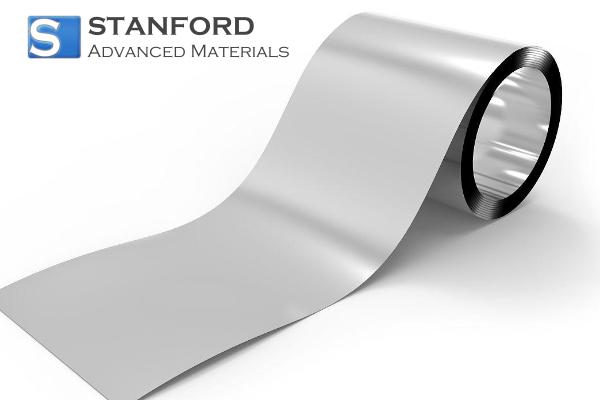

Bismuth is a brittle metal, silvery-white in colour, but often with a pinkish tint. This non-toxic, diamagnetic metal is friendly to the environment and finds applications from pharmaceuticals to electronics.

Introduction to the Element

Bismuth is an interesting element that possesses an atomic number of 83. One of the heaviest stable elements, bismuth differs in its properties in several aspects. It is non-toxic, unlike many of the heavy metals, which makes it more attractive and a very good option over more injurious materials such as lead. The crystal structure of bismuth is rhombohedral, which enhances its appearance and makes it look brilliant. Due to its unique combination of physical and chemical properties, bismuth has found applications in industries over time.

Chemically, bismuth resembles antimony and arsenic, members of its group, but its low toxicity and peculiar crystalline properties make this metal especially useful in applications related to safety and sustainability.

Chemical Properties Description

Bismuth typically occurs in an oxidation state of +3 in its compounds, but under suitable conditions, a +5 state can be achieved. With a high density and low thermal conductivity, surprisingly, bismuth is a very poor electrical conductor. Due to this aspect, its applications are limited to areas such as non-toxic solders or low-melting alloys. Another advantage for everyday uses, from pharmaceuticals to industrial processes, includes the fact that under normal conditions, bismuth does not oxidise, leading to good stability and long-term reliability.

Physical Properties

Bismuth has a number of physical properties that distinguish it from many other metals. It has a density of 9.78 g/cm³, making it heavier than lead; however, it is brittle instead of malleable like lead. The melting point for bismuth is relatively low at 271.5°C while its boiling point is considerably higher at around 1,564°C. It also exudes a unique crystalline structure that gives way to visually striking and colourful patterns during cooling, contributing to its aesthetic appeal in a variety of cosmetic applications.

Key Physical Properties:

- Atomic Number: 83

- Atomic Weight: 208.98 g/mol

- Density: 9.78 g/cm³

- Melting Point: 271.5°C

- Boiling Point: 1,564°C

- Crystal Structure: Rhombohedral

Applications

The versatility and low toxicity of bismuth make it suitable for manifold applications across several industries—from healthcare to electronics. Following are the major areas where bismuth finds its use:

1. Medicinal Applications:

Bismuth is best known in the pharmaceutical business for its application as a digestive aid. A medication composed of bismuth, known as bismuth subsalicylate, has been used in products such as Pepto-Bismol and Kaopectate. These over-the-counter products are used to treat nausea, heartburn, and diarrhoea. Bismuth exerts an astringent effect on tissues and helps protect the mucous lining of the stomach from irritants, thereby efficiently healing gastrointestinal disturbances. It also possesses mild antimicrobial properties that help in the treatment of Helicobacter pylori infections, which are responsible for peptic ulcers.

2. Lead Replacement:

Historically, lead has been used in a variety of applications but, due to its toxicity, industries have sought safer alternatives. Bismuth is used as a nontoxic alternative element to lead in alloys, solders, plumbing, and fishing weights. In these uses, the low toxicity and relatively similar properties of bismuth to lead (for example, low melting points) make it an ideal substitute. This use is particularly important in the electronics industry, where lead-free solders are becoming the norm due to environmental concerns and regulations such as RoHS.

3. Cosmetics:

Bismuth oxychloride is used extensively in the cosmetic industry for preparing products with a pearly sheen, like lipsticks, eyeshadow, and nail polish, due to its natural iridescence, which confers a smooth, shiny finish. Bismuth, being of low toxicity, is an attractive alternative to materials that may cause irritation. This is of great importance in products intended for sensitive skin.

4. Electronics:

Bismuth is being used in various ways in electronic devices, mainly in the preparation of thin films and conductive materials. Bismuth telluride is an example of one such compound that finds its application in thermoelectric devices because of its high thermoelectric efficiency. Researchers are still exploring bismuth's potential in semiconductor technologies and the capability to enhance electrical properties when it is used in thin layers. The non-toxic character of bismuth makes it a potential candidate for use in more sustainable electronic components, furthering the push toward eco-friendly electronics.

5. Industrial Applications:

Bismuth also finds broad applications in industry, particularly in metallurgy and as a metallurgical additive. It is used in various alloys aimed at modifying their properties, like bismuth low-melting-point alloys used in fire-detection devices. Such alloys have been extremely useful in applications where safety and low toxicity are required. Besides this, its unique physical properties make it useful in the manufacture of high-quality mirrors and other industrial parts.

Preparation Methods

Bismuth is normally produced as a by-product in refining of other metals like lead, copper, tin, and tungsten. Extraction involves the hydrometallurgical method, where bismuth is separated from the other metals by chemical reaction and precipitation. The extracted bismuth is purified to meet high standards for industrial and pharmaceutical applications. Advanced electrorefining and precipitation methods ensure purity in bismuth and its compounds.

Frequently Asked Questions

What is unique about bismuth among all heavy metals?

Bismuth is known for its low toxicity, its striking crystalline structure, and its non-toxic alternatives to other heavy metals, such as lead.

How is bismuth usually extracted from its ores?

Most of the bismuth produced today comes as a by-product from the refining of other metals, especially lead, copper, and tin, by advanced hydrometallurgical and purification techniques.

In what common products is bismuth used?

The main uses of bismuth include pharmaceuticals, cosmetics, fire detection devices, low-melting alloys, and a replacement for lead in specific industrial applications.

What are the major chemical properties of bismuth?

Bismuth has stable oxidation states, low reactivity, and forms complex compounds; therefore, it serves a number of chemical uses.

Why is bismuth an environmentally friendly alternative in industrial applications?

Bismuth is considered non-toxic and stable; hence, it is a safer alternative for hazardous materials such as lead. It reduces the environmental and health risks of lead and other hazardous materials.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento