Catalyst: Properties, Types, And Uses

Catalysts and Catalysis

A catalyst is a substance that increases the rate of a chemical reaction without undergoing permanent change. Catalysis refers to the mechanism by which catalysts lower the activation energy required for a reaction. This property makes catalysts indispensable in industrial, biological and environmental applications. They enable reactions to occur under milder conditions and improve process efficiency, thereby reducing energy consumption and waste production.

Properties of Catalysts

Catalysts possess specific characteristics that make them essential for diverse applications:

lActivity – Catalysts increase reaction rates by providing an alternative reaction pathway that requires lower activation energy. They remain unconsumed during the reaction.

lSelectivity – Catalysts can favour particular reactions over others. This ensures that the target product is produced with minimal by-products.

lStability – Catalysts must withstand reaction conditions such as high temperatures, elevated pressure or chemical exposure without decomposing.

lRegenerability – Many catalysts can be regenerated and reused. This attribute supports cost-effective and sustainable operations.

lSurface – Materials with a high surface area are preferred since a greater number of active sites enhances catalytic efficiency.

Common Types of Catalysts

Catalysts can be classified into different types based on their form and function:

lHomogeneous Catalysts – These catalysts exist in the same phase (liquid or gas) as the reactants. They provide uniform mixing and high reactivity. However, separation after the reaction may be required. For example, sulphuric acid is used in esterification reactions.

lHeterogeneous Catalysts – These catalysts occur in a different phase to the reactants, such as solid catalysts in liquid or gaseous reactions. They are easier to separate and reuse. For instance, iron is employed in the Haber process for ammonia synthesis.

lEnzymes (Biocatalysts) – Enzymes are natural catalysts found in living organisms. They promote biochemical reactions with high specificity and efficiency.

lPhotocatalysts – These catalysts are activated by light and are used in processes such as water splitting and air purification. For example, titanium dioxide (TiO2) is utilised in solar energy applications.

lElectrocatalysts – These catalysts facilitate electrochemical reactions. They are applied in systems such as fuel cells and batteries. Platinum is used in hydrogen fuel cells.

Precious Metal Catalysts

Precious metal catalysts, including platinum, palladium, rhodium and ruthenium, are valued for their excellent catalytic properties. They are used in industries that require precise and reliable performance.

lPlatinum (Pt) is commonly utilised in automotive catalysts to reduce harmful emissions and in fuel cells to generate clean energy.

lPalladium (Pd) is effective in hydrogenation and dehydrogenation reactions and finds use in pharmaceutical and petrochemical industries.

lRhodium (Rh) is applied due to its resistance to poisons and high temperatures in crude oil refining and in vehicle exhaust systems.

lRuthenium (Ru) is employed in ammonia synthesis, organic conversion reactions and water treatment systems.

These metals are often supported on carrier materials. The carriers enhance performance by dispersing the active sites and providing thermal and chemical stability.

Frequently Asked Questions

How do catalysts lower the activation energy?

Catalysts provide an alternative reaction pathway that requires less energy. Consequently, more molecules reach the required activation threshold.

Can a catalyst be reused?

Yes, most catalysts can be regenerated and reused. This depends on their stability and resistance to fouling.

What is the difference between a homogeneous and a heterogeneous catalyst?

Homogeneous catalysts exist in the same phase as the reactants. Heterogeneous catalysts occur in a different phase, which simplifies separation procedures.

Why are precious metals used in catalysts?

Precious metals exhibit high activity, selectivity and stability. Consequently, they are suited for demanding industrial processes.

Are catalysts environmentally friendly?

Yes, catalysts improve efficiency, reduce energy consumption and minimise waste, thereby contributing to processes with a lower environmental impact.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

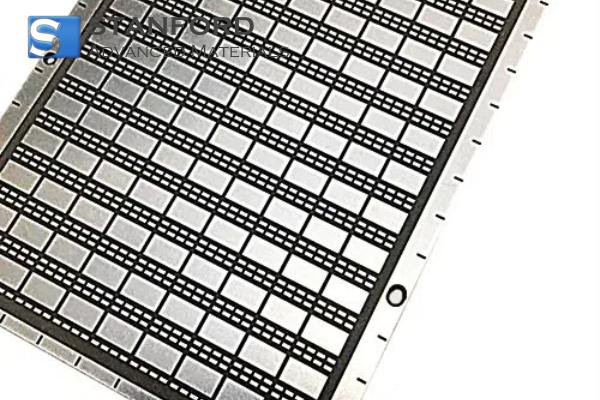

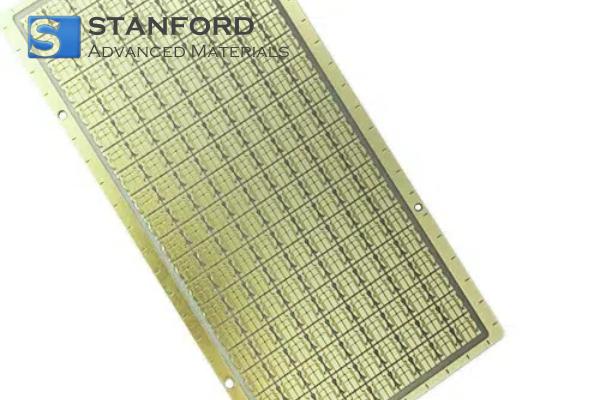

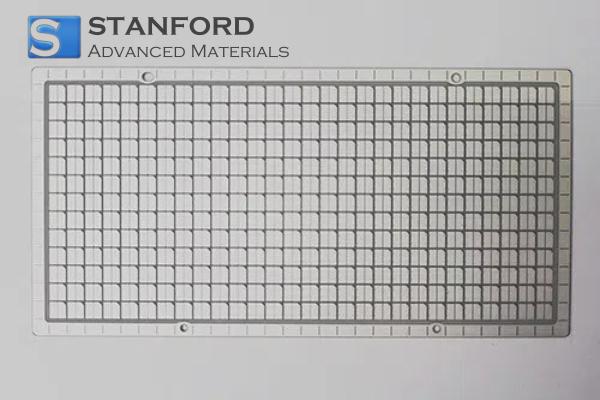

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento