Chromium: Element Properties And Uses

Description

Chromium belongs to the class of transition metals, which are predominantly known for their hardness, resistance to corrosion, and lustrous metallic features. It finds significant application in most industries, ranging from stainless steel production to its use in protective coatings and the manufacture of specialised chemicals. Chromium is resistant to tarnishing due to the formation of its protective oxide layers; hence, it is an indispensable material in aerospace, automotive, and manufacturing.

Chromium the Element

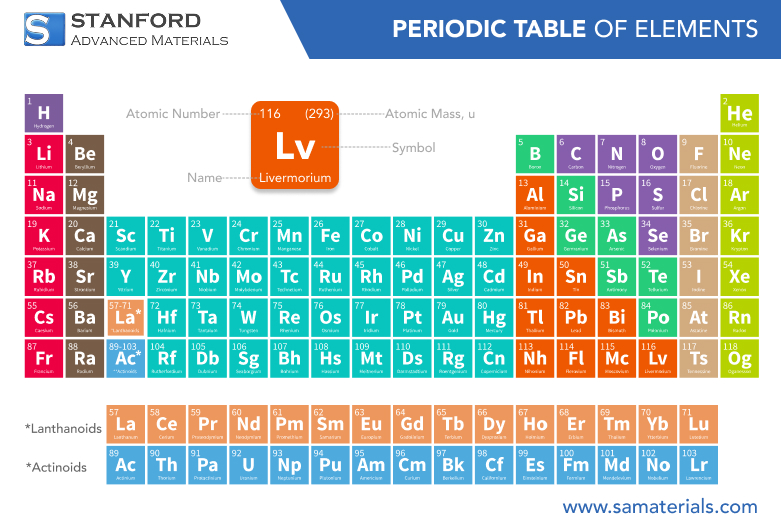

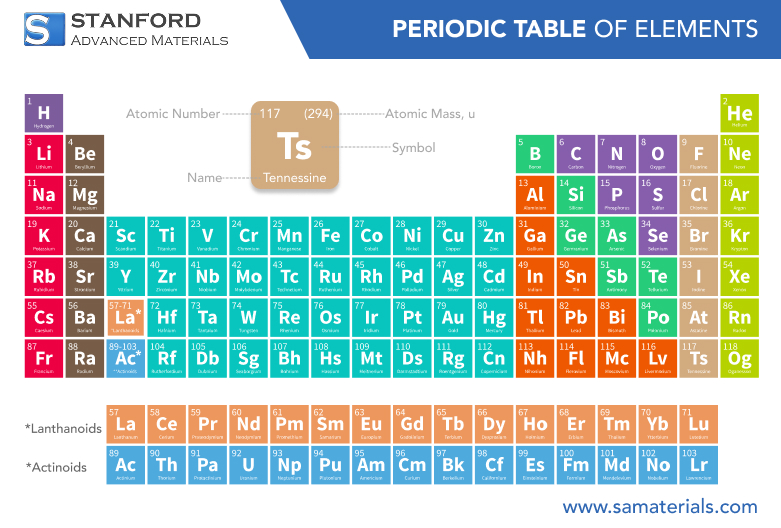

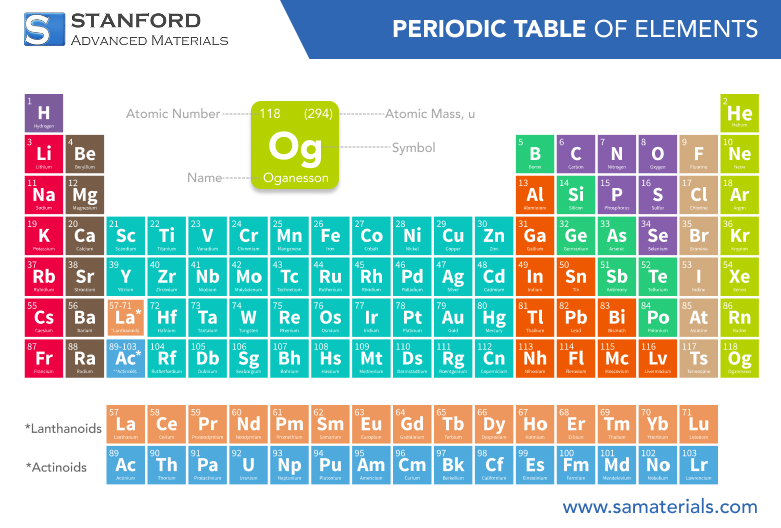

Chromium, with the atomic number 24, belongs to the transition metals and falls under Group 6 of the periodic table. Chromium was discovered in 1797 by a French chemist named Louis-Nicolas Vauquelin. It usually occurs in nature as part of the mineral chromite, FeCr₂O₄. The element is highly valued for its hardness, resistance to corrosion, and its striking metallic lustre. Chromium is most notably used to create materials that are both durable and resistant to environmental wear, making it essential to a variety of industrial processes.

Chemical Properties Description

Chromium is a versatile element with vast differences in its chemical properties; its value lies in a wide range of its industrial applications:

- Oxidation States: The oxidation states of Chromium range from -2 to +6. Among them, the most stable and common are +2, +3, and +6. Chromium in the +3 state is usually stable, while the +6 state, or chromium hexavalent, is highly toxic and carcinogenic.

- Reactivity: Chromium readily combines with oxygen in the air to form a thin, protective oxide layer Cr₂O₃, which helps to prevent further oxidation. This oxide layer is crucial to chromium's resistance to corrosion. It can also combine with sulphur and halogens to give various compounds like chromium sulphide and chromium halides.

- Acid and Base Behaviour: Cr₂O₃ is amphoteric; that is, it can react with both acids and bases. This property enables chromium compounds to participate in a wide range of chemical reactions, hence their usefulness in catalysis or otherwise in industrial processes.

- Toxicity: While +3-valent chromium is an essential element in trace quantities for human health, its +6 oxidation state is toxic and carcinogenic, especially in industrial applications. Cr⁶⁺ exposure can occur via inhalation, ingestion, or skin contact and entails serious health risks.

Physical Properties Data Table

It is a heavy, hard, silvery metal with a very high melting and boiling point, which makes it ideal for use in industry at high temperatures. Some of the key physical properties are tabulated below:

|

Property |

Value |

|

Atomic Number |

24 |

|

Atomic Mass |

52.00 g/mol |

|

Density |

7.19 g/cm³ |

|

Melting Point |

1907°C |

|

Boiling Point |

2671°C |

|

Electrical Resistivity |

2.3 x 10⁻⁶ Ω·m |

|

Thermal Conductivity |

93 W/m·K |

|

Colour |

Silvery metallic |

More information can be found at Stanford Advanced Materials.

Common Uses of Chromium

That special combination of physical and chemical properties makes chromium indispensable in various industries. The most prominent uses of chromium include the following:

- Stainless Steel Production: Chromium is a very important alloying element in the production of stainless steel, enabling unparalleled resistance to corrosion and staining. The Chromium content usually ranges from 10% to 30% in stainless steel, and it forms a passive oxide layer that protects the steel from rusting and tarnishing. These steels have found a wide application area in products ranging from kitchenware and medical instruments to construction and aerospace.

- Chrome Plating: Chromium is used very commonly in electroplating to give a bright, durable, and corrosion-resistant finish. Chrome plating is normally applied to automotive parts, household appliances, plumbing fixtures, and decorative items. This enhances both the aesthetic appeal and the durability of these products.

- Pigments and Dyes: Chromium compounds, including chromium oxide (Cr₂O₃), are used as pigments for paints, dyes, and inks. Chromium yellow, PbCrO₄, is the well-known pigment used in the manufacture of bright yellow paints. The more stable chromium oxide is used to create the green pigments in ceramic glazes and plastics.

- Alloys: Chromium finds its application in a number of high-performance alloys for industrial, aerospace, and military applications. For instance, chromium is alloyed with nickel and iron to create superalloys utilised in turbine blades, engines, and exhaust systems. These alloys exhibit a high degree of resistance against heat and wear, which makes them suitable for harsh conditions.

- Wood Preservation: Chromium compounds, most notably treatment with chromated copper arsenate, are used to treat wood to make it resistant to decay, fungi, and insect attack. Because of this resistance, CCA-treated wood finds much application in outdoor structures, such as fencing and decking, as well as in utility poles.

Preparation Methods

The major method for the extraction of chromium is the aluminothermic reaction; the ore generally used is chromite, FeCr₂O₄. In this process, the chromite is mixed with aluminium powder and heated, thereby causing the reduction of chromium oxide to produce metallic chromium. Chromium can also be produced through the electrolysis of chromium chloride in molten salt; this process is used for high-purity applications. While these methods are energy-intensive, they provide a highly reliable supply of chromium for industrial use.

Related Industrial Products

Chromium is used in the manufacture of many industrial products:

- Stainless Steel: Chromium, usually in combination with nickel and molybdenum, is the basis for stainless steel, which is applied in everything from food processing to construction and medicine.

- Chromium Alloys: Chromium alloys are used in applications that demand high strength, resistance to heat, and toughness. Examples can be seen in components like turbine blades, engine parts, and heavy machinery components.

- Chromium Chemicals: The manufacture of chemicals is another important field in which chromium is a key raw material. This includes chromium salts, chromium dioxide, used in magnetic recording media, among other specialised compounds. These are applied in several fields that range from tanning leather to water treatment and the processes of electroplating.

Frequently Asked Questions

What is chromium used for in everyday life?

Uses of chromium mainly include the production of stainless steel for kitchen appliances, cutlery, medical instruments, and industrial machinery. It is also used in chrome plating for automotive parts, household items, and decorative finishes.

How is chromium extracted?

The extraction of chromium from chromite ore involves the aluminothermic reaction of the ore with aluminium powder, which is heated to reduce chromium oxide to metallic chromium. On top of this, various electrolytic methods have been developed to yield even purer chromium.

Why is chromium dangerous?

Chromium is toxic and carcinogenic, especially in its hexavalent form (Cr⁶⁺). It presents health hazards upon inhalation or ingestion. Industrial exposure to this element is very common and thus proper precautions should be implemented while handling chromium compounds in an industrial context.

Does chromium play an essential role in human health?

Yes, trivalent chromium (Cr³⁺) is an essential trace element that plays a role in the regulation of glucose metabolism. However, it is needed in only small amounts and deficiency is rare.

What is the major source of chromium?

Most chromium is derived from chromite ore, mainly found in the countries of South Africa, India, Kazakhstan, and Turkey. These countries are the major chromite ore producers in the world.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

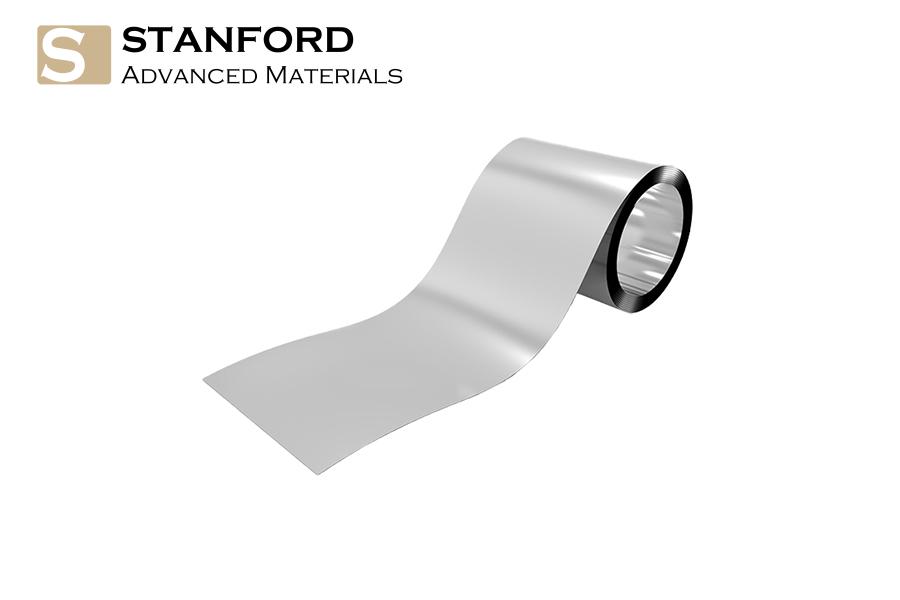

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento