How To Choose Grinding Beads For Wet Milling

Understanding Your Milling Objectives

Before choosing Milling Beads, you must specify your milling objectives. Firstly, define a clear target particle size. For instance, if extremely fine particles are required, beads capable of reducing the particle size to that specification must be used. Next, consider the hardness of your material: harder materials require beads with high abrasion resistance, whereas softer materials allow for more flexibility. Finally, assess the sensitivity of your application. Certain products, such as biomedical suspensions, require a minimal contamination risk and controlled milling conditions.

Selection of Bead Material Based on Chemical Compatibility and Abrasion Resistance

Choosing the correct bead material is essential. The selected material should not react with your product and must withstand extensive mechanical stress.

- Zirkoniumdioxid: Zirkoniumdioxid beads exhibit high hardness and demonstrate strong abrasion resistance. They are appropriate for milling abrasive or high-density materials. In ceramic processing, it has been observed that zirconium dioxide spheres maintain their dimensions after prolonged use.

- Glas: Glass beads minimise the risk of metal contamination. They are appropriate for processing soft or sensitive substances. Numerous coatings and pigments have been milled using glass beads.

- Stahl: Steel beads possess high density and strength. They are suitable for milling hard, high-density materials. However, they may introduce metal particulates into the product if the material is highly sensitive.

- Tonerde und Siliziumnitrid: Beads made from clay and silicon nitride exhibit high chemical resistance and maintain durability over extended periods. These are used in applications that require high purity and minimal contamination. In some instances, alumina beads have also been successfully employed in pharmaceutical manufacturing.

Each option has specific characteristics. The decision must be made based on your material properties and process requirements.

Consider the Bead Size and Distribution

The size and distribution of your milling beads significantly affect the milling process.

- Smaller beads: They provide a larger effective impact area. They are preferable when achieving a fine particle size distribution is necessary. Their increased collision frequency contributes to effective comminution.

- Larger beads: They are more suitable for milling materials with larger particles or when higher impact forces are required. They can manage increased milling loads without premature degradation.

- Mixed sizes: In certain circumstances, using a combination of small and large beads can yield a balanced milling effect. Such a mixture may promote a more uniform particle size distribution. In some industrial applications, this approach has reduced processing time by measurable margins.

Maintaining a good distribution is sometimes more effective than using a single bead size exclusively.

Evaluate the Bead Density and Its Effects on Milling

Bead density is another factor that influences the milling outcome.

- Higher density beads: They deliver increased impact energy. They are recommended when milling hard materials. In cases where the material is compact, high density beads contribute to a finer milling result.

- Lower density beads: They produce a gentler impact. They are suitable for processes involving sensitive materials. These beads reduce the likelihood of over-milling and may decrease heat development.

Selecting the appropriate density helps to control the collision intensity and is important for optimising energy transfer in your milling machine.

Assessment of the Contamination Risk

Contamination is a critical consideration. Some bead materials may shed particles or react chemically with the substance being milled. When milling food, pharmaceuticals or high-technology materials, the risk must be kept to a minimum. If contamination is a significant concern, glass or ceramic beads are generally the more appropriate choice compared to steel beads.

Consider Costs and Lifecycle

Each type of bead has its acquisition cost and projected service life. Some options are more expensive but endure for a longer duration. It is advisable to balance initial costs with long-term performance. In industrial environments, even modest savings on bead costs can accumulate over time.

Consider the maintenance and replacement expenses. Beads that wear rapidly may lead to increased downtime and higher overall costs. Therefore, lower initial costs do not always result in long-term benefits.

Testing and Optimisation

Once your selection has been narrowed, conducting a small-scale trial is beneficial. Begin with a test run using a batch of beads. Assess the particle size, consistency and the occurrence of any unwanted by-products. Then adjust the milling parameters accordingly.

Tests allow you to determine whether the selected beads deliver the required performance. They also provide the opportunity to verify if further parameter adjustments are necessary. The process may require several modifications before the optimal settings are achieved.

Conclusion

Selecting the appropriate milling beads for wet milling is an important step. Maintain a focus on your milling objectives. Choose bead materials that meet both the chemical and mechanical requirements of your process. Decide on the appropriate bead size, distribution and density. Weigh the contamination risk along with the costs and lifespan. Finally, test your selection and adjust parameters as required to achieve consistent results. With a clear plan and systematic testing, you can attain consistent milling performance and product quality.

Frequently Asked Questions

Q: What factors are important when selecting beads?

Q: The key factors include milling objectives, material compatibility, bead size and density.

Q: Can I mix beads of different sizes?

Q: Yes. A mixture can provide a balanced milling effect and a more even particle size distribution.

Q: How can I assess the performance of the beads?

Q: Conduct a small-scale trial and compare the consistency of the particle size as well as the amount of wear over time.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

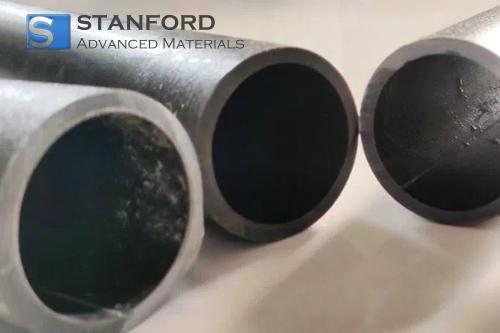

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento