Indium: Element Properties And Uses

Description

Indium is a rare metal, soft, with specific chemical and physical properties. Its crucial role in electronic, semiconductor, and industrial applications has made it an important material for modern technologies.

Indium the Element

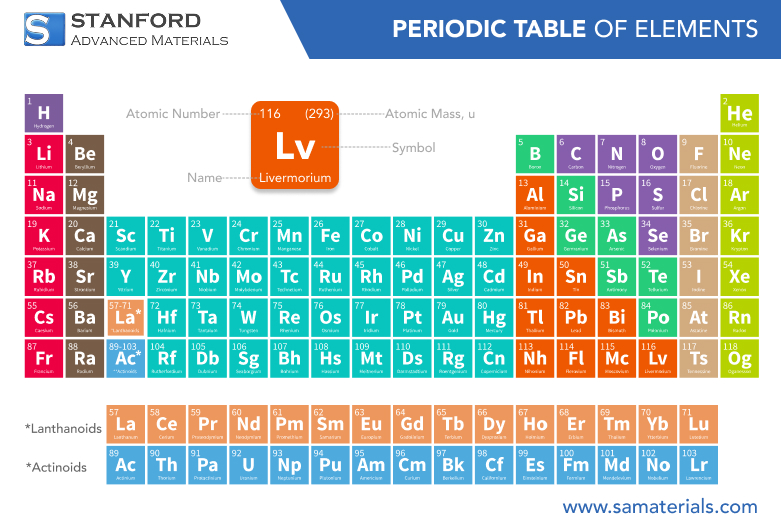

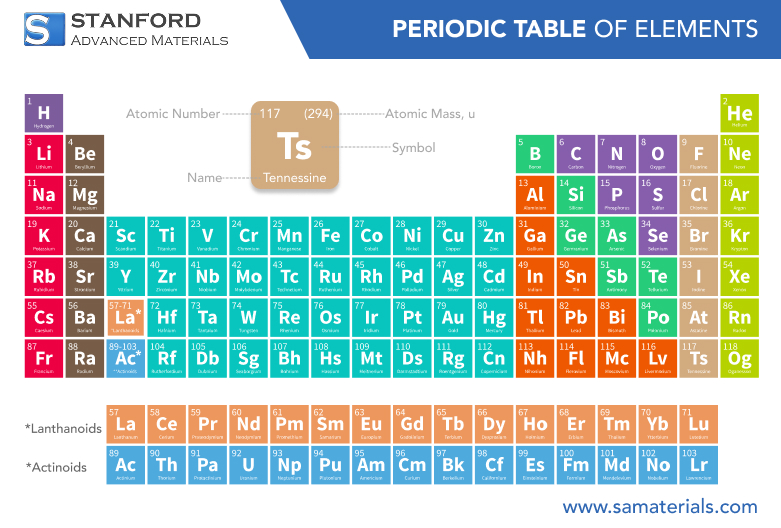

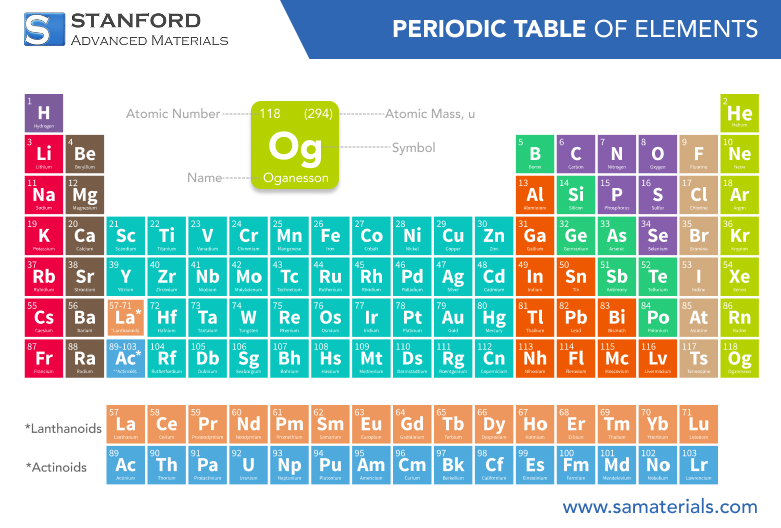

Indium is a post-transition metal with the symbol In and atomic number 49. It holds a unique place in the periodic table. Discovered in 1863 by Ferdinand Reich and Hieronymous Theodor Richter, indium is a relatively rare element in the Earth's crust. It is mostly extracted during the processing of zinc ores; most of the world supply comes from this method.

Chemical Properties Description

Indium has a common oxidation state of +3 and forms indium oxide, In₂O₃, and indium chloride, InCl₃, which are critical in semiconductor and catalytic applications. Sometimes indium can also have an oxidation state of +1, giving the element versatility in chemical reactions and compound formation.

Indium is somewhat inert at room temperature because of the thin, protective oxide layer that forms over its surface and protects it from further oxidation. This passivation layer increases the stability of the metal under normal conditions, which provides a greater range of possible industrial uses. In more reactive or acid-rich environments, indium readily dissolves and generates salts which then can go on to be used in various chemical processes.

Physical Properties

|

Property |

Value |

Unit |

|

Atomic Number |

49 |

- |

|

Atomic Weight |

114.82 |

g/mol |

|

Density |

7.31 |

g/cm³ |

|

Melting Point |

156.6 |

°C |

|

Boiling Point |

2072 |

°C |

|

Electrical Conductivity |

1.34e6 |

S/m |

|

Crystal Structure |

Tetragonal |

- |

For more information, please check Stanford Advanced Materials (SAM).

Thermal and Electrical Properties

Electrical conductivity by indium is very good, hence fitting for use in electronics. It has a relatively low melting point at 156.6°C and is suitable for applications that require low melting alloys—for instance, in safety fuses. Indium also has very high thermal conductivity, which ensures heat is dissipated efficiently in different applications, especially semiconductor devices and heat-sensitive machinery or equipment.

Methods of Preparation

Owing to its rarity, most of the commercial production of indium is obtained as a by-product of zinc mining. Extraction is usually performed through hydrometallurgical procedures, leaching indium with acid solutions from the ore. Processes involving pyrometallurgy are also known, particularly concerning electronic scrap and recycling of industrial waste. Of course, a combination of all these methods provides high-purity indium in industrial amounts.

Common Uses

Indium possesses a unique combination of properties that make it indispensable in a wide range of high-tech applications:

1. Indium Tin Oxide (ITO) for Displays

The main application of indium today is in the synthesis of indium tin oxide, ITO, used in LCDs, flat panel displays, and touchscreens. ITO has excellent electrical conductivity associated with optical transparency, making it highly suitable for use in modern electronic devices.

2. Low-Melting Point Alloys

Low-melting-point alloys include indium, which can be used in safety devices like thermal fuses and fire-detecting systems. Such alloys are specially designed to melt at predetermined temperatures for dependable protection against hazards.

3. Electronics Soldering

Indium is widely applied in soldering applications of electronics, which helps in making reliable electrical connections that guarantee the durability of the device. The low melting point and its good wetting properties make it essential for its usage in high-performance solder joints.

4. Semiconductor Devices

Indium is used in semiconductor device manufacturing, including diodes, transistors, and integrated circuits, because the material can form stable compounds that are ideal for precise, reliable components in electronic systems.

5. Special Coatings

Indium is also used in a number of specialty coatings that enhance heat and corrosion resistance. These fall under the categories of aerospace and electronic manufacturing where performance under extreme conditions is required.

Frequently Asked Questions

1. What is indium, and why is it important?

Indium is a rare metal adopted for several applications in high-tech industries, such as electronics, semiconductor manufacturing, and safety devices. Its distinctive features make this material indispensable in industries related to electronics and display technology.

2. How is indium extracted?

Indium is mainly obtained during the processing of zinc ores as a by-product. The extraction encompasses hydrometallurgical routes, such as acid leaching, along with pyrometallurgical recycling of electronic wastes.

3. What are the major uses of indium?

Indium finds applications in the manufacture of ITO for displays, low-melting-point alloys for safety devices, soldering in electronics, semiconductor devices, and special coatings in the aerospace and electronic industries.

4. Why is indium used in soldering?

Indium has been used in soldering because of its low melting point, excellent wetting properties, and its ability to form strong, reliable electrical connections. These properties are essential for high-performance electronics.

5. What are the chemical properties of indium?

Indium usually adopts the +3 oxidation state and forms stable compounds, such as indium oxide and indium chloride, which are widely used in various semiconductor and catalytic processes. This also makes it inert at normal temperatures due to a protective oxide layer.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento