Lead: Element Properties And Uses

Description

Lead, or Pb, is a dense, soft, bluish-grey metal well-acknowledged for its resistance to corrosion, its malleability, and its blocking of radiation. These attributes make the metal valuable in industries that range from energy storage to medical imaging. At the same time, lead is widely recognised for its toxicity, shaping modern regulations and driving a move towards safer handling practices across the globe.

Introduction to the Element

Lead is one of the most historic metals ever used, with an atomic number of 82. For centuries, its ease of shaping and relative abundance made it indispensable in building materials, pipes, paint pigments, ammunition, and even household goods. Ancient civilisations like Rome employed lead widely, ignorant of the long-term dangers associated with such prolonged exposure.

Today, the risks of lead toxicity are well understood, thanks to scientific advances. That understanding has transformed how societies use and regulate the element. Its presence in consumer goods has greatly declined, yet lead continues to play a vital role in modern technologies requiring its density, stability, and predictable chemistry. Applications ranging from automotive manufacturing to nuclear energy continue to make use of it, but under conditions closely controlled by the rigours of modern health and safety standards.

Chemical Properties Description

Chemically, it exhibits typical properties for a post-transition metal, normally existing in its +2 oxidation state, but reaching +4 under strongly oxidising conditions. When exposed to air, it forms a gradual coating of lead(II) oxide, which helps to protect the metal from further corrosion. This oxide layer can react further to form a variety of salts, many of which have found specialised uses in industrial chemistry and in materials science.

Lead's moderate reactivity allows it to be stable under most normal conditions. It does not dissolve easily in cold water, nor is it quick to oxidise like many other metals. These chemical properties are of greatest significance for the uses of lead in protective coatings, the manufacture of certain kinds of glass, and in the positive plates of lead-acid batteries. Current studies of lead compounds further extend the frontiers for energy-related applications, catalysis, and radiation shielding.

Physical Properties

Lead exhibits a rare combination of heaviness, softness, and low melting point among all other metals. It has an atomic weight of 207.2 g/mol and a density of 11.34 g/cm³, considerably heavier than iron or copper. It melts at 327.5 °C and boils at 1749 °C; these temperatures allow it to be shaped and processed without excessive energy input. These characteristics have long made it an attractive material for casting, forming, and shielding applications.

For more information, please check Stanford Advanced Materials (SAM).

Common Applications

Despite being less intrusive in domestic objects, lead still maintains its strong relevance in contemporary industry. Among the most significant ones now is the production of lead-acid batteries. These supply power to automobiles, backup systems, forklifts, and renewable-energy storage systems. The redox chemistry involving lead and lead dioxide provides such efficiency, reliability, and low cost to the system that it remains dominant even while other battery technologies are expanding.

Lead also remains a material of choice for radiation shielding. Its density and atomic structure allow it to absorb harmful X-rays and gamma rays, making it indispensable in hospitals, dental clinics, nuclear facilities, and research laboratories. From protective aprons to shielding walls, lead ensures safe operation in environments where radiation exposure must be strictly controlled.

In addition, the metal is used in construction materials, specialised solders, vibration-damping components, and certain types of glass and ceramics. Although its use in paint, petrol additives, and plumbing has been phased out, lead still serves many industrial roles where alternatives are either less effective or more expensive.

Preparation Methods and Industrial Production

Lead is mostly extracted from the mineral galena, which is a lead sulfide ore. The extraction begins by roasting the ore in order to change the sulfide into oxide. Then, the oxide is reduced with carbon to produce metallic lead. Following this initial smelting phase, refining steps include electrorefining or additional smelting to remove impurities and produce high-purity lead suitable for battery grids, radiation shields, and precision alloys.

These production processes are continuously refined to enhance efficiency and lower the amount of environmental emissions. Modern facilities often operate under strict controls to limit lead dust, airborne particulates, and wastewater contamination.

Environmental Impact

The environmental impact of lead is very high because it is persistent and toxic. It does not degrade once released into the environment but accumulates in soil, water, and biological tissues. In addition, long-term exposure risks have been generated worldwide through sites of contaminated industries, old buildings with lead paint, and corroded lead pipes.

In natural systems, lead can enter waterways through runoff or improper waste disposal, where it poses a danger to aquatic life and can eventually enter the food chain. Human exposure—even at low levels—poses serious health risks, especially to children, in whom it may affect neurological development. These environmental concerns are one of the major reasons why, today, industries follow strict emissions rules, and many countries have established remediation programmes for legacy contamination.

Recycling and Sustainability

One of the most positive aspects of lead use today is how efficient its recycling system is. Lead is among the most recycled metals in the world, mainly by the battery industry, which exceeds 95 percent in many regions. Recycled lead is chemically identical to newly mined lead, enabling it to be reused over and over again without loss of quality in a closed-loop system that dramatically reduces the need for new mining and minimises environmental hazards associated with disposal.

Recyclable materials require vastly less energy than virgin extraction, which is both economically and environmentally more viable. For instance, most automotive batteries are collected, disassembled, and processed in well-regulated plants where lead, plastic, and acid are all recovered and put to new use.

Regulatory Standards

Because of its toxicity, the use of lead is subject to strict regulatory frameworks worldwide. Agencies in the United States, such as the U.S. Environmental Protection Agency, the Occupational Safety and Health Administration, and the European Chemicals Agency in Europe, establish limits on workplace exposure, environmental discharge, and allowable levels in consumer products. Regulations like the U.S. Lead and Copper Rule or Europe's RoHS directive make sure that in water systems, electronics, and manufacturing processes, lead is handled carefully.

These standards are designed to protect workers and consumers while making sure that industries using lead act responsibly, with minimal environmental impact and proper waste management.

Frequently Asked Questions

What is the atomic number of lead?

The atomic number of lead is 82.

How is lead extracted from its ore?

It is mainly extracted from galena through roasting and reduction smelting.

What are today's major uses of lead?

The most important applications include lead-acid batteries, radiation shielding, construction materials, and specialised electronics.

What chemical properties characterise lead?

Lead generally has a +2 oxidation state, forms stable oxides, and reacts moderately with air and moisture.

Why is lead so heavily regulated?

As lead is toxic and accumulates in the environment, its use is carefully controlled to protect public health and ecosystems.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

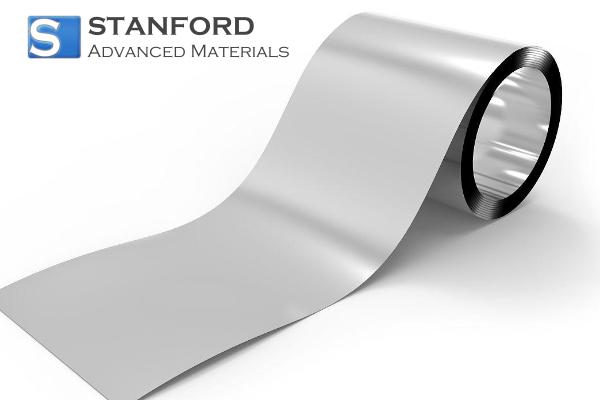

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento