The Essential Guide To Metallurgy And Materials

Description

Discover a detailed guide to metallurgy and materials science that explains the behaviour of metals, various processing techniques and daily applications. Learn in plain language how these materials influence modern technology and everyday life.

Introduction

Metallurgy and materials science are disciplines that affect nearly every aspect of daily operations. When holding a mobile phone, driving a vehicle or drinking from a metal mug, the contributions of metallurgists and materials scientists are evident. This publication examines fundamental principles, established procedures and practical applications of metals and materials in both standard items and advanced industry.

Metallurgy is the study of metals. In simple terms, it investigates how metals behave, how they can be modified and how they can be formed into useful objects. Materials science addresses various types of materials – including ceramics, polymers and composites. These disciplines are used to understand how materials can be altered, to increase durability and to enhance efficiency, thereby meeting specific engineering standards.

Learning about Metals and their Properties

Metals are distinct in that they share properties such as hardness, electrical conductivity and malleability. Their capacity to conduct electricity and heat is a primary reason for their widespread use in applications ranging from wiring to cookware. Their ability to be reshaped under controlled conditions makes them suitable for manufacturing.

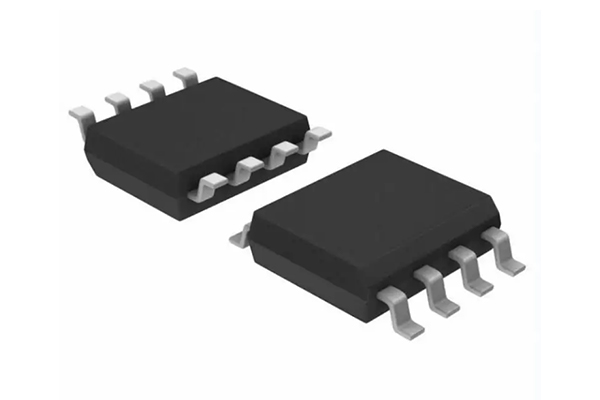

Different metals possess measured properties. Iron is used frequently in construction due to its strength. Aluminium is lighter than iron and offers excellent corrosion resistance. Copper is noted for its high electrical conductivity and is therefore commonly employed in electronic applications. Engineers rely on this factual property data when selecting the appropriate metal for specific functions.

Metallurgical Techniques and Procedures

Metallurgists employ various procedures to convert raw metals into finished products. One of the oldest methods is melting, in which metal ores are heated until the metal separates from impurities. Refinement procedures are then applied to reduce impurities so that the metals can meet the standards required in aerospace and automotive engineering.

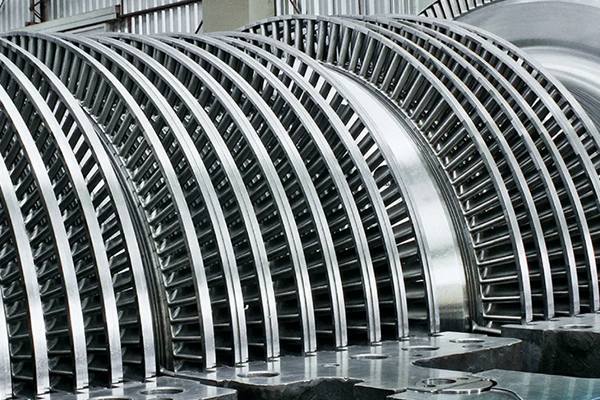

Other procedures include forging and alloying. During forging, metals are deformed under heat and pressure to modify their internal structure. During alloying, two or more metals are combined to produce a material with increased strength or improved wear resistance.

These procedures are used not only in the manufacturing of everyday items but also in the production of machine components and devices used in renewable energy systems, thereby supporting technological development.

Applications in Industry and Daily Life

Metallurgy and materials science form the basis of many modern industries. For instance, the automotive sector utilises metal alloys that combine low weight with sufficient strength to produce fuel-efficient vehicles without compromising safety. In electronics, compact metal circuits and connectors ensure device functionality.

In the field of medicine, materials science plays a significant role. Hip prostheses and dental braces are manufactured using specialised metals that are both durable and biocompatible. In these applications, materials must be long-lasting and safe for human use.

Advances in metallurgy have resulted in the development of responsive materials whose properties change when exposed to different external conditions such as temperature or load. Recent studies indicate that certain processing methods reduce processing times by 15%. Further information is available at Stanford Advanced Materials (SAM).

Frequently Asked Questions

Q: What is metallurgy?

A: Metallurgy involves acquiring knowledge about metals by studying their properties, refining them and forming them into useful products using methods such as melting, alloying and forging.

Q: How can the study of metals influence current technology?

A: The study of metals contributes to technological progress by enabling the production of materials that are more durable, lighter and longer-lasting; these materials are used in vehicles, mobile phones, medical devices and other applications.

Q: What procedures are used to ensure environmental safety in metallurgy?

A: Environmental safety is achieved through metal recycling, the application of energy-efficient processes and the reduction of gas emissions during processing, thereby providing an environmentally acceptable route for material development.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento