Everything You Should Know About Metals And Alloys

Description

Metals and alloys are utilised across multiple sectors. They are employed in construction, transportation, electronics, and medicine. Their strength, thermal and electrical conductivity, and durability make them essential components of modern infrastructure. This article examines the properties and uses of metals and alloys.

-What are Metals?

Metals possess high electrical and thermal conductivity. They are malleable and ductile and exhibit a shiny appearance. They occur naturally in ore. They are extracted via mining and refined through processing.

Metals are generally classified into ferrous metals (e.g. iron, such as steel) and non-ferrous metals (e.g. copper, aluminium, and titanium).

-What are Alloys

An alloy is a mixture of two or more metals. It may also consist of a metal combined with non-metallic elements. These components are combined to enhance strength, durability, corrosion resistance, or other characteristics. Alloys are produced by melting and mixing the base metal with additional elements.

-Properties of Metals and Alloys

- Physical - High density, a high melting point, and both thermal and electrical conductivity.

- Mechanical - Strength, hardness, ductility, formability, and toughness.

- Chemical - Corrosion resistance, reactivity, and oxidation resistance.

- Magnetic - Some metals are ferromagnetic (Fe, Ni, Co); others are not magnetic.

- Machinability - Formability, weldability, and overall machinability vary according to the specific metal or alloy.

-Applications of Metals and Alloys

Metals and alloys are employed in numerous fields. In construction, steel and aluminium support the build of buildings, bridges, and roads. In automotive manufacturing, aluminium alloys reduce the weight of engine parts, wheels, and body components. In medicine, titanium alloys are used for bone implants and surgical instruments due to their strength and biocompatibility.

Types of Metals and Alloys

-Precious Metals

Precious metals are recognised for their durability, rarity, and aesthetic quality. These metals include gold, silver, and platinum, which have been used historically for coins, jewellery, and as stores of value. They also exhibit corrosion resistance and conductivity. Consequently, they are used in various industrial applications.

Gold is one of the best-known precious metals. It is utilised in electronics, dentistry, and as an investment asset.

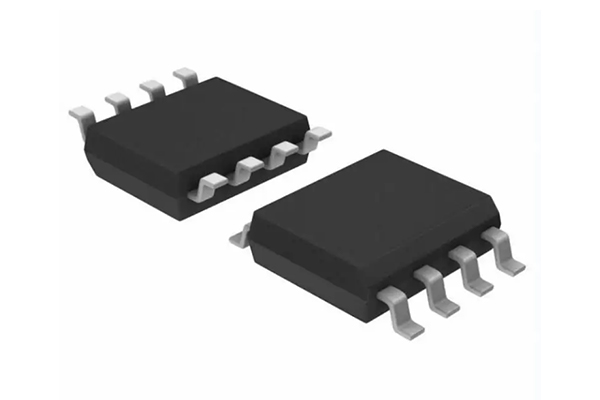

Although silver is frequently used for jewellery and coins, it is notably valuable for electrical components, solar cells, and medical applications.

Platinum is rarer and more expensive. It is used in automotive catalytic converters, chemical processing, and laboratory equipment.

-Refractory Metals

Refractory metals are recognised for their high melting points, hardness, and resistance to heat and wear. They include tungsten, molybdenum, tantalum, and niobium. These metals are capable of withstanding extreme temperatures and harsh conditions, for instance in aerospace, nuclear reactors, and high-performance engines.

Tungsten has a melting point exceeding 3 400 °C. It is used in incandescent bulbs and aerospace applications.

Molybdenum is commonly used in steel alloys.

Tantalum is employed in electronics and medical implants due to its excellent corrosion resistance.

Niobium is often used for superconducting materials.

--Superalloys

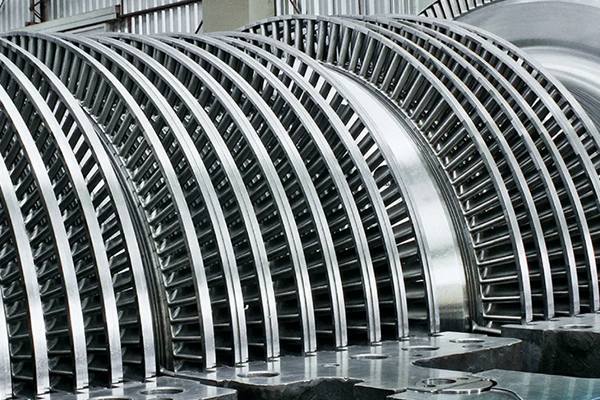

Superalloys are suitable for severe conditions, including very high temperatures, high pressures, and aggressive chemical environments. These alloys consist of a primary metal such as nickel, cobalt, or iron. They are often combined with elements including chromium, aluminium, and titanium to enhance their properties.

Nickel-based superalloys hold particular importance in the aerospace industry. They are used in turbine blades, engine components, and jet engines.

Cobalt-based superalloys are frequently utilised in gas turbines and chemical processing plants.

Iron-based superalloys are found in power generation facilities.

Frequently Asked Questions

1. Why are alloys stronger than pure metals?

The intermixture of atoms hinders the sliding of layers. This reduces the likelihood of bending or breaking.

2. Can alloys rust?

Some alloys can rust, for example pure carbon steel. However, many, such as stainless steel or bronze, are formulated to resist rust and corrosion.

3. Are all metals magnetic?

No. Only a few, such as iron, nickel, and cobalt are naturally magnetic. Most others, such as aluminium or copper, are not.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento