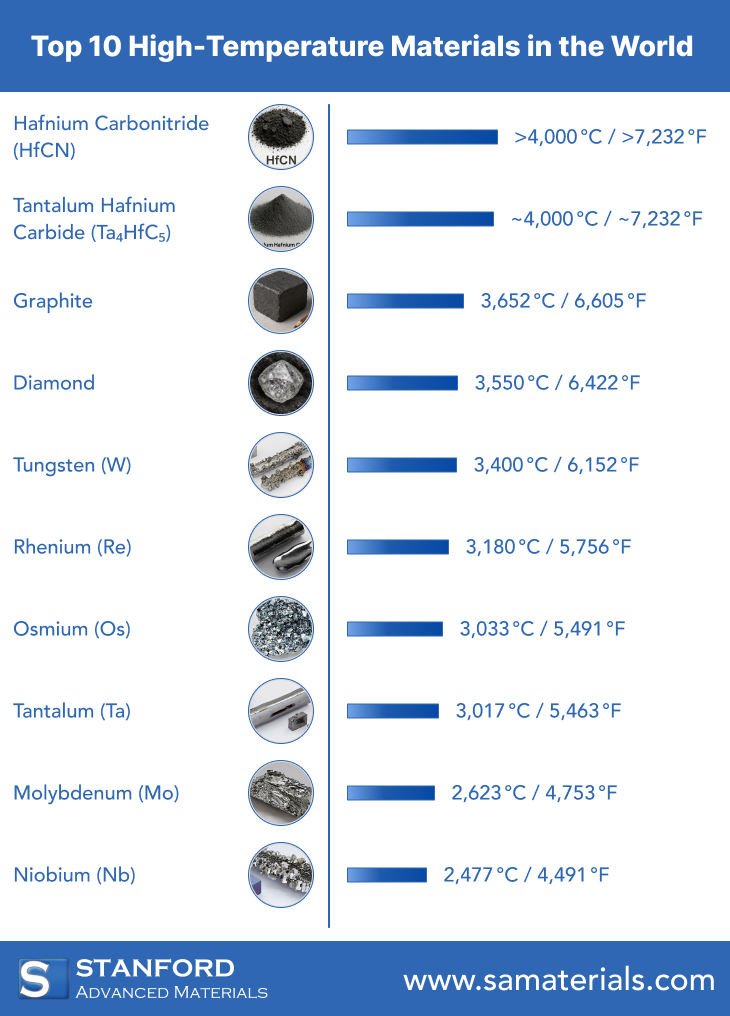

Top 10 High-Temperature Materials in the World

1. Hafnium Carbonitride (HfCN) – >4,000 °C / >7,232 °F

Hafnium Carbonitride can resist temperatures greater than 4000°C (over 7232°F). Its ability to sustain such temperatures makes it very useful in extreme environments. For example, it is sometimes used in aerospace parts and high-performance engines. This material demonstrates excellent hardness and stability. Its chemical stability makes it ideal for high-temperature coatings and advanced ceramics. Engineers work with this material when they require a substance that remains reliable under intense heat.

2. Tantalum Hafnium Carbide (Ta₄HfC₅) – ~4,000 °C / ~7,232 °F

Tantalum Hafnium Carbide withstands temperatures around 4000°C (approximately 7232°F). This material is known for its rare ability to function effectively in the most extreme conditions. In practice, components made from Tantalum Hafnium Carbide are useful in advanced aerospace designs and foundry work. Its performance and size stability distinguish it from many other materials. It is chosen by experts when reliability at high service temperatures is mandatory.

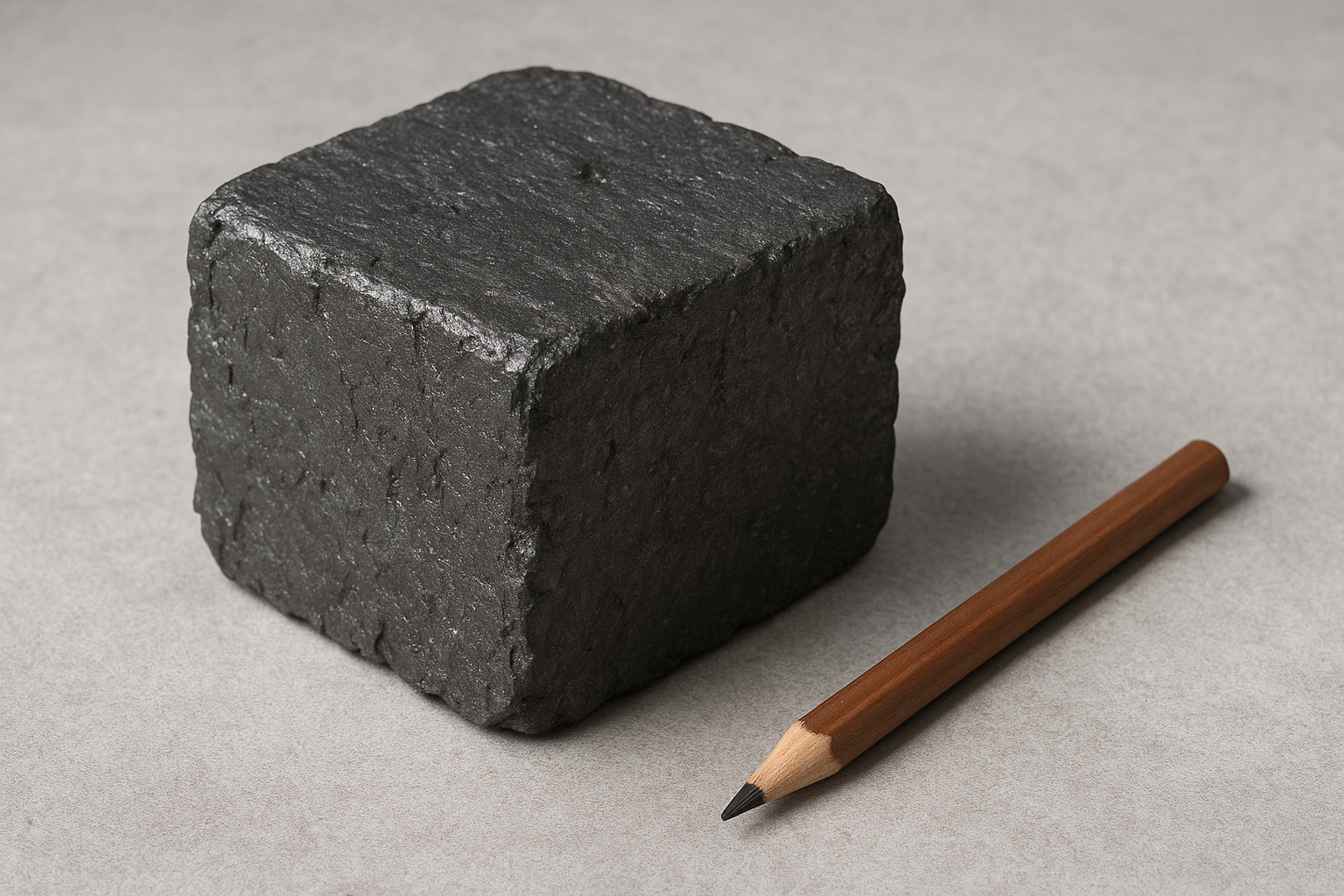

3. Graphite – 3,652 °C / 6,605 °F

Graphite can handle temperatures up to 3652°C (6605°F). This form of carbon is widely known for its use in high-temperature furnaces and as a lubricant in industrial processes. Graphite is also common in the manufacturing of electrodes for electric arc furnaces. Its layered structure explains why it not only endures heat but also provides excellent thermal and electrical conductivity. Simple graphite parts can be found in everyday industrial applications where heat resistance is vital.

4. Diamond – 3,550 °C / 6,422 °F

Diamond, with a stable limit of around 3550°C (6422°F), is notable for its exceptional hardness and high thermal conductivity. Although diamonds are prized as gemstones, their industrial use surpasses their decorative appeal. Industrial diamonds are used in cutting tools and polishing compounds. Their natural lattice structure allows them to conduct heat away from critical areas, which is why they are sometimes applied in heat sinks for electronics and cutting instruments. Simple forms of diamond are regularly utilised in high-performance machining.

5. Tungsten (W) – 3,400 °C / 6,152 °F

Tungsten has an impressive threshold of about 3400°C (6152°F). Renowned for its very high melting point and density, tungsten is a preferred material in the manufacture of filaments for incandescent lighting and in the aerospace industry for high-heat components. Its ability to remain stable under prolonged heating makes it indispensable in industrial furnaces. Additionally, tungsten is used in electrical contacts and heavy-metal alloys that require exceptional resistance against thermal deformation.

6. Rhenium (Re) – 3,180 °C / 5,756 °F

Rhenium endures temperatures up to roughly 3180°C (5756°F). Although rare and expensive, its role in superalloys used in turbine engines is important. Rhenium adds strength and heat resistance to these alloys. Parts in jet engines and industrial turbines often include a small amount of rhenium to strengthen the overall material. The simplicity of rhenium's structure and its high-temperature resilience are valued in specific applications.

7. Osmium (Os) – 3,033 °C / 5,491 °F

Osmium withstands temperatures around 3033°C (5491°F). It is one of the densest elements and is typically used in alloys where extreme durability is required. Although osmium has limited practical use on its own, its inclusion in specialised alloys benefits high-temperature applications in scientific instruments and precision machinery. Its natural resistance to deformation under heat makes it a useful additive in composite materials used in industry.

8. Tantalum (Ta) – 3,017 °C / 5,463 °F

Tantalum can endure temperatures up to about 3017°C (5463°F). It is known for its corrosion resistance and reliability even under stress. Due to this strength, tantalum is used in chemical processing equipment and heat exchangers. Its excellent conductivity and ability to withstand aggressive environments make it a consistent choice in both industrial and high-tech contexts. Simple parts from tantalum are included in circuits and medical implants requiring resistance to high temperatures.

9. Molybdenum (Mo) – 2,623 °C / 4,753 °F

Molybdenum reaches temperatures up to 2623°C (4753°F). This metal is known for its good strength retention at high temperatures and is used in furnace parts and high-speed steel. Molybdenum can be found in everyday applications where the material must maintain performance under high heat. Its use in steel alloys serves to improve strength and durability, making molybdenum a common additive in automotive and energy conversion industries.

10. Niobium (Nb) – 2,477 °C / 4,491 °F Tantalum

Niobium has a high-temperature limit of around 2477°C (4491°F). It is often utilised to enhance the overall performance of superalloys. Niobium is combined with other metals for turbine blades in jet engines and parts in industrial applications. Its contribution to stability and strength under severe temperature conditions is well appreciated. Simple niobium components assist in extending the life of high-temperature machinery.

Further reading: Melting Point: Common Materials, Metals, and Elements

Conclusion

High-temperature materials are crucial to modern engineering and technology. Each of the top 10 materials has unique properties that maintain performance in extreme conditions. While some, such as Hafnium Carbonitride and Tantalum Hafnium Carbide, reach temperatures above 4000°C, others such as graphite and tungsten offer excellent performance at slightly lower thresholds. Experts utilise these materials in applications ranging from aerospace engines and turbine blades to high-temperature furnaces and advanced electronics.

Frequently Asked Questions

F: What makes a material high temperature resistant?

Q: Its atomic structure and bonding provide strong thermal stability.

F: Are these materials used in commercial industries?

Q: Yes, they are employed in aerospace, energy, and industrial furnace applications.

F: Can high-temperature materials be easily manufactured?

Q: They require advanced techniques and controlled environments for processing.

Reference

[1] Tungsten. (2025, August 27). In Wikipedia.

[2] Rhenium. (2025, July 29). In Wikipedia.

[3] Osmium. (2025, September 3). In Wikipedia.

[4] Tantalum. (2025, August 13). In Wikipedia.

[5] Molybdenum. (2025, September 2). In Wikipedia.

[6] Niobium. (2025, September 3). In Wikipedia.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento