Various Niobium Forms In Superconducting And Vacuum Systems

Introduction

Niobium is valued by engineers and scientists for its high purity and corrosion resistance. This article provides an overview of various forms of niobium used in superconducting and vacuum systems.

Niobium Forms and Their Applications

- Foil

Niobium Foil is used in superconducting thin-film circuits. It is also employed as a shielding material in electromagnetic environments. Thin foils enable the production of compact circuits with minimal interference requirements. The high conductivity helps maintain performance across a range of temperatures.

- Plates

Niobium plates are used in superconducting radio frequency cavities utilised in particle accelerators and cryogenic systems. These plates are also used in the manufacture of vacuum flanges and other accelerator components. Given that their strength withstands mechanical loads, they meet the demands of ultra-high vacuum environments.

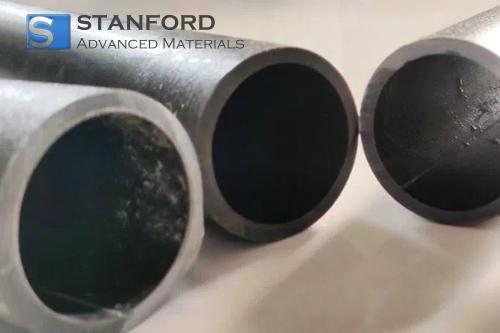

- Tube

Niobium tubes are frequently used in cryogenic piping. They incorporate helium-cooling channels used to maintain the low temperatures required by superconducting magnets. The smooth interior surface permits efficient liquid flow and reduces the risk of blockages. The tubes are known for their corrosion resistance in cryogenic environments.

- Bars

Niobium bars serve as the starting material for niobium-titanium wires. These wires are used in superconducting magnets for medical imaging devices. The bars also function as structural supports in assemblies. Their performance under heavy loads makes them a preferred material for precision instruments.

- Target

The target form of niobium is generally used for sputtering applications. Superconducting layers based on niobium, such as niobium nitride and niobium-titanium nitride, are produced. These layers are used in thin-film applications where specific performance and durability are required. They are widely employed in modern superconducting electronics.

- Mesh

Niobium mesh is chosen when controlling electromagnetic interference is necessary. The porous structure permits effective vacuum filtration. Its high strength and low mass are advantageous when both minimal weight and efficient shielding are required.

- Crucible

Niobium Crucible is used for melting high-purity alloys under vacuum or inert atmospheres. It is suitable for high-temperature applications that require a contamination-free environment. The design of the crucible ensures that the melt is not exposed to oxidation or unwanted impurities during processing.

Performance Requirements

For effective operation in high-technology systems, niobium must be very pure – generally 99.95% or above. Even minimal impurities can alter its electrical behaviour, particularly in superconducting applications.

A smooth surface is also important. It aids thin-film deposition and reduces gas generation in vacuum systems. This helps ensure that these systems remain clean and stable.

Weldability and machinability are essential. Niobium should be easily formed and joined, thereby allowing engineers to manufacture precise and reliable components.

In vacuum environments, controlling gas adsorption is critical. The stable surface of niobium helps prevent gas release, thereby protecting sensitive equipment.

Case Studies

Numerous high-technology facilities depend on niobium in their critical systems. Particle accelerators at institutions such as CERN and the Spallation Neutron Source utilise niobium components in accelerator cavities and vacuum flanges. This measure ensures stable operation under extreme conditions.

Magnetic resonance imaging devices in hospitals employ superconducting magnets. These magnets are based on niobium-titanium wires derived from high-quality niobium bars. The performance of MRI systems is closely linked to the properties of these materials.

Niobium also benefits quantum information research. Thin-film devices made of niobium are standard components in experimental setups. Their superconducting properties support low-energy, high-speed operation in quantum circuits.

Conclusion

Niobium is indispensable for modern superconducting and vacuum systems. Its combination of high purity, corrosion resistance, low vapour pressure and reliable superconducting properties makes it essential. From foils and plates to tubes, bars, targets, mesh and crucibles, each form meets specific requirements in the high-technology industry. These applications are critical for particle accelerators, medical imaging devices and quantum computers. The performance characteristics and versatility of niobium underpin its role as a key material in advanced technical fields.

Frequently Asked Questions

Q: Why is niobium suitable for superconducting systems?

Q: Its high purity, corrosion resistance, low vapour pressure and reliable superconducting properties.

Q: Why are different forms of niobium used in various applications?

Q: Different forms meet specific requirements in thin-film circuits, vacuum components and cryogenic systems.

Q: How does niobium contribute to the performance of vacuum systems?

Q: It provides a smooth surface, controlled gas release and effective weldability for reliable connections.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento