What Is the Highest Melting Point Metal?

Melting Point Chart

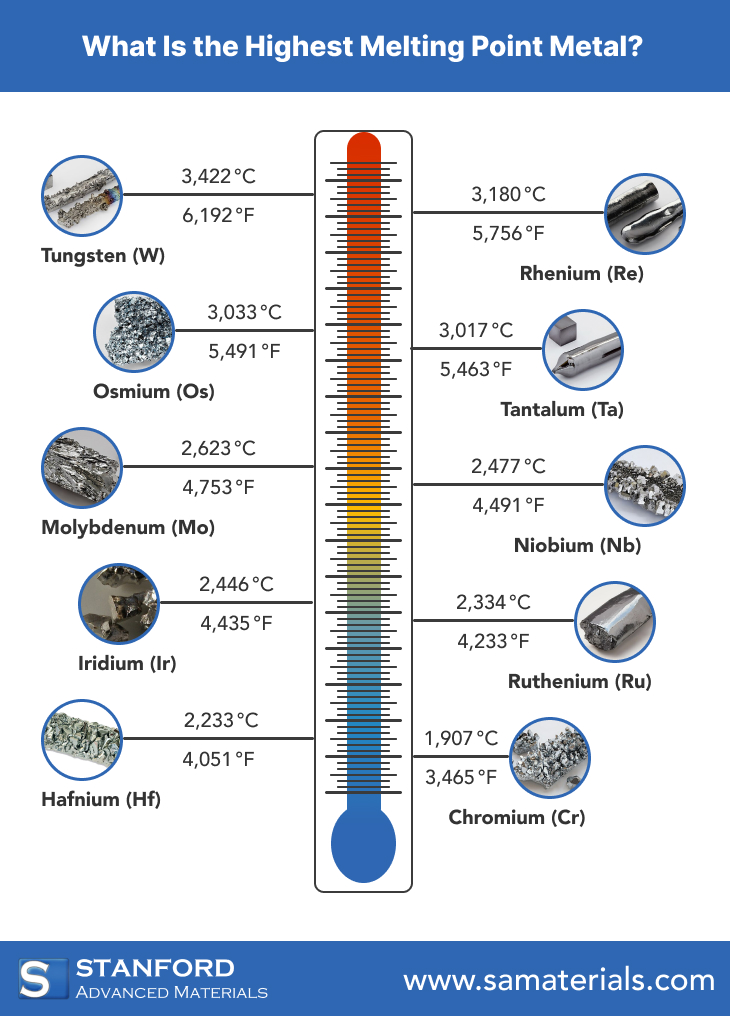

When we discuss melting points, we refer to the temperature at which a solid transitions to a liquid. In metals and alloys, these values differ significantly. Some metals melt at exceptionally high temperatures, making them suitable for high-temperature applications. Others melt at lower temperatures and are utilised in everyday items.

Melting points depend on atomic structure and bonding strength. Refractory metals are recognised for their high melting points. They are employed in applications such as aerospace, electronics, and high-temperature environments. The chart below illustrates the top ten metals with the highest melting points to assist you in understanding their importance and application.

Further reading: Top 5 High-Temperature Resistant Metals and Their Key Applications

Top 10 High Melting Point Metals

The following is a list of the top ten high melting point metals. Each entry displays the metal name along with its melting point in Celsius and Fahrenheit.

1. Tungsten (W) – 3,422°C / 6,192°F

Tungsten holds the record for the highest melting point among pure metals. It is known for its strength and stability at high temperatures. Tungsten is utilised in light bulb filaments and rocket engine nozzles.

2. Rhenium (Re) – 3,180°C / 5,756°F

Rhenium is a rare metal with a high melting point. It finds application in jet engines and in the production of superalloys. Its capacity to withstand high heat makes it valuable in demanding conditions.

3. Osmium (Os) – 3,033°C / 5,491°F

Osmium ranks as one of the densest elements with a high melting point. Its hardness and wear resistance enable its use where strong, hard materials are required. It is applied in electrical contacts and fountain pen nibs.

4. Tantalum (Ta) – 3,017°C / 5,463°F

Tantalum exhibits high resistance to heat and corrosion. It is commonly used in electronic components such as capacitors and high-temperature alloys. Its stability in challenging conditions renders it a reliable component in numerous devices.

5. Molybdenum (Mo) – 2,623°C / 4,753°F

Molybdenum plays a crucial role in steel alloys for enhancing strength and heat resistance. It is employed in tools and automotive parts experiencing high thermal stress. Its performance in demanding environments is well established.

6. Niobium (Nb) – 2,477°C / 4,491°F

Niobium is recognised for its consistent melting point and resilience. It is employed to enhance steel and in superconducting materials. Typical applications include medical devices and high-speed trains.

7. Iridium (Ir) – 2,446°C / 4,435°F

Iridium is another rare metal that withstands high temperatures. Its high melting point and corrosion resistance make it suitable for harsh chemical environments. Industrial spark plugs and crucibles frequently utilise iridium.

8. Ruthenium (Ru) – 2,334°C / 4,233°F

Ruthenium is part of the platinum group metals. It acts as a hardening agent in platinum and palladium alloys. This metal holds value in electronics and chemical industry equipment.

9. Hafnium (Hf) – 2,233°C / 4,051°F

Hafnium serves a function in nuclear reactors due to its capability to absorb neutrons. It is also combined with other metals to form robust alloys that perform effectively at high temperatures. Its resistance to melting under stress is notable.

10. Chromium (Cr) – 1,907°C / 3,465°F

Chromium is widely recognised for its function in stainless steel. It provides corrosion resistance and strength. Although it has the lowest melting point on this list, it remains essential in numerous industrial sectors.

Conclusion

Metals with high melting points have a long-standing presence in industrial applications. The metals outlined above form the foundation for many critical uses. When engineers design components that must endure extreme heat, they select these metals to ensure stability and performance. Whether in aircraft engines, power plants, or during the forging process, the temperature limits of metals significantly influence their applications. For more advanced materials, please visit Stanford Advanced Materials (SAM).

Frequently Asked Questions

F: Which metal has the highest melting point?

Q: Tungsten possesses the highest melting point among pure metals.

F: Why are metals with high melting points significant?

Q: They are essential for high-temperature applications and durable engineering components.

F: Can alloys have higher melting points than pure metals?

Q: In general, alloys are formulated for enhanced strength but seldom exceed the highest melting temperature of pure metals.

Reference

[1] Tungsten. (2025, August 27). In Wikipedia.

[2] Rhenium. (2025, July 29). In Wikipedia.

[3] Osmium. (2025, September 3). In Wikipedia.

[4] Tantalum. (2025, August 13). In Wikipedia.

[5] Molybdenum. (2025, September 2). In Wikipedia.

[6] Niobium. (2025, September 3). In Wikipedia.

[7] Iridium. (2025, August 28). In Wikipedia.

[8] Ruthenium. (2025, August 23). In Wikipedia.

[9] Virginia Department of Energy. (2025, September 5). Hafnium. Retrieved 5 September 2025.

[10] Chromium. (2025, August 9). In Wikipedia.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento