Case Study: How YSZ Improved ZSBN Nozzle Durability

Introduction

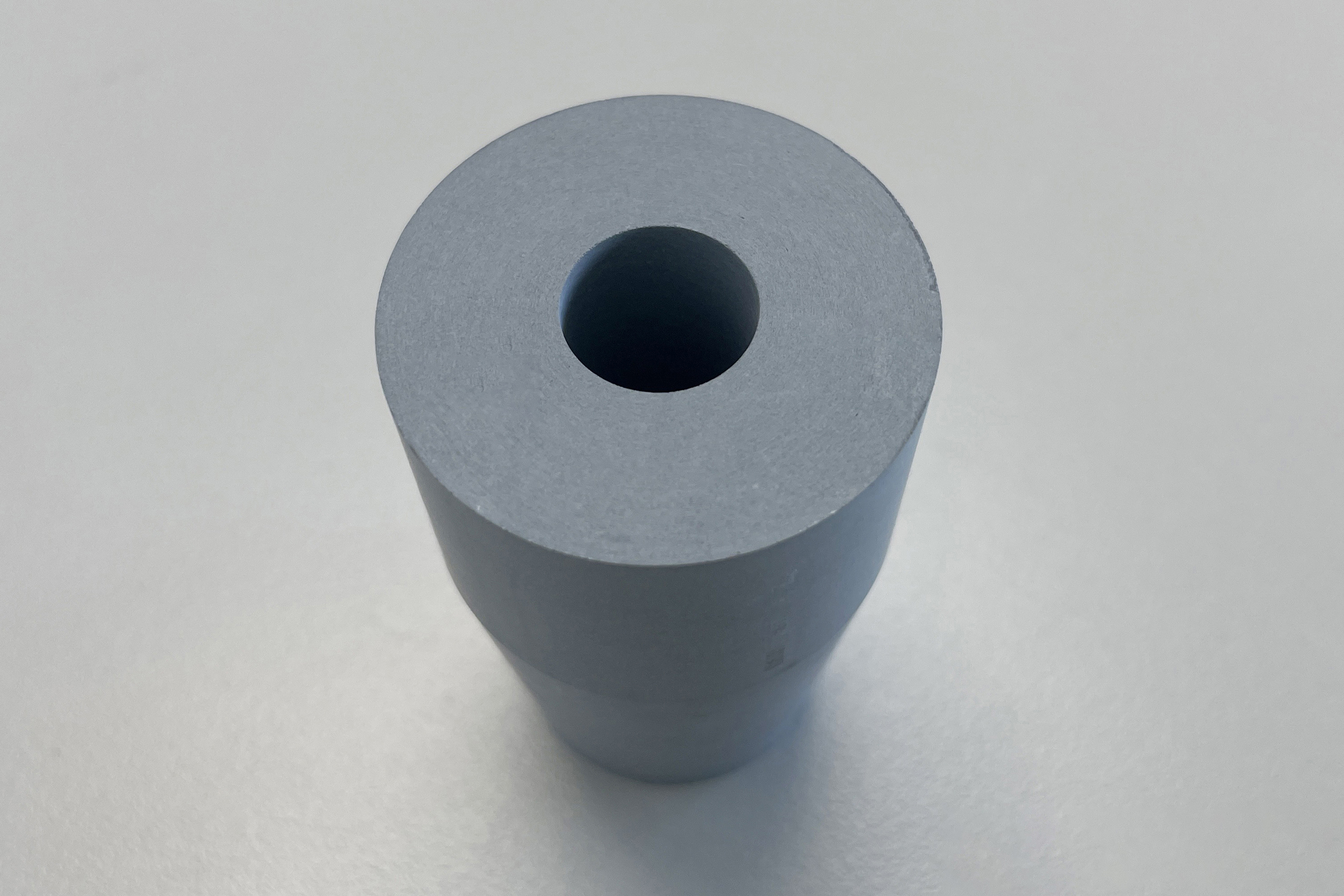

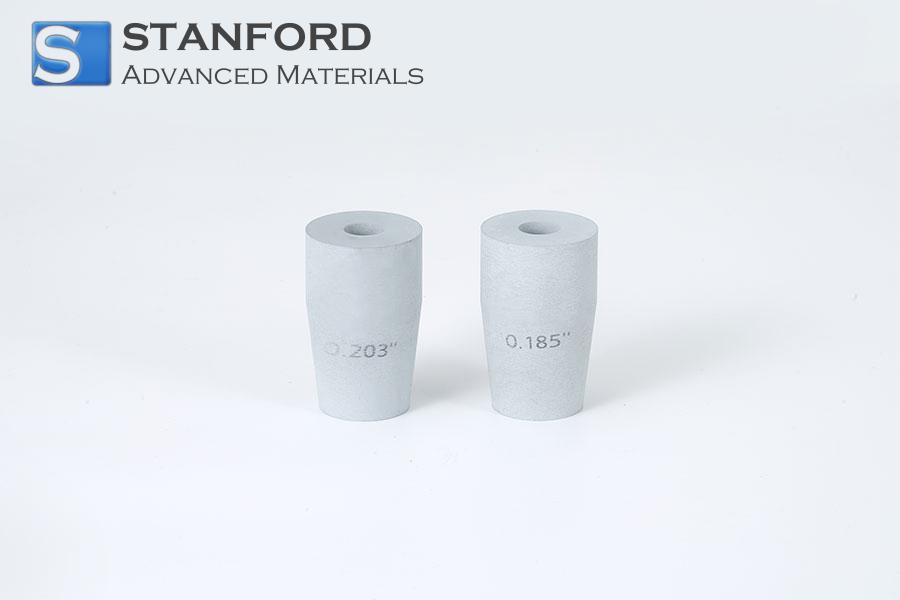

This case study describes how Stanford Advanced Materials (SAM) addressed a client's requirement for extended operating hours of ZSBN nozzles in high-temperature and high-wear conditions. Adjustments were made to both the ceramic formulation and forming parameters, thereby improving resistance to abrasion and reducing thermal degradation without materially affecting cost.

Background

ZSBN (Zirconia Strengthened Boron Nitride) nozzles are extensively employed in thermal spray, molten metal handling and other industrial processes where elevated temperatures and abrasive conditions persist. One client reported that nozzles produced with standard ZrO₂‐reinforced BN did not meet the required service life. Failures occurred at operating temperatures exceeding 1 000 °C in systems using fast-moving abrasive media. Frequent replacements resulted in increased downtime and maintenance expenditure.

The client initially utilised a formulation with unstabilised zirconia. The objective was to enhance durability under cyclical thermal and mechanical loads encountered during regular operation.

Core Challenge

The primary issue involved premature wear and thermal cracking of the nozzle material. Although the BN matrix provides lubricity and thermal resistance, the original additive system did not deliver adequate phase stability or mechanical toughness at elevated temperatures. A reinforcement phase with improved high-temperature behaviour was required, provided that brittleness was not introduced and machinability remained acceptable.

Evaluated Solutions

Option 1: Retain original zirconia additive, adjust pressing process

-

Pros: Limited modifications to raw material sourcing and the firing schedule.

-

Cons: Only modest improvements in thermal endurance and wear resistance were achievable.

Option 2: Replace with yttria-stabilised zirconia (YSZ)

-

Pros: Enhanced phase stability above 1 000 °C, improved wear resistance and increased grain boundary integrity.

-

Cons: A slightly higher material cost and modified mixing and sintering protocols are required.

Option 3: Apply protective coatings to the nozzle surface

-

Pros: Provides a surface-level barrier to abrasion.

-

Cons: Involves a complex manufacturing process; the coating may delaminate at high temperatures and increases production costs.

Selected Approach: Option 2 – The standard zirconia was substituted with 3 mol% YSZ, accompanied by minor adjustments to the forming process.

Solution & Implementation

YSZ at 3 mol% was incorporated as the reinforcement phase within the BN matrix. YSZ maintained phase stability above 1 000 °C and contributed to retarding crack propagation under load. In addition to the material substitution, the cold isostatic pressing (CIP) stage was modified as follows:

-

Pressing time: The hold time was increased from 30 s to 60 s.

-

Powder feedstock: A higher-density YSZ-BN composite powder blend was employed.

-

Sintering: The original sintering schedule was maintained to control energy costs.

These modifications yielded improved green density and a more consistent sintered microstructure.

"Measured modifications included improved particle packing, utilisation of a more stabilised reinforcing phase and closer control during forming. Subsequent testing indicated measurable performance enhancements," said Lisa Ross, Senior Ceramics Engineer at SAM.

Results & Feedback

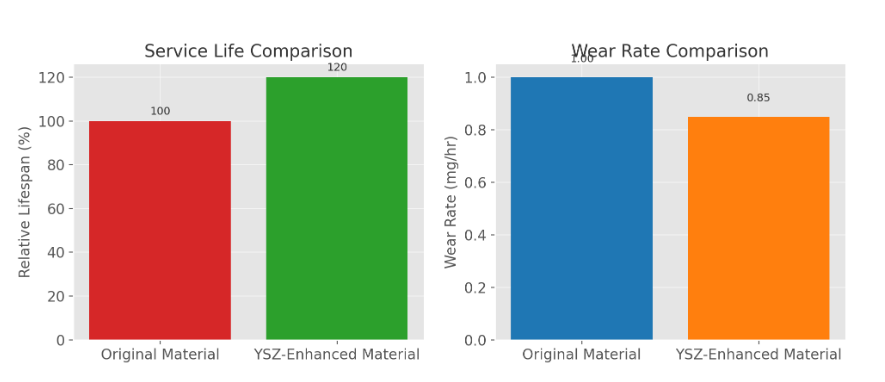

Performance Metrics

| Property | Original Nozzle | Optimised Nozzle | Improvement |

|---|---|---|---|

| Wear resistance (relative) | 100% (baseline) | Approximately 112–115% | +10–15% |

| Thermal stability (>1 000 °C) | Moderate | High | Significantly enhanced |

| Service life in application | Approximately 40 operating hours | Approximately 48–50 operating hours | +20–25% |

Client Feedback

The client reported a 20–25% increase in nozzle service life under consistent operating conditions. Maintenance intervals were extended and unplanned downtime was reduced. The revised formulation has been approved for implementation on two further production lines.

"The upgraded nozzles have resulted in a stabilised spray system and reduced unplanned stops. The performance data clearly reflect these improvements." – Client production manager

Recommendations & Future Work

-

Adopt the YSZ-based formulation for production nozzles

-

Continue monitoring long-term performance under varied load cycles

-

Examine the impact of sintering temperature optimisation in future batches

SAM will maintain collaboration with the client to refine material properties as required and to provide technical support during the scale-up of the enhanced nozzles.

Conclusion

This project demonstrates that targeted material substitutions combined with defined forming adjustments can yield quantifiable durability improvements. By substituting conventional zirconia with YSZ and increasing the pressing hold time, Stanford Advanced Materials (SAM) has improved both the thermal and mechanical performance of the ZSBN nozzle system.

The revised nozzles deliver extended service life, improved resistance to demanding process conditions and a reduction in total ownership costs for the client. Have any questions or require further details on your specific needs? Send us an enquiry to receive technical solutions and guidance.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento