All About Molybdenum Wire And EDM Wire Cutting

In the field of precision machining every thousandth of a millimetre is critical. In electrical discharge machining (EDM), where metal is removed by controlled sparks, the type of wire used is crucial. Molybdenum wire has demonstrated measurable improvements in this process.

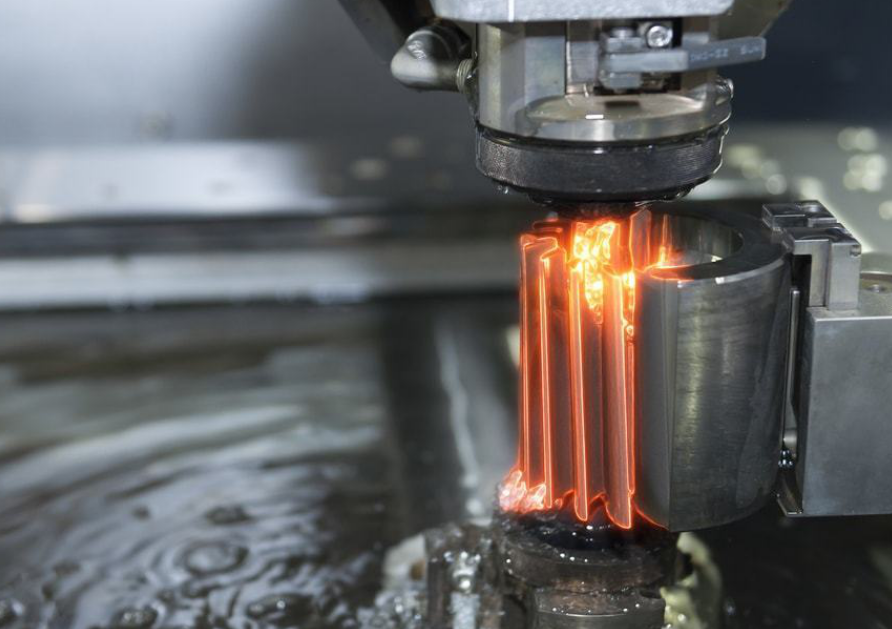

Fig. 1 EDM machining

EDM Wire Cutting – Fundamentals

What is distinctive about wire electrical discharge machining?

Wire electrical discharge machining (EDM) is a non-contact cutting process in which material is removed by electrical discharges (sparks). This method enables the cutting of even the hardest metals without applying mechanical force. It avoids mechanical loading and tool wear that occur in conventional cutting and achieves fine tolerances.

In wire EDM a thin metal wire serves as the electrode. When the wire approaches the workpiece, electrical discharges produce significant heat that vapourises or melts the material. This method is used in tool and mould making, the aerospace sector and for high-precision components.

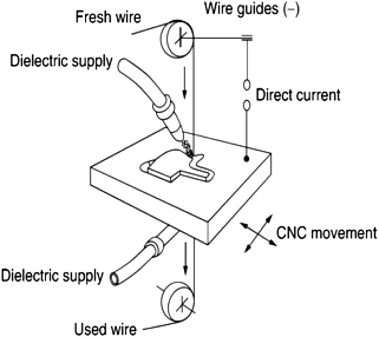

EDM Wire Cutting Components

The system consists of a wire (commonly brass or molybdenum), a dielectric fluid (typically deionised water), a power supply and a computer-controlled motion system. The choice of wire affects parameters such as cutting speed, dimensional tolerance and cost.

[1]

[1]

Fig. 2 Components of EDM wire cutting

Molybdenum Wire for Electrical Discharge Machining

Why use molybdenum wire?

Molybdenum is a metal with a high melting point (approximately 2 620°C), high tensile strength and good electrical conductivity. Consequently, it is advantageous for wire EDM.

1. Reusability and Durability

Unlike brass, molybdenum wire is recyclable. It is repeatedly used in most Asian EDM machines (for example, the DK77 series), often for hundreds of cycles before it loses its cutting edge. This results in reduced overall wire consumption and lower maintenance costs over the long term.

2. Clean, precise cuts

Due to its tensile strength and resistance to thermal deformation, molybdenum wire maintains its form. It provides constant tension, thereby yielding clean cuts and tighter tolerances when machining hard materials such as titanium or hardened tool steel.

3. Faster cutting with fewer breaks

Molybdenum wire facilitates faster cutting cycles because it does not break under tension and heat. This efficiency is particularly beneficial in the aerospace and electronics sectors, where precision and reduced downtime are critical.

4. Ideal for narrow and detailed gaps

When exact geometries are required, molybdenum wire retains its form and does not bend. This ensures it performs well in sharp corners and with complex three-dimensional profiles.

[2]

[2]

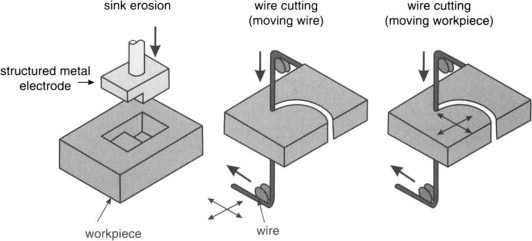

Fig. 3 EDM wire cutting process

When should molybdenum wire be used?

Although molybdenum wire has higher acquisition costs per metre than brass wire, its reusability often results in lower overall costs over time. It is the wire of choice for:

- Repeated production runs

- Materials with high hardness (carbide, Inconel, tool steels)

- Work requiring tight tolerances

- Applications in aerospace, defence, medical technology and tool/mould making

However, molybdenum wire is not suitable for EDM machines with continuous feed, as are common in many western workshops. It is primarily used in reciprocating EDM systems that support a back-and-forth wire movement.

Considerations

Like every tool, molybdenum wire has limitations. Consider the following points:

- Not suitable for machines with continuous feed: Most western wire EDM systems are incompatible.

- Wire diameter is crucial: Common diameters range from 0.10 mm to 0.20 mm. Adjust the size according to the detail and the material of your project.

- Wire tension is critical: Proper wire tension ensures precise cuts and prevents wire breakage.

- Reconditioning is required: Although molybdenum wire lasts longer, it wears over time. Monitor for signs of reduced cutting quality and replace if necessary.

Electrode Materials for EDM Wire Cutting

|

Wire type |

Key Characteristics |

Most Suitable For |

|

Brass wire |

Cost-effective, straightforward to use, good electrical conductivity |

General cutting, EDM machines with continuous feed |

|

High strength, heat resistant, reusable |

High-precision cutting or machining of hard materials, EDM systems with reciprocating feed |

|

|

Tungsten wire |

High density, reasonably heat resistant |

Micro-EDM, high-temperature or ultraprecision applications |

|

Coated/diffused wire |

Brass with zinc or treated to enhance cutting speed and surface finish |

Modern high-speed EDM machines, fine surface machining |

|

Copper wire |

High electrical conductivity, soft material |

Older machines, smooth finish for delicate parts |

|

Hybrid/Composite wire |

Multiple materials |

Optimised for applications requiring speed, accuracy and durability |

For further information and technical support please consult Stanford Advanced Materials (SAM).

Frequently Asked Questions

1. Can I use molybdenum wire on every EDM machine?

Not directly. It is primarily used on machines designed for reciprocating or back-and-forth wire systems, particularly in Asian EDM systems.

2. Is molybdenum wire more expensive than brass wire?

Yes, on a per metre basis; however, as it is reusable, overall costs tend to be lower over time.

3. For what types of parts is molybdenum wire best suited?

It is most suitable for small, complex or high-precision parts made from hard materials – such as dies, moulds or fine components in aerospace and electronics.

References:

[1] Amitesh Goswami, Jatinder Kumar, Optimization in wire-cut EDM of Nimonic-80A using Taguchi's approach and utility concept, Engineering Science and Technology, an International Journal, Volume 17, Issue 4, 2014, Pages 236–246, ISSN 2215–0986, https://www.sciencedirect.com/science/article/pii/S2215098614000524

[2] Matthias Worgull, Chapter 9 – Microstructured Mold Inserts for Hot Embossing, Editor(s): Matthias Worgull, in Micro and Nano Technologies, Hot Embossing, William Andrew Publishing, 2009, Pages 283–306, ISBN 9780815515791, https://www.sciencedirect.com/science/article/pii/B978081551579150015X

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento