Comparative Analysis Of Tantalum, Niobium, And Pt/Ir Capillary Tubes In Medical Applications

Introduction

Capillary tubes fabricated from Tantalum (Ta), Niobium (Nb) and Platinum-Iridium (Pt/Ir) alloys are integral components in various medical devices, particularly in interventional cardiology, neurosurgery and implantable electronic devices. These metals are selected based on their mechanical properties, biocompatibility, radiographic visibility and long-term stability within the human body.

This article examines the physical and chemical properties of these three materials, assesses their suitability for specific medical applications and provides practical examples from clinical environments.

1. Material Properties at a Glance

|

Property |

Niobium (Nb) |

||

|

Density (g/cm³) |

16.6 |

8.6 |

~21.5 |

|

Melting Point (°C) |

3017 |

2477 |

~1780 (Pt) |

|

Radiopacity (X‑ray) |

High |

Moderate |

Very high |

|

Biocompatibility |

Excellent |

Excellent |

Excellent |

|

Corrosion Resistance |

Excellent |

Very good |

Excellent |

|

Magnetic Response |

Non-magnetic |

Non-magnetic |

Non-magnetic |

|

Cost |

Moderate-high |

Moderate |

High |

Further reading: Capillary Tubes: Types and Applications

2. Tantalum: The Established Choice for Long-Term Implants

Tantalum capillary tubes are employed due to their excellent biocompatibility, high corrosion resistance and significant X‑ray visibility. Their practical applications include:

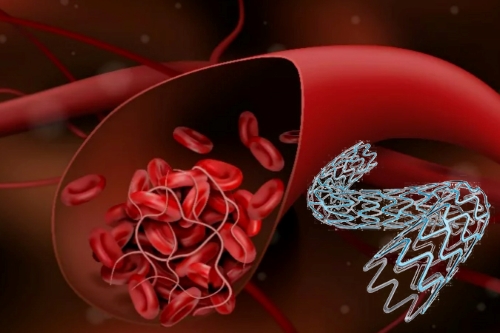

- Coronary stents: Tantalum is used for X‑ray marker strips in balloon catheters and stents. Given its high density, it is easily discernible under X‑ray imaging.

- Spinal fusion devices: Tantalum cages promote osseointegration while maintaining mechanical strength and chemical inertness.

- Cranial reconstruction plates: Owing to its compatibility with bone tissue and non‑magnetic properties, it is favoured in neurosurgical procedures.

- Cochlear implants: Tantalum tubes facilitate signal conduction over several decades with stability within the body.

3. Niobium: A Balanced Option for Electronics and Temporary Implants

Niobium capillary tubes are lighter and simpler to manufacture than those made from Tantalum while maintaining excellent biocompatibility. They are particularly useful in devices requiring electrical insulation, electromagnetic transparency or tight tolerances.

The practical applications include:

- Implantable pulse generators (IPGs): Niobium is frequently used for housings or connectors in pacemakers and neurostimulators owing to its non‑magnetic and electrically neutral properties.

- Neurostimulation leads: Its flexibility and corrosion resistance make niobium suitable for fine-diameter leads that transmit electrical signals.

- Cochlear implant connectors: These connectors benefit from niobium’s solderability and form stable interfaces with silicone or epoxy capsules.

4. Platinum-Iridium: High Performance for High‑Risk Applications

Platinum-Iridium alloys (typically 90/10 or 80/20 Pt/Ir) are employed in components that require high radiopacity, electrical conductivity and corrosion resistance.

Their practical applications include:

- Electrophysiology catheters (EP catheters): Pt/Ir tips function as electrodes to transmit or record cardiac signals during ablation procedures.

- Vascular marker rings: In cerebral aneurysm coils or embolisation devices, Pt/Ir rings provide clear radiographic visibility to support precise placement.

- Deep brain stimulation (DBS): Fine Pt/Ir tubes are used to encapsulate or support implanted electrodes in the brain.

- RF ablation devices: The electrical conductivity and thermal stability of Pt/Ir are critical under operational loads.

5. Guide to Selecting Applications

|

Medical Application |

Recommended Material |

Reason |

|

Coronary balloon markers |

Cost‑effective and radiographically visible |

|

|

Electrodes for neurostimulators |

Niobium |

Flexible, biocompatible and electromagnetically stable |

|

Deep brain stimulation (DBS) |

Pt/Ir |

Fine electrodes and high electrical conductivity |

|

Spinal implants |

Tantalum |

Encourages osseointegration |

|

Electrodes for cardiac ablation |

Pt/Ir |

High thermal stability and conductivity |

|

Cochlear implant components |

Niobium or Tantalum |

Biocompatible and solderable |

|

Markers for aneurysm coils |

Pt/Ir |

High radiopacity and corrosion resistance |

For further information, please visit Stanford Advanced Materials (SAM).

Conclusion

Each of these materials – Tantalum, Niobium and Pt/Ir – has established its role in the medical technology sector. The selection should be based not only on technical performance but also on cost, regulatory history and the integration with other device components.

- Utilise Tantalum capillary tubes when long‑term implantation, X‑ray visibility and mechanical strength are required.

- Select Niobium for light, flexible and electrically neutral components; this is ideal for electronic applications and implants intended for short to medium durations.

- Opt for Platinum-Iridium in applications that require precise, radiographically opaque and electrically active components, particularly in neurology and cardiology.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento