Stanford Advanced Materials Provided CBN Solutions For Aerospace Tooling

Introduction

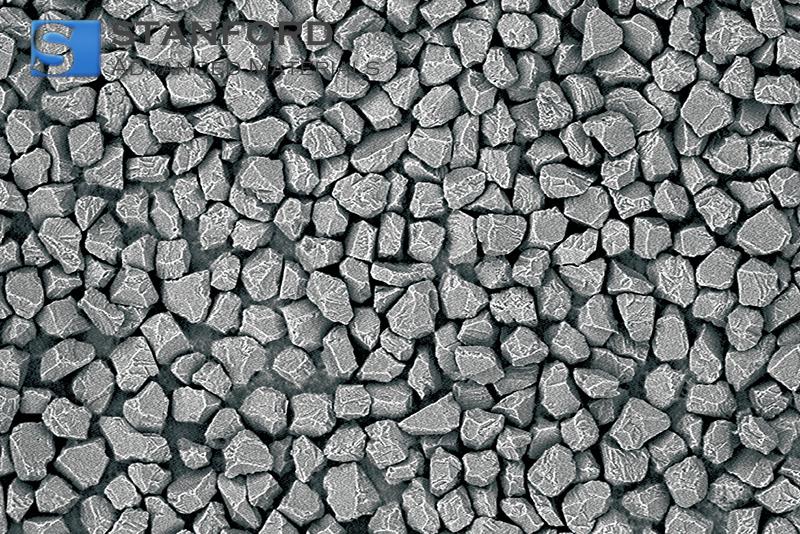

Stanford Advanced Materials (SAM) publishes a documented case study on the use of cubic boron nitride (cBN), a material that exhibits high hardness and maintains a defined thermal stability as well as chemical inertness. SAM’s cBN solutions helped a recognised aerospace manufacturer address significant tool wear in machining hardened iron alloys.

The leading ceramics engineer at SAM, Lisa Ross, explained:

"Cubic Boron Nitride provides engineers with measurable benefits, particularly in situations where diamond tools react with iron. This solution meets the application-specific requirements for machining refined metals."

Case Study on Cubic Boron Nitride

--The Challenge: Tool Wear in Machining Aerospace Components

A large aerospace parts manufacturer informed SAM of a critical issue. The company’s production lines for machining hardened steel and nickel-based super alloys for engine components experienced extensive tool wear. Even coated carbide tools failed, and diamond tools reacted with the iron-based materials.

The principal issues were:

- Frequent tool changes that interrupted production

- Edge wear resulting in loss of dimensional tolerance

- Excessive heat generation during high-speed machining

- Increased costs due to the short service life of the tools

The customer required a product with high temperature endurance, resistance to chemical wear and the ability to maintain a sharp edge under extreme machining conditions.

--SAM’s Solution: Cubic Boron Nitride Inserts and Powder

After a detailed review of the application, Stanford Advanced Materials recommended its range of cubic boron nitride (cBN) products. The company offers high-purity cBN powder developed for manufacturing sintered cutting tools, along with pre-manufactured cBN cutting inserts designed for machining iron-based alloys.

Why use cubic boron nitride (cBN)? Firstly, cBN exhibits a hardness that is exceeded only by diamond, resulting in a quantifiable wear resistance. Additionally, cBN maintains its performance at temperatures up to 1 350 °C in air. It is chemically inert; consequently, it does not react with iron or steel. Finally, cBN maintains edge stability during dry or high-speed machining, thereby extending tool life and ensuring consistent performance. These factors make cBN a suitable material for demanding industrial applications.

SAM also provided technical guidance in tool selection, establishing machining parameters and integrating the CNC operations. The objective was to optimise tool life without compromising dimensional accuracy or repeatability in high-volume production.

-Implementation and the Results

The aerospace manufacturer implemented SAM’s cBN tools in the finishing operations of turbine blades and structural steel hangers. The performance results were as follows:

- Tool life increased by 4.5 times, thereby reducing the frequency of tool changes and downtime

- Machining cycle times were reduced by 18% as a result of increased cutting speeds

- Surface finish and dimensional tolerances improved to meet aerospace standards

- Overall tool costs were reduced by 32% during the six-month trial period

These quantified results led the manufacturer to adopt cBN tools across its production lines for high-alloy materials. Consequently, the improved performance enabled engineers to achieve shorter lead times, lower scrap rates and reduced rework.

What is Cubic Boron Nitride?

Cubic boron nitride (cBN) is a synthetic material with a cubic crystal structure, similar to that of diamond. It is employed in high-precision machining where defined hardness and thermal stability are required. cBN does not react with iron-based materials and is therefore suitable for machining hardened steels, cast irons and super alloys.

The key properties of cBN are outlined below:

|

Feature |

Value |

|

Hardness |

~4500 kg/mm² (Vickers) |

|

Thermal Stability |

Up to 1 350 °C in air |

|

Electrical Resistivity |

>10⁶ Ω-cm |

|

Chemical Resistance |

Inert to iron, steel and nickel alloys |

|

Machinability |

Suitable for precision lapping and grinding |

SAM’s cBN products are designed to meet the requirements of the aerospace, automotive and modern manufacturing sectors. They are available as powders, sintered inserts or composite materials.

Read more: Why is cubic boron nitride described as a superhard material?

Applications of Cubic Boron Nitride

Cubic boron nitride (cBN) is employed in a range of applications.

- It is used in machining tool steels, hardened steel and high-strength alloys owing to its high wear resistance and hardness.

- cBN is utilised in precision grinding tools for aerospace and automotive components where accuracy and durability are essential.

- It is applied as a wear-resistant coating on moulds and forming tools to extend their service life.

- cBN is incorporated in heat-resistant components designed for high-speed machining applications.

- It is typically selected when diamond and carbide tools are not applicable.

Conclusion

Cubic boron nitride (cBN) is a material of significant value for machining applications due to its defined combination of high hardness, thermal stability and chemical resistance. Stanford Advanced Materials (SAM) is a recognised provider of technical ceramics and hard materials. For further information on SAM’s cBN products or to request a tailored quote, please visit our Homepage.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento