Why Is Cubic Boron Nitride Called A Superhard Material?

Why is cubic boron nitride designated as a superhard material? If you seek an answer to this query, you have reached the correct resource. This article examines cubic boron nitride in detail and explains why it is classified as a superhard material.

Why is cubic boron nitride designated as a superhard material?

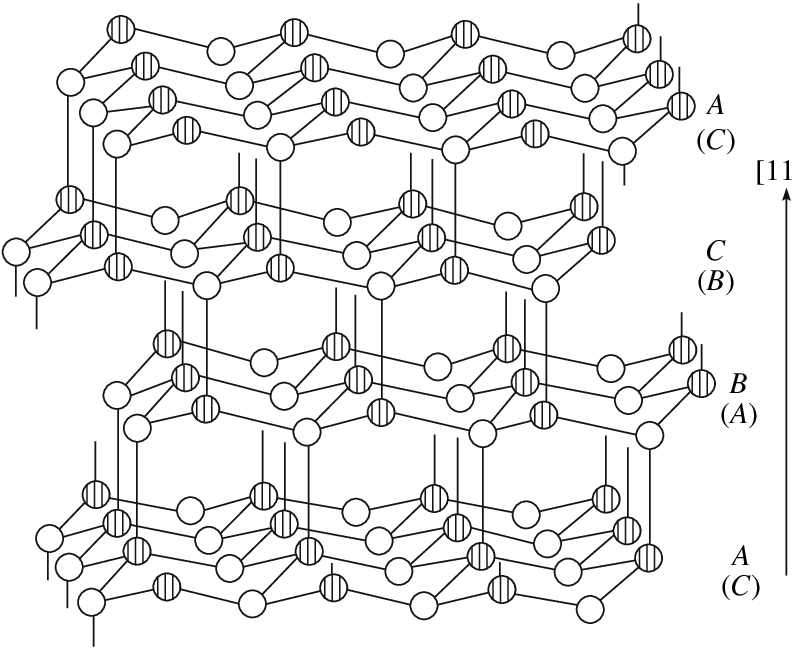

Cubic boron nitride (CBN) is a superhard material. It is synthesised from hexagonal boron nitride and a catalyst at high pressure and high temperature. Its hardness ranks second only to diamond in industrial applications. The thermal stability of CBN is higher than that of diamond. It also exhibits increased chemical stability when in contact with ferrous elements. Consequently, cutting and grinding tools made from CBN are used for machining ferrous materials, thereby delivering consistent performance.

There exist two forms of cubic boron nitride: single-crystal and polycrystalline sintered bodies. The single crystal is produced by controlling hexagonal boron nitride and catalyst parameters at pressures from 3 000 to 8 000 Mpa and temperatures from 800 to 1 900 °C. Typical catalyst materials include alkali metals, alkaline earth metals, tin, lead, antimony and their nitrides. The crystal morphology may be tetrahedral, truncated octahedral, inclined or twinned. Commercial CBN appears in black, amber and gold colours, with particle sizes typically below 1 mm.

Application of Boron Nitride Polycrystals in Metal Machining

The tool made from cubic boron nitride polycrystal (PCBN) is produced by sintering many fine CBN grains ranging between 0.1 and 100 µm. In addition to its hardness and wear resistance, it offers increased toughness and chemical inertness. A diamond grinding wheel may be used to polish its cutting edge. It performs consistently in machining operations and maintains stability at high temperatures. Consequently, PCBN is suited for machining hardened steel, tool steel, cast iron and other high-hardness materials.

Application of Cubic Boron Nitride in Grinding

Cubic boron nitride exhibits excellent grinding performance. It completes the processing of difficult-to-grind materials and improves processing productivity. It precisely controls the shape and size of the workpiece. It also enhances the surface integrity after grinding. The fatigue resistance of parts increases and their service life extends. Cubic boron nitride may be regarded as marking the second significant improvement in grinding technology.

Cubic Boron Nitride Powder is suitable for resin, metal, ceramic and other binder systems. It is used in the manufacture of polycrystalline composite materials and may serve as free abrasive particles or as a component in a grinding paste. As an abrasive, cubic boron nitride shows extended wear resistance. However, single-crystal cubic boron nitride presents defects such as a small grain size, anisotropy and a cleavage plane that is prone to splitting.

Conclusion

We thank you for reading this article. We trust it assists in understanding why cubic boron nitride is classified as a superhard material.

If further information on boron nitride is required, please visit Stanford Advanced Materials (SAM) for additional details.

Stanford Advanced Materials (SAM) has over two decades of experience in producing and distributing boron nitride. Their products meet stringent research and production criteria. We are confident that SAM will serve as a reliable supplier and business partner for your organisation.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento